Case Study Addendum: BYD's Leadership In Electric Vehicle Battery Manufacturing

Table of Contents

BYD's Vertical Integration Strategy: A Key to Success

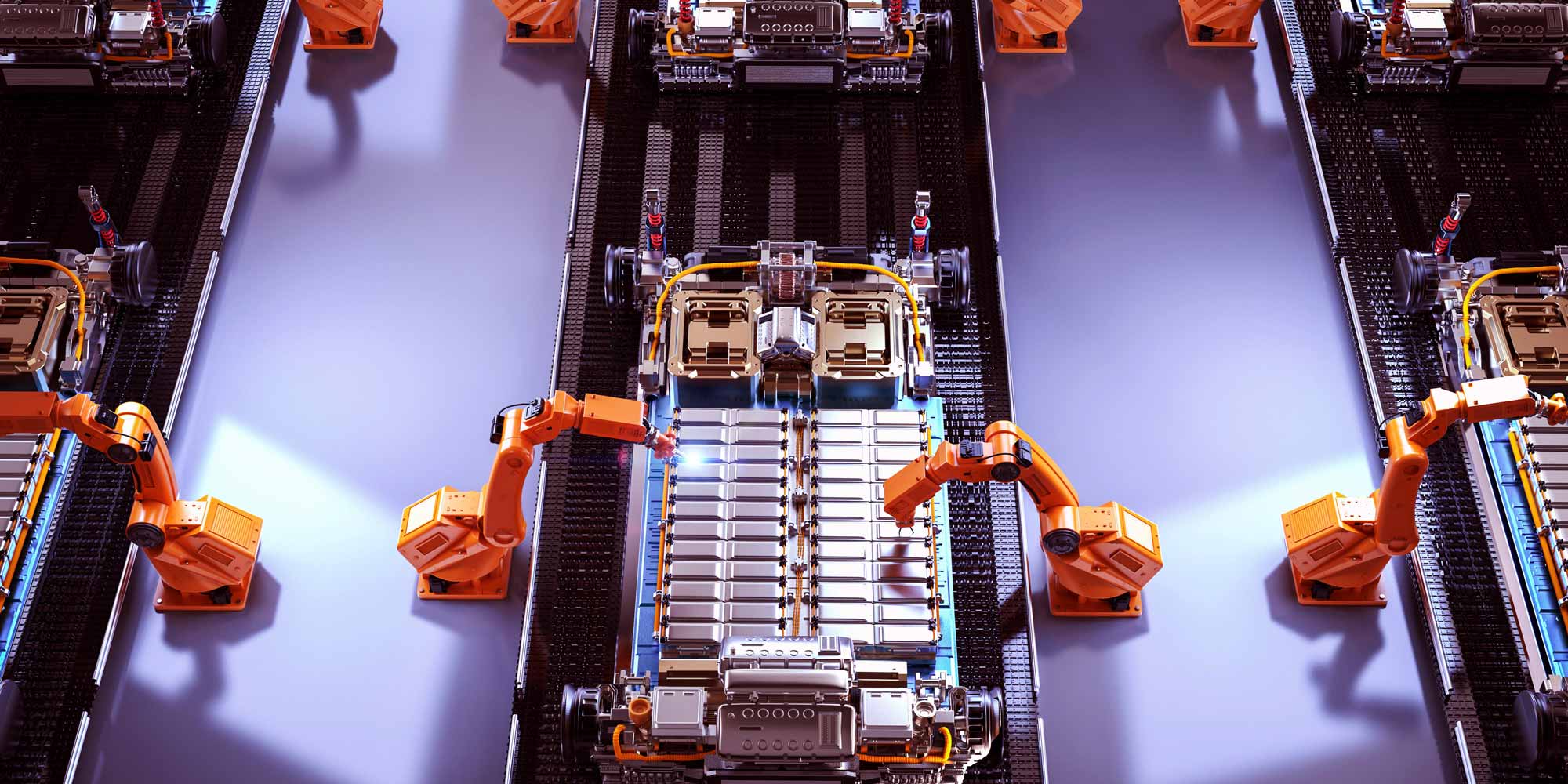

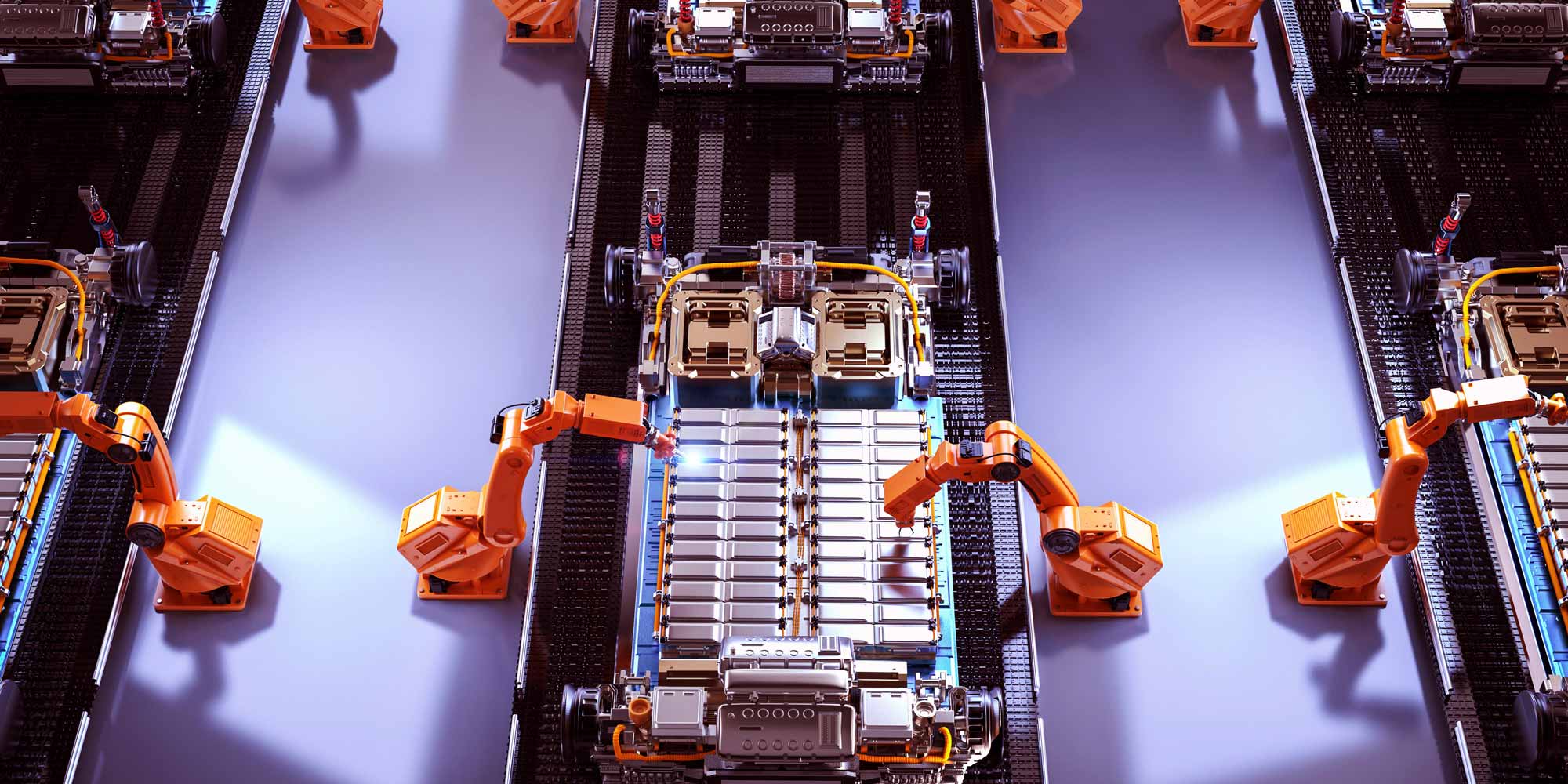

BYD's success in EV battery manufacturing isn't solely attributable to innovative battery technology; a crucial element is its vertically integrated strategy. This approach encompasses complete control over the entire EV battery supply chain, from sourcing raw materials like lithium and cobalt to battery cell production and pack assembly. This vertical integration offers several key advantages:

- Cost Efficiency: Controlling the supply chain minimizes price volatility associated with raw material fluctuations, leading to improved cost efficiency and competitiveness in the EV battery market.

- Enhanced Quality Assurance: Direct oversight at every stage of the manufacturing process ensures superior product reliability and quality control, enhancing the reputation of BYD's EV batteries.

- Faster Innovation Cycles: Streamlined processes within a vertically integrated system allow for quicker implementation of new technologies and faster responses to market demands for improved EV battery performance.

- Scalability and Production Capacity: This integrated model facilitates a rapid scaling of production to meet the exponentially growing global demand for EV batteries, securing BYD's position as a key supplier.

Innovative Battery Technologies: The Blade Battery and Beyond

BYD's pioneering work in Lithium Iron Phosphate (LFP) battery technology, especially its groundbreaking Blade Battery, has significantly impacted the EV industry. LFP batteries offer inherent safety advantages over other chemistries like NMC (Nickel Manganese Cobalt), due to their inherent thermal stability. BYD's Blade Battery further refines this technology:

- Enhanced Safety: LFP's inherent safety features are amplified by the Blade Battery's design, reducing the risk of thermal runaway and improving overall battery safety.

- Increased Energy Density: Despite the advantages in safety, the Blade Battery design cleverly maximizes energy density within a compact form factor, making it suitable for various EV applications.

- Improved Space Utilization: The Blade Battery's unique shape allows for better space utilization in the vehicle, maximizing range and optimizing vehicle design.

- Continuous Technological Innovation: BYD's commitment to ongoing Research and Development (R&D) ensures it remains at the forefront of battery cell technology, constantly striving to improve energy density and cost-effectiveness.

Market Share and Global Expansion: BYD's Growing Influence

BYD's significant market share in the EV battery market is a testament to its successful strategies. The company's global expansion is fueled by several factors:

- Dominant Market Share in Key Regions: BYD boasts a rapidly increasing market share in crucial EV markets, including China and Europe, consistently outpacing many competitors.

- Strategic Partnerships and Collaborations: BYD actively engages in strategic partnerships and collaborations with automakers worldwide, expanding its reach and solidifying its position as a preferred battery supplier.

- Impact on the EV Industry: BYD's innovative battery technologies are reshaping the EV landscape, driving down costs and enhancing performance, making EVs more accessible to a wider market.

- Future Growth Potential: Based on current trends and projected growth in the EV sector, BYD's future market dominance in EV battery production seems assured, given its continuous technological advancements and expansion plans.

Sustainability and Environmental Impact: A Responsible Approach

BYD's commitment extends beyond technological innovation; it includes a strong emphasis on sustainability and environmental responsibility. The company actively pursues:

- Reduced Carbon Footprint: BYD implements initiatives to reduce its carbon footprint throughout the battery manufacturing process, emphasizing energy efficiency and renewable energy sources.

- Responsible Sourcing of Raw Materials: The company focuses on ethical and sustainable sourcing of raw materials, minimizing environmental damage and promoting responsible mining practices.

- Commitment to Environmental Sustainability: BYD's commitment to environmental sustainability is integral to its business strategy, enhancing its brand image and attracting environmentally conscious consumers.

Conclusion:

BYD's leadership in electric vehicle battery manufacturing is undeniable. Its vertically integrated strategy, innovative battery technologies like the Blade Battery, and aggressive global expansion have secured its position as a major player in the EV industry. The company's commitment to sustainable practices further strengthens its role as a responsible leader in the transition towards a cleaner energy future. To delve deeper into the future of EV battery technology and BYD's continued innovations, further research into BYD's electric vehicle battery manufacturing is highly recommended.

Featured Posts

-

How Byd Is Capitalizing On Fords Retreat From The Brazilian Ev Market

May 13, 2025

How Byd Is Capitalizing On Fords Retreat From The Brazilian Ev Market

May 13, 2025 -

New Taverna In Portola Valley A Taste Of Greece

May 13, 2025

New Taverna In Portola Valley A Taste Of Greece

May 13, 2025 -

The Kyle Tucker Report And Its Impact On Cubs Fans

May 13, 2025

The Kyle Tucker Report And Its Impact On Cubs Fans

May 13, 2025 -

Yellowstone Creators Next Hit Demi Moores Drama Gets Season Two Pick Up

May 13, 2025

Yellowstone Creators Next Hit Demi Moores Drama Gets Season Two Pick Up

May 13, 2025 -

Elsbeth Season 2 Episode 16 And 17 Previews And Season Finale Speculation

May 13, 2025

Elsbeth Season 2 Episode 16 And 17 Previews And Season Finale Speculation

May 13, 2025