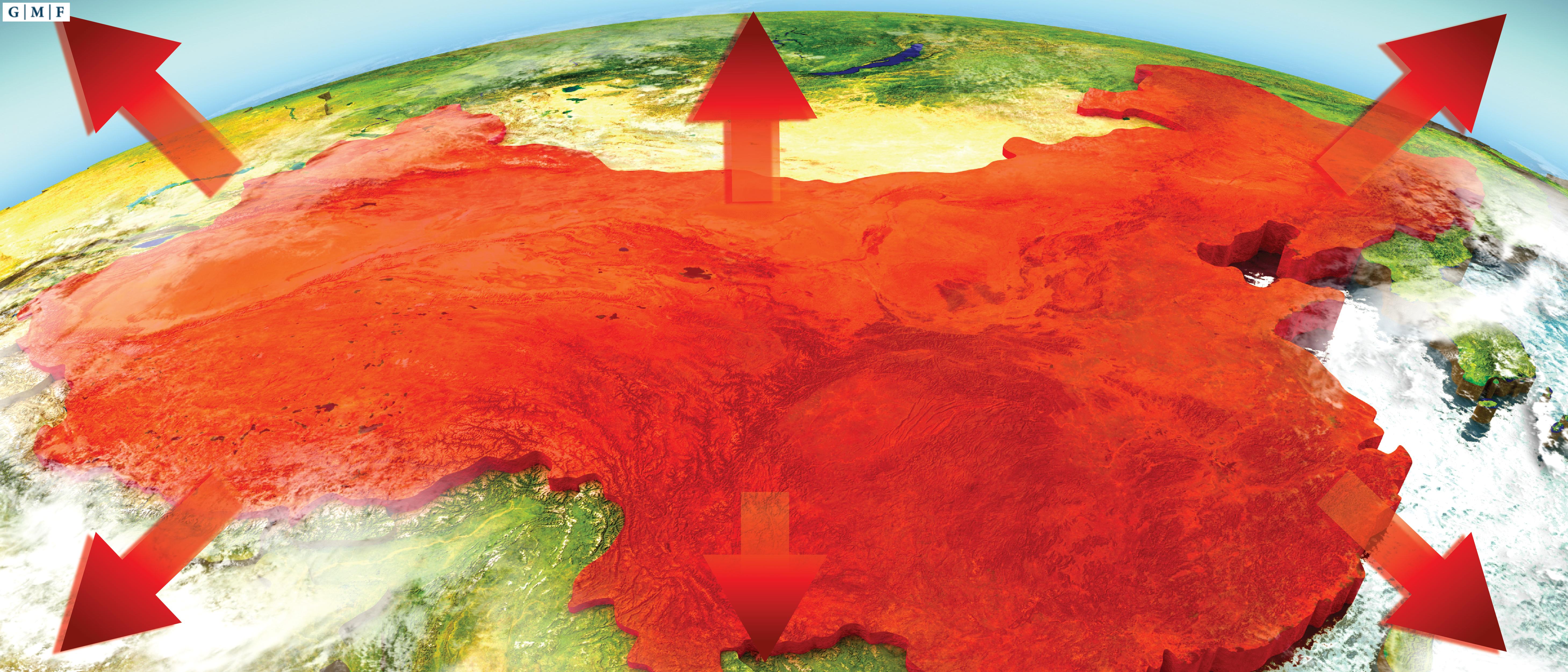

Breaking Free: How Advanced Electric Motors Can End China's Dominance

Table of Contents

Technological Advancements Challenging Chinese Monopoly

The key to breaking China's hold on the electric motor market lies in developing superior technology. Several advancements are paving the way for a more competitive landscape:

Next-Generation Motor Designs

China's dominance is partly due to its control over rare earth minerals, essential for many permanent magnet motors. However, innovative designs are emerging that lessen this dependence:

- Permanent Magnet-less Motors: These motors eliminate the need for rare earth magnets, offering a cost-effective and geopolitically secure alternative. They boast high efficiency and robust performance, making them ideal for various applications.

- Switched Reluctance Motors (SRMs): SRMs are simpler in design, requiring fewer components and reducing manufacturing costs. Their ruggedness and high torque density make them suitable for demanding industrial applications.

- Axial Flux Motors: Offering higher power density in a smaller package, axial flux motors are particularly attractive for electric vehicles and robotics.

Companies like Siemens, Nidec, and various research institutions are actively developing and refining these next-generation motor designs, pushing the boundaries of efficiency and performance.

Improved Power Electronics and Control Systems

Beyond motor design, advancements in power electronics and control systems are crucial. These improvements translate directly into better motor performance and efficiency:

- Silicon Carbide (SiC) Power Modules: SiC offers significantly lower energy losses compared to traditional silicon-based systems, leading to increased efficiency and reduced heat generation.

- Advanced Control Algorithms: Sophisticated algorithms optimize motor operation, maximizing efficiency, torque, and speed control while minimizing energy consumption and extending lifespan.

- Artificial Intelligence (AI)-driven predictive maintenance: AI can analyze motor performance data to predict potential failures, enabling proactive maintenance and reducing downtime.

These advancements are resulting in electric motors with superior performance, lower maintenance costs, and extended operational lifespans, exceeding the capabilities of many current Chinese offerings.

Advanced Manufacturing Techniques

Modern manufacturing techniques are playing a critical role in lowering costs and improving the quality of electric motors:

- Additive Manufacturing (3D Printing): 3D printing allows for the creation of complex motor components with high precision, enabling customization and potentially reducing material waste.

- Advanced Robotics: Automation in motor manufacturing increases production speed, improves consistency, and reduces labor costs, contributing to a more competitive production process.

- Digital Twins and Simulation: Utilizing digital twins for design and testing allows for optimization before physical prototypes are created, saving time and resources.

Companies are increasingly adopting these advanced manufacturing methods to achieve higher precision, faster production cycles, and ultimately, lower manufacturing costs.

Diversifying Supply Chains and Reducing Reliance on China

Breaking China's dominance requires a multifaceted approach to diversifying the global supply chain:

Strategic Partnerships and Investments

International collaboration is key to fostering a robust and resilient electric motor industry. This includes:

- Joint Ventures: Creating joint ventures with companies in countries like the US, Europe, and Japan to share technology and expertise.

- Foreign Direct Investment: Encouraging foreign investment in electric motor manufacturing facilities outside of China to build local capacity.

- Public-Private Partnerships: Collaborative efforts between governments and private companies to accelerate innovation and development.

This strategic approach helps disperse manufacturing capacity and reduces reliance on a single geopolitical entity.

Reshoring and Regionalization of Production

Bringing electric motor production back to domestic markets ("reshoring") or regionalizing it within trusted alliances offers several benefits:

- Reduced Geopolitical Risk: Reshoring reduces dependence on a single supplier, mitigating the risk of supply chain disruptions due to geopolitical instability.

- Enhanced National Security: Domestic production of critical components strengthens national security by reducing reliance on foreign sources.

- Economic Growth and Job Creation: Reshoring and regionalization stimulate domestic economies, creating jobs and boosting local industries.

The economic and security benefits of reshoring and regionalization are compelling arguments for diversification.

Secure Sourcing of Critical Materials

Securing reliable supplies of rare earth minerals and other critical materials is crucial:

- Recycling: Investing in rare earth recycling technologies to recover valuable materials from end-of-life products.

- Alternative Materials: Exploring alternative materials that can replace rare earths in motor designs.

- Strategic Partnerships with Miners: Developing strategic partnerships with mining companies outside of China to secure reliable supplies.

Diversifying the sources of critical materials is vital to ensure the long-term sustainability of the electric motor industry.

Government Policies and Incentives Supporting Advanced Electric Motor Development

Government intervention plays a crucial role in fostering a thriving electric motor sector:

Research and Development Funding

Government funding is essential for driving innovation:

- Targeted Grants: Providing grants to research institutions and companies developing advanced electric motor technologies.

- Public-Private Partnerships: Collaborating with private companies on research and development projects.

- Incentivizing Innovation: Creating incentives for companies to invest in research and development.

Strategic investment in R&D is essential to maintain a technological edge.

Tax Incentives and Subsidies

Tax breaks and subsidies can incentivize domestic manufacturing and adoption:

- Tax Credits for Domestic Production: Offering tax credits to companies that manufacture electric motors domestically.

- Subsidies for Adoption: Providing subsidies to consumers and businesses that adopt advanced electric motors.

- Investment Tax Credits: Offering tax credits for investments in electric motor manufacturing facilities.

Financial incentives can accelerate the transition to advanced motor technology.

Regulatory Frameworks

Supportive regulatory frameworks are equally crucial:

- Industry Standards: Establishing clear industry standards for electric motor performance and safety.

- Interoperability Standards: Ensuring that electric motors are compatible with various systems.

- Environmental Regulations: Promoting environmentally friendly motor designs and manufacturing practices.

Clear regulations promote fair competition and ensure the quality of electric motors.

Conclusion

The dominance of China in the electric motor market presents a significant challenge, but advancements in advanced electric motors, coupled with strategic supply chain diversification and supportive government policies, offer a clear path to breaking free from this dependence. By investing in and adopting these innovative technologies, we can secure a more resilient and sustainable future, free from undue reliance on a single source. Learn more about the exciting advancements in advanced electric motors and how you can contribute to a more balanced global market.

Featured Posts

-

Open Ai Simplifies Voice Assistant Creation 2024 Developer Event Highlights

May 05, 2025

Open Ai Simplifies Voice Assistant Creation 2024 Developer Event Highlights

May 05, 2025 -

Sandhagen Vs Figueiredo Key Moments And Results From Ufc On Espn 67

May 05, 2025

Sandhagen Vs Figueiredo Key Moments And Results From Ufc On Espn 67

May 05, 2025 -

Des Moines Ufc Predictions A Comprehensive Preview And Analysis

May 05, 2025

Des Moines Ufc Predictions A Comprehensive Preview And Analysis

May 05, 2025 -

A Quiet Competition Blake Lively And Anna Kendricks Premiere Style

May 05, 2025

A Quiet Competition Blake Lively And Anna Kendricks Premiere Style

May 05, 2025 -

Lizzos Weight Loss Journey Diet Exercise And Body Positivity

May 05, 2025

Lizzos Weight Loss Journey Diet Exercise And Body Positivity

May 05, 2025