BYD's EV Battery Dominance: A Case Study Addendum

Table of Contents

1. Vertical Integration: A Key to BYD's Success

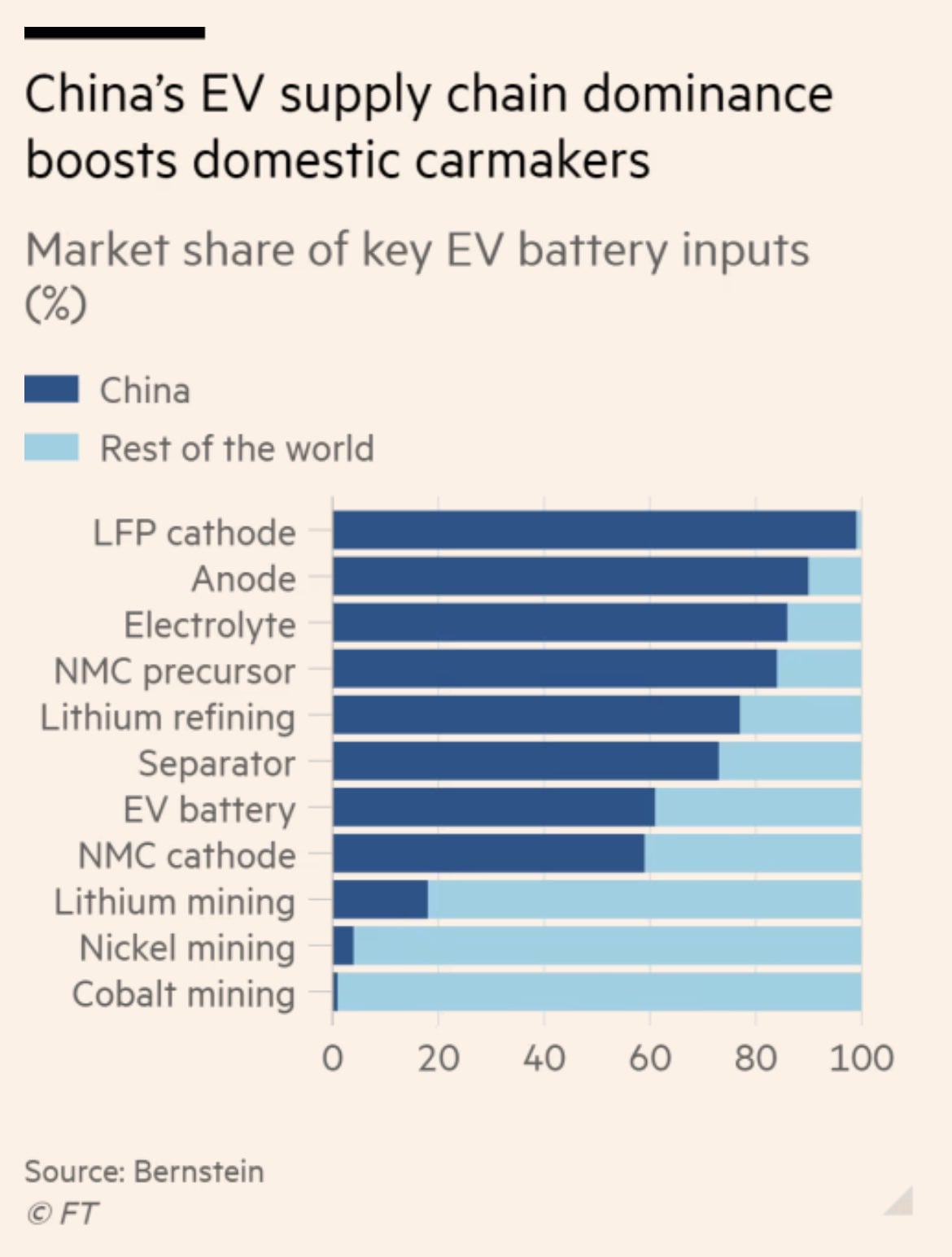

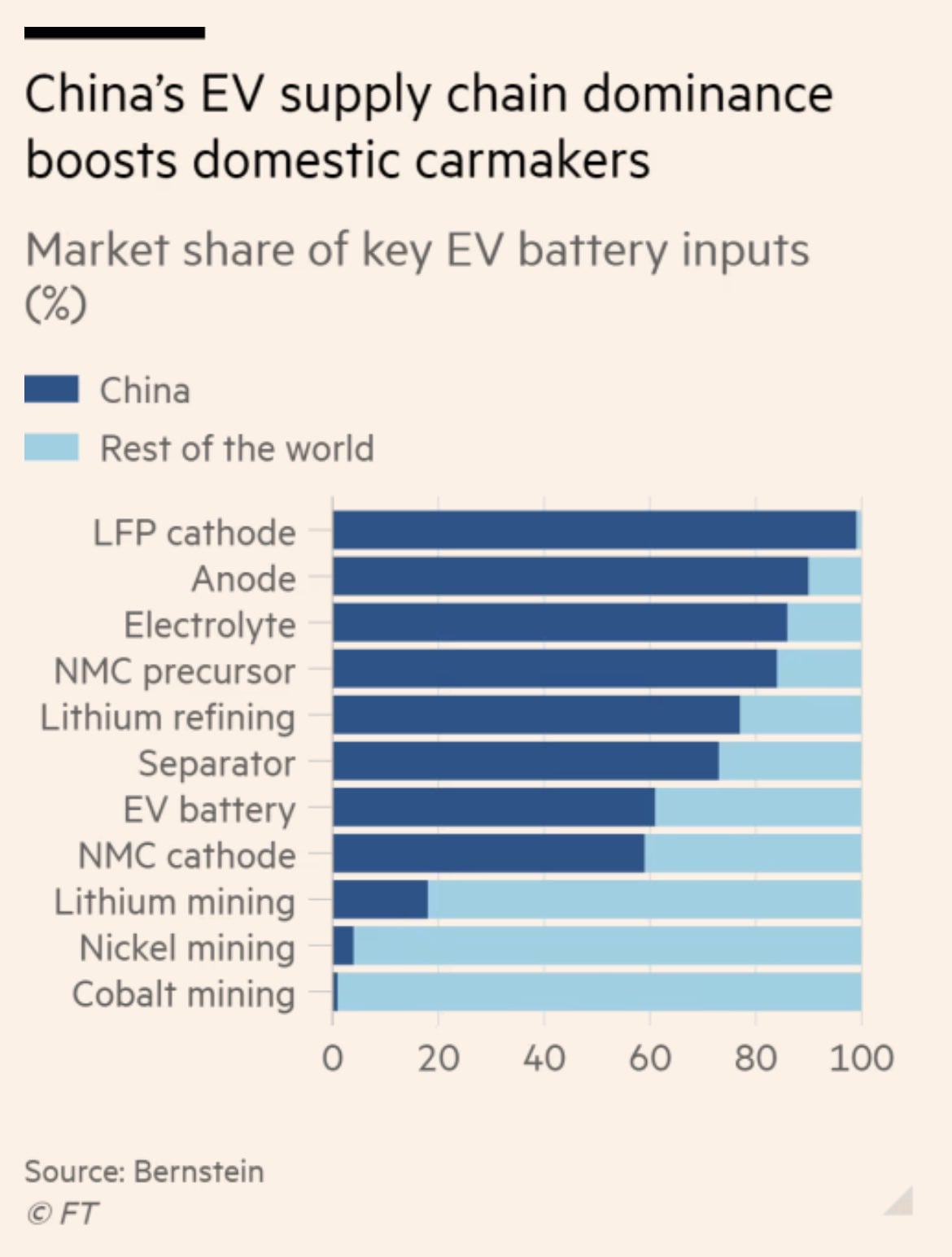

Vertical integration is a crucial element of BYD's success in the competitive EV battery market. Unlike many competitors who rely on external suppliers for various components, BYD controls a significant portion of its supply chain, from raw material sourcing to battery pack assembly. This strategic approach offers several key advantages:

- Reduced Costs: Streamlined processes and in-house production minimize reliance on third-party suppliers, resulting in lower production costs and improved profit margins. This allows BYD to offer competitive pricing in the global EV battery market.

- Improved Quality Control: BYD maintains tight control over quality at every stage of production, ensuring consistent performance and reliability of its batteries. This is vital for building a strong reputation for quality and customer trust.

- Faster Innovation Cycles: Internal control over the entire production process facilitates quicker implementation of new technologies and innovations. This allows BYD to stay ahead of the curve in the rapidly evolving EV battery landscape.

- Reduced Supply Chain Disruptions: By controlling multiple stages of production, BYD is less vulnerable to disruptions caused by external supplier issues, geopolitical instability, or material shortages. This provides greater resilience in a dynamic market.

Examples of BYD's vertical integration include its subsidiaries involved in mining and processing raw materials like lithium and cobalt, manufacturing battery cells and modules, and ultimately assembling battery packs for its own EVs and those of its customers. This comprehensive approach ensures operational efficiency and strategic advantage.

2. Blade Battery Technology: Innovation as a Competitive Advantage

BYD's Blade Battery technology represents a significant leap forward in EV battery design. Unlike traditional cylindrical or prismatic cells, the Blade Battery utilizes a unique cell-to-pack design, resulting in several key advantages:

- Increased Energy Density: The Blade Battery achieves a higher energy density compared to traditional designs, allowing for increased range in electric vehicles without compromising vehicle size or weight.

- Improved Safety: Its unique structure enhances safety by reducing the risk of thermal runaway and improving overall battery stability. This is a significant selling point for consumers concerned about EV safety.

- Space-Saving Design: The flat, blade-like shape of the cells allows for efficient packaging within the vehicle chassis, maximizing interior space and improving vehicle design flexibility.

This innovative technology has significantly contributed to BYD's market leadership by offering superior performance, safety, and cost-effectiveness. The Blade Battery has impacted EV vehicle design, enabling manufacturers to create more spacious and efficient electric cars.

3. Sustainable Practices and Raw Material Sourcing:

BYD is increasingly emphasizing sustainable practices throughout its battery production process. The company is actively working on:

- Responsible Sourcing of Raw Materials: BYD is committed to sourcing raw materials responsibly, minimizing environmental impact and promoting ethical labor practices in its supply chain. This includes tracing the origin of materials to ensure adherence to environmental and social standards.

- Recycling and Waste Reduction: BYD is investing in recycling technologies to recover valuable materials from end-of-life batteries, reducing waste and minimizing the environmental footprint of its operations.

These environmentally conscious practices enhance BYD's brand image, attracting environmentally aware consumers and investors. Sustainable sourcing also contributes to the long-term resilience and growth of the company by securing access to essential raw materials and reducing reliance on potentially unstable or environmentally damaging supply chains.

4. Strategic Partnerships and Global Expansion:

BYD's strategic partnerships and global expansion are vital components of its success. The company collaborates with various automotive manufacturers and technology firms to expand its market reach and access new technologies. These partnerships provide access to new markets and enhance technological advancements. BYD's expansion into international markets, while presenting challenges related to regulations and consumer preferences, is strategically important for sustaining its global leadership. Key regions where BYD is making significant inroads include Europe, North America, and Asia.

5. Conclusion: Securing BYD's Future in EV Battery Dominance

BYD's remarkable success in the EV battery market stems from a combination of factors, including its vertically integrated supply chain, innovative Blade Battery technology, commitment to sustainable practices, and strategic global expansion. The company’s focus on efficiency, innovation, and sustainability positions it well for continued dominance in the industry. To stay informed on the latest advancements in BYD's EV battery dominance, continue exploring the company's innovative technologies and future plans. The future of electric vehicle technology is closely intertwined with BYD's continued success in the EV battery sector.

Featured Posts

-

Online Metadoseis Serie A Epilekste To Kalytero Paroxo

May 13, 2025

Online Metadoseis Serie A Epilekste To Kalytero Paroxo

May 13, 2025 -

Byd Seal A Comprehensive Buyers Guide

May 13, 2025

Byd Seal A Comprehensive Buyers Guide

May 13, 2025 -

2025 Texas Rangers Baseball Your Guide To Game Schedules And Broadcast Details

May 13, 2025

2025 Texas Rangers Baseball Your Guide To Game Schedules And Broadcast Details

May 13, 2025 -

Edan Alexander Missing In Gaza Since October 7th

May 13, 2025

Edan Alexander Missing In Gaza Since October 7th

May 13, 2025 -

Miami Heat Fans Find Solace In Nba Tankathon During The Off Season

May 13, 2025

Miami Heat Fans Find Solace In Nba Tankathon During The Off Season

May 13, 2025