BYD Case Study: Examining Their Leading Position In EV Battery Production

Table of Contents

BYD's Technological Advantage: The Blade Battery and Beyond

BYD's technological prowess is a cornerstone of its success in EV battery production. The company's most significant contribution is undoubtedly the Blade Battery, a game-changer in lithium iron phosphate (LFP) battery technology. This innovation significantly impacts the electric vehicle battery market.

-

Advantages of the Blade Battery: The Blade Battery boasts several key advantages over traditional lithium-ion batteries and even other LFP alternatives:

- High Energy Density: Compared to other LFP batteries, the Blade Battery achieves a higher energy density, translating to a longer driving range for electric vehicles.

- Enhanced Safety: Its unique design minimizes the risk of thermal runaway, a significant safety concern with many battery chemistries. This improved safety profile is crucial for broader EV adoption.

- Cost-Effectiveness: BYD's efficient manufacturing process makes the Blade Battery highly cost-competitive, a key factor in making EVs more affordable.

-

Lithium Iron Phosphate (LFP) Chemistry: The use of LFP chemistry is environmentally friendly, reducing reliance on less sustainable materials like cobalt and nickel found in many competing battery technologies. This aligns with BYD’s commitment to sustainable transportation and renewable energy solutions.

-

Beyond the Blade Battery: BYD is not resting on its laurels. The company continues to invest in research and development, exploring other battery technologies to further enhance energy density, safety, and cost-effectiveness. This continuous innovation ensures BYD maintains its competitive edge in the ever-evolving EV battery market.

-

Blade Battery vs. Competitors:

- Higher energy density than comparable LFP batteries.

- Superior safety profile due to reduced thermal runaway risk.

- More cost-effective manufacturing process leading to lower EV prices.

Vertical Integration: Controlling the Supply Chain for EV Battery Production

BYD's vertical integration strategy is another crucial factor in its success. This comprehensive approach encompasses every stage of EV battery production, from raw material sourcing to final vehicle assembly. This control over the entire supply chain provides several significant advantages in the EV battery market.

-

Control and Efficiency: By controlling every aspect of the production process, BYD can optimize efficiency, reduce costs, and ensure consistent high quality. This vertical integration ensures superior supply chain management.

-

Cost Control and Profitability: This reduces reliance on external suppliers, minimizing costs and mitigating risks associated with supply chain disruptions. The result is increased profitability and competitive pricing in the EV battery market.

-

Scalability and Rapid Growth: This integrated model allows BYD to rapidly scale its production capacity to meet the growing global demand for EV batteries. It fosters innovation and market responsiveness.

-

Key Stages of BYD's Vertically Integrated Process:

- Lithium extraction and processing: Securing raw materials directly enhances cost control and supply chain resilience.

- Battery cell manufacturing: In-house cell production guarantees quality and allows for rapid technological innovation.

- Battery pack assembly: Optimizing pack design and assembly further improves efficiency and reduces costs.

- Integration into BYD vehicles: Seamless integration ensures optimal performance and simplifies the overall manufacturing process.

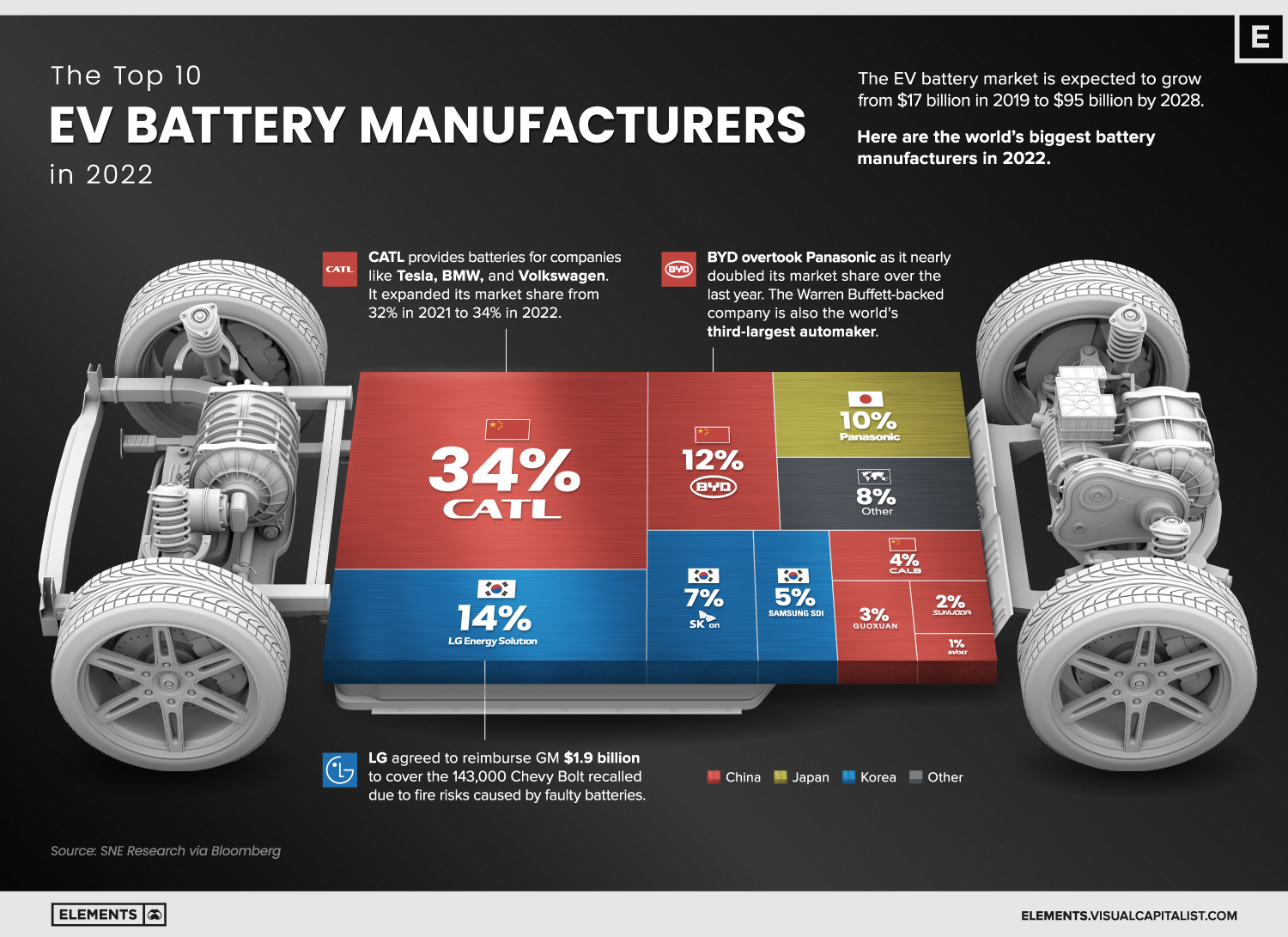

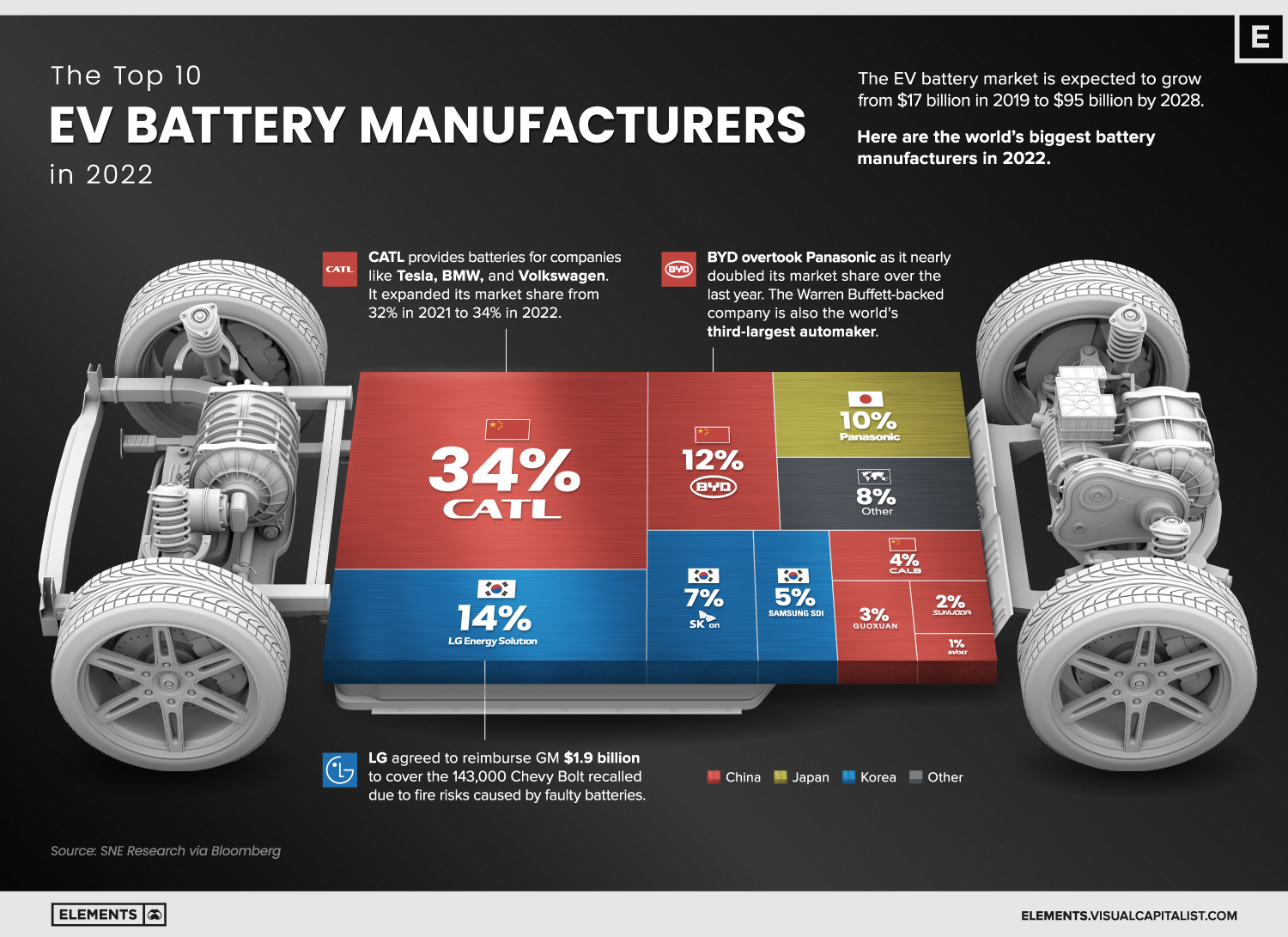

Market Position and Future Outlook for BYD's EV Battery Production

BYD's innovative approach has translated into a significant market presence. The company has secured a substantial share of the global EV battery market and is poised for continued growth.

-

Market Share and Growth: BYD's market share continues to climb, driven by its technological advancements and vertically integrated strategy. The company is a major player, influencing the global EV battery market.

-

Future Growth Projections: The EV battery market is predicted to experience explosive growth in the coming years, and BYD is well-positioned to benefit significantly. Their commitment to renewable energy and sustainable transportation further strengthens their position.

-

Competitive Landscape: While BYD faces competition from established players like CATL and LG Energy Solution, its innovative technologies and vertical integration provide a strong competitive advantage. Their commitment to LFP battery technology provides a unique niche in the EV battery market.

-

Sustainability and Renewable Energy: BYD's commitment to renewable energy sources in its manufacturing process enhances its sustainability credentials, appealing to environmentally conscious consumers and aligning with global sustainability goals.

-

Future Forecast: BYD's future in EV battery production looks bright. We anticipate:

- Continued market share growth fueled by innovation and vertical integration.

- Expansion into new geographical markets to meet growing global demand.

- Potential partnerships and collaborations with other automotive manufacturers.

Conclusion

This case study has highlighted BYD's remarkable success in becoming a global leader in EV battery production. Their innovative Blade Battery technology, coupled with a vertically integrated supply chain, has given them a significant competitive edge in the EV battery market. This strategy has not only boosted their own EV sales but also positions them to play a pivotal role in the global transition to sustainable transportation. The company's focus on renewable energy further cements its position as a leader in this critical sector.

Call to Action: To learn more about the latest advancements in BYD's EV battery production and their impact on the future of electric vehicles, explore their official website and stay informed about the ongoing developments in this rapidly evolving sector of the renewable energy industry. Continue reading more case studies on BYD and other players in the EV battery production market to better understand this critical component of the transition to sustainable mobility. Understanding BYD’s approach to EV battery production is crucial for anyone interested in the future of electric vehicles.

Featured Posts

-

Inside Our Adhd Minds Navigating Daily Life With Attention Deficit Hyperactivity Disorder

May 13, 2025

Inside Our Adhd Minds Navigating Daily Life With Attention Deficit Hyperactivity Disorder

May 13, 2025 -

Dutertes Legacy Analyzing The Results Of The Philippine Midterm Elections

May 13, 2025

Dutertes Legacy Analyzing The Results Of The Philippine Midterm Elections

May 13, 2025 -

Norfolk Catholic Falls Short Against Archbishop Bergan In District Final

May 13, 2025

Norfolk Catholic Falls Short Against Archbishop Bergan In District Final

May 13, 2025 -

Did Leonardo Di Caprio Make A Secret Met Gala Debut With Vittoria Ceretti

May 13, 2025

Did Leonardo Di Caprio Make A Secret Met Gala Debut With Vittoria Ceretti

May 13, 2025 -

Cubs Fans React To Kyle Tucker Report

May 13, 2025

Cubs Fans React To Kyle Tucker Report

May 13, 2025