Big Rig ROCK Report 3.12: Laser 101.7 - Practical Applications

Table of Contents

Improving Vehicle Alignment with Laser Technology

Maintaining optimal wheel alignment is crucial for any vehicle, but especially for big rigs. Improper alignment leads to increased tire wear, reduced fuel efficiency, and compromised handling. Laser alignment technology offers a significant upgrade over traditional methods, providing unparalleled accuracy and efficiency.

Keywords: Truck Alignment, Laser Alignment, Wheel Alignment, Heavy Vehicle Alignment, Laser Measurement Tools

- Benefits of Laser Alignment:

- Improved Fuel Efficiency: Precise wheel alignment minimizes tire scrubbing, resulting in significant fuel savings over the lifespan of your tires. Studies show that misaligned wheels can decrease fuel economy by up to 10%.

- Enhanced Vehicle Handling and Stability: Proper alignment ensures optimal tire contact with the road, leading to improved steering response, reduced sway, and enhanced stability, especially important for large vehicles navigating challenging road conditions. This translates directly into increased safety.

- Reduced Accident Risk: Misaligned wheels can lead to unpredictable handling, increasing the risk of accidents. Laser alignment helps mitigate this risk by ensuring the wheels are precisely aligned, promoting safer driving.

- Extended Tire and Suspension Lifespan: Correct alignment distributes weight evenly across all tires and suspension components, reducing wear and tear and extending their lifespan. This reduces costly and time-consuming repairs and replacements.

- Superior Accuracy: Laser alignment systems offer far greater accuracy than traditional methods, ensuring optimal wheel alignment for maximum performance and safety. The precision offered by these systems eliminates guesswork and ensures consistent results.

Details: Modern truck maintenance garages utilize sophisticated laser alignment systems. These systems employ laser beams to precisely measure the angles and positions of the wheels, providing detailed data for adjustments. This is a significant improvement over older methods relying on visual inspection and mechanical gauges, which were prone to human error and less precise measurements. The ROI of investing in laser alignment technology is easily justifiable considering the savings in fuel costs, tire replacements, and reduced maintenance.

Precise Distance Measurement for Loading and Unloading

Accurate distance measurement is critical for efficient and safe loading and unloading of cargo. Laser distance meters provide quick and precise readings, eliminating guesswork and minimizing errors.

Keywords: Distance Measurement, Laser Distance Meter, Loading Efficiency, Unloading Efficiency, Truck Loading, Cargo Management

- Advantages of Laser Distance Meters:

- Optimal Weight Distribution: Accurate measurements ensure proper cargo placement for optimal weight distribution, preventing overloading or underloading. This is especially important for maintaining vehicle stability and avoiding fines.

- Reduced Risk of Overloading/Underloading: Precise measurements help avoid overloading, which can lead to safety hazards and legal issues, and underloading, which can be inefficient and costly.

- Streamlined Loading/Unloading: Laser distance meters speed up the loading and unloading process, saving valuable time and labor costs. Quick, accurate measurements mean less time spent measuring and more time spent moving cargo.

- Improved Safety: Accurate cargo placement minimizes the risk of shifting loads and associated accidents during transit. Knowing the precise dimensions and distances ensures safety for both the driver and the cargo.

- Versatile Use: Laser distance meters are useful for various tasks beyond cargo placement, including measuring distances for backing up and determining precise cargo dimensions.

Details: Imagine using a laser distance meter to precisely measure the distance between the trailer and the loading dock before backing up. Or using it to quickly verify the dimensions of a container before loading. These seemingly small efficiencies add up to significant time and cost savings over the long term.

Enhancing Road Safety with Laser-Based Systems

Laser technology plays a crucial role in enhancing road safety for big rigs. Advanced driver-assistance systems (ADAS) and other safety features rely on laser sensors for improved driver awareness and collision avoidance.

Keywords: Road Safety, Laser Sensors, Collision Avoidance, Blind Spot Detection, Truck Safety Technology, Driver Assistance Systems

- Laser-Based Safety Features:

- Blind Spot Detection: Laser-based systems provide accurate detection of vehicles in blind spots, significantly reducing the risk of lane changes accidents.

- Collision Avoidance Systems: Laser sensors can detect potential collisions and alert the driver, or even automatically initiate braking, preventing accidents.

- Advanced Driver-Assistance Systems (ADAS): ADAS features such as adaptive cruise control and lane keeping assist leverage laser technology for improved safety and driver support.

- Reduced Accident Rates: The implementation of laser-based safety features translates directly into lower accident rates, leading to lower insurance costs and improved overall operational efficiency.

- Autonomous Driving Technology: Laser technology is a cornerstone of autonomous driving systems for trucks, promising even greater safety improvements in the future.

Details: The integration of laser technology into modern truck safety systems is rapidly advancing. Autonomous emergency braking (AEB) systems, for example, utilize lasers to detect potential collisions and automatically apply the brakes. These advancements are crucial for improving road safety in the trucking industry. Statistics show a significant reduction in accidents attributable to the adoption of laser-based safety systems.

Laser Leveling for Construction and Heavy Haul

For trucking involved in construction and heavy haul, laser leveling is essential for precise and efficient operations. Laser-based leveling systems ensure accurate positioning and prevent costly errors.

Keywords: Laser Leveling, Truck Leveling, Construction Trucking, Heavy Haul Trucking, Grade Control, Site Preparation

- Benefits of Laser Leveling:

- Accurate Cargo Leveling: Laser leveling ensures precise leveling of cargo and trailers, even on uneven terrain. This is crucial for maintaining stability during transport.

- Improved Stability: Properly leveled cargo reduces the risk of shifting loads and improves overall vehicle stability, especially important during heavy haul operations.

- Optimized Load Distribution: Laser leveling helps optimize load distribution, maximizing efficiency and minimizing stress on the vehicle and its components.

- Reduced Cargo Damage: Preventing uneven loading and unloading minimizes the risk of cargo damage, leading to cost savings and avoiding potential delays.

- Ease of Use: Modern laser leveling systems are user-friendly and require minimal training.

Details: In construction trucking, laser leveling is vital for accurate placement of materials, ensuring smooth and efficient site preparation. In heavy haul, it's crucial for maintaining stability and preventing rollovers. By using laser-based leveling systems, construction and heavy haul trucking operations can improve efficiency, reduce risks, and ultimately save money.

Conclusion

This Big Rig ROCK Report on Laser 101.7 has demonstrated the significant practical applications of laser technology within the trucking industry. From improving vehicle alignment and enhancing loading efficiency to boosting road safety and optimizing construction operations, laser measurement tools are transforming how trucking businesses operate. By embracing these innovative technologies, trucking companies can achieve significant improvements to their bottom line, enhance safety protocols, and increase overall operational efficiency. Explore the range of laser measurement tools available and discover how you can implement laser technology to optimize your own Big Rig operations. Invest in laser technology today – it's an investment in a safer, more efficient, and more profitable future!

Featured Posts

-

Schwerer Unfall In Stemwede Auto Kracht Gegen Baum

May 23, 2025

Schwerer Unfall In Stemwede Auto Kracht Gegen Baum

May 23, 2025 -

Two Night Metallica Concert In Dublin Aviva Stadium June 2026

May 23, 2025

Two Night Metallica Concert In Dublin Aviva Stadium June 2026

May 23, 2025 -

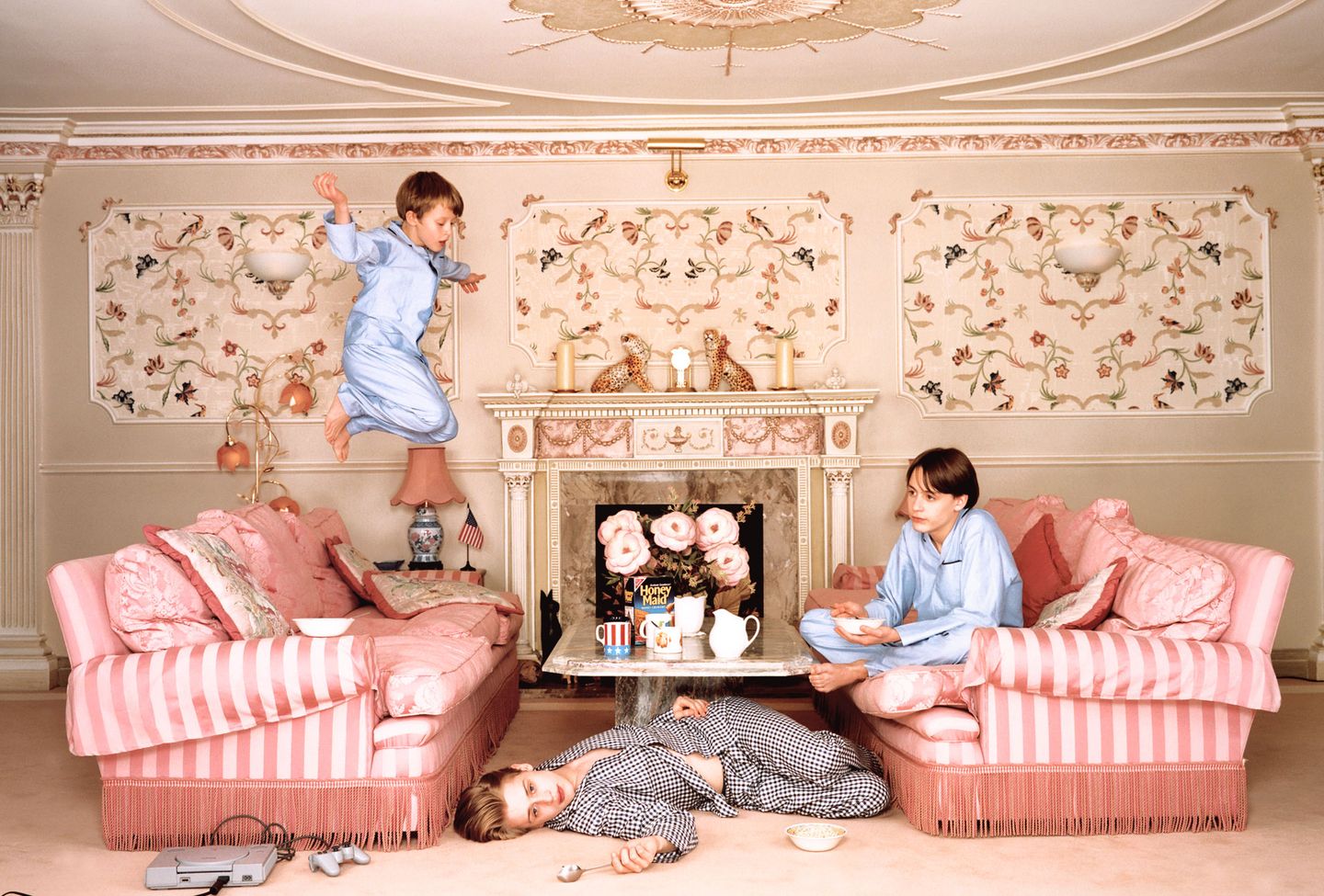

The Culkin Family Ailing Mothers Financial Situation Raises Questions

May 23, 2025

The Culkin Family Ailing Mothers Financial Situation Raises Questions

May 23, 2025 -

Julianne Moores Siren First Trailer Breakdown Dark Comedy Series

May 23, 2025

Julianne Moores Siren First Trailer Breakdown Dark Comedy Series

May 23, 2025 -

Ftc Appeals Activision Blizzard Acquisition Whats Next For Microsoft

May 23, 2025

Ftc Appeals Activision Blizzard Acquisition Whats Next For Microsoft

May 23, 2025