Cost-Cutting Measures: How U.S. Businesses Respond To Tariff Instability

Table of Contents

Restructuring Supply Chains to Mitigate Tariff Impacts

Tariff instability creates significant uncertainty in global supply chains. One of the most effective cost-cutting measures businesses are employing is a complete restructuring of their sourcing and manufacturing processes.

Sourcing Alternatives

To minimize exposure to fluctuating tariffs, companies are actively diversifying their supply chains. This involves several key strategies:

- Negotiating with existing suppliers for price reductions: Leveraging established relationships to secure better pricing terms and potentially locking in prices for a defined period.

- Exploring domestic sourcing options: Reshoring or nearshoring manufacturing to reduce reliance on imports and minimize tariff exposure. This often involves exploring incentives and support from local governments.

- Diversifying sourcing across multiple countries: Reducing dependence on single-country suppliers to spread risk and mitigate the impact of tariffs imposed on specific nations. This requires careful analysis of alternative supplier capabilities and geopolitical stability.

Keywords: Supply chain diversification, sourcing strategies, offshore sourcing, domestic sourcing, supplier negotiation, tariff mitigation.

Nearshoring and Reshoring

Bringing manufacturing closer to home—nearshoring (to nearby countries) or reshoring (back to the U.S.)—is gaining momentum. While this can increase initial costs, it offers long-term benefits:

- Advantages: Reduced transportation costs, shorter lead times, greater control over quality and production processes, and reduced exposure to tariff fluctuations.

- Disadvantages: Higher labor costs in some regions, potential challenges in finding skilled labor, and increased logistical complexities.

- Government Incentives: Many governments offer incentives, such as tax breaks and grants, to encourage reshoring and nearshoring initiatives. Thorough research into these available programs is crucial for cost-effective implementation.

Keywords: Nearshoring, reshoring, onshoring, manufacturing relocation, logistics optimization, government incentives.

Implementing Lean Manufacturing and Operational Efficiency

Beyond supply chain adjustments, many companies are focusing on internal operational efficiency as a key cost-cutting measure.

Streamlining Processes

Lean manufacturing principles are essential in optimizing workflows and eliminating waste. This includes:

- Lean manufacturing principles: Implementing methodologies like Kaizen (continuous improvement) and Six Sigma to identify and eliminate inefficiencies in production processes.

- Automation: Automating repetitive tasks to increase productivity, reduce labor costs, and minimize errors.

- Process optimization: Analyzing workflows to identify bottlenecks and improve overall efficiency through process redesign and technological upgrades.

- Waste reduction strategies: Focusing on minimizing waste in materials, time, and resources through careful planning and execution.

Keywords: Lean manufacturing, process improvement, automation technology, operational efficiency, waste management, cost reduction.

Inventory Management

Efficient inventory management is crucial for minimizing the financial impact of tariff instability:

- Just-in-time inventory: Minimizing inventory levels to reduce storage costs and the risk of obsolescence due to tariff changes.

- Inventory forecasting: Using data-driven models to accurately predict demand and optimize inventory levels.

- Supply chain visibility: Implementing systems to track inventory levels and monitor supplier performance in real-time.

- Risk management: Developing contingency plans to mitigate the impact of unexpected tariff increases or supply chain disruptions.

Keywords: Inventory management, just-in-time inventory, supply chain visibility, inventory optimization, risk mitigation, tariff impact.

Reducing Labor Costs and Optimizing Workforce

While a difficult decision, workforce optimization is another critical cost-cutting measure for some businesses facing tariff pressures.

Automation and Technology

Technology plays a significant role in reducing labor costs:

- Robotics: Implementing robotic automation for repetitive and labor-intensive tasks.

- AI: Utilizing artificial intelligence for process optimization, predictive maintenance, and improved decision-making.

- Automation software: Streamlining various business processes through automated workflows and data analysis.

- Impact on employment: While automation can lead to job displacement in some areas, it also creates new opportunities in technology and management roles. Careful planning and retraining initiatives are crucial to mitigate negative consequences.

Keywords: Automation, robotics, AI in manufacturing, workforce optimization, technological advancements, cost reduction strategies.

Restructuring and Downsizing

In some cases, restructuring and workforce reduction may be necessary:

- Ethical considerations: Downsizing must be approached ethically and transparently, providing support and resources to affected employees.

- Employee retention strategies: Implementing measures to retain key employees and minimize turnover.

- Government assistance programs: Exploring government programs designed to support workers affected by job losses.

Keywords: Workforce reduction, downsizing, employee retention, restructuring, cost optimization, ethical considerations.

Seeking Government Assistance and Financial Strategies

U.S. businesses can leverage government resources and strategic financial planning as cost-cutting measures.

Tariff Relief Programs

Several government programs offer support to businesses affected by tariffs:

- Specific programs: Research programs like the Trade Adjustment Assistance (TAA) program and other industry-specific initiatives.

- Eligibility requirements: Understanding the criteria for eligibility and the application process for each program.

Keywords: Tariff relief, government assistance, financial aid, business subsidies, economic stimulus, TAA.

Financial Strategies

Proactive financial planning is crucial:

- Cost analysis: Conducting thorough cost analysis to identify areas for cost reduction.

- Budget reallocation: Reallocating resources to prioritize essential operations and investments.

- Securing loans: Exploring options for securing loans or lines of credit to bridge short-term financial gaps.

- Investment strategies: Investing in technologies and processes that improve efficiency and reduce long-term costs.

Keywords: Financial planning, budgeting, cost analysis, investment strategies, loan applications, financial management.

Conclusion: Navigating Tariff Instability with Effective Cost-Cutting Measures

This article has explored several key cost-cutting measures U.S. businesses are employing to navigate the challenges of tariff instability. From restructuring supply chains and implementing lean manufacturing principles to leveraging technology and seeking government assistance, proactive adaptation is essential. Effective cost-cutting measures require strategic planning, careful analysis, and a commitment to operational efficiency. The key takeaway is the importance of flexibility and adaptability in responding to unpredictable economic conditions. Don't let tariff instability cripple your business. Implement effective cost-cutting measures and develop robust strategies today to secure your future and mitigate the impact of future tariff fluctuations. By proactively addressing these challenges, U.S. businesses can enhance their resilience and maintain competitiveness in the global market.

Featured Posts

-

Europe On High Alert Analyzing Recent Russian Military Actions

Apr 29, 2025

Europe On High Alert Analyzing Recent Russian Military Actions

Apr 29, 2025 -

I M Staying Put Schumer Defends Leadership Amid Calls For Change

Apr 29, 2025

I M Staying Put Schumer Defends Leadership Amid Calls For Change

Apr 29, 2025 -

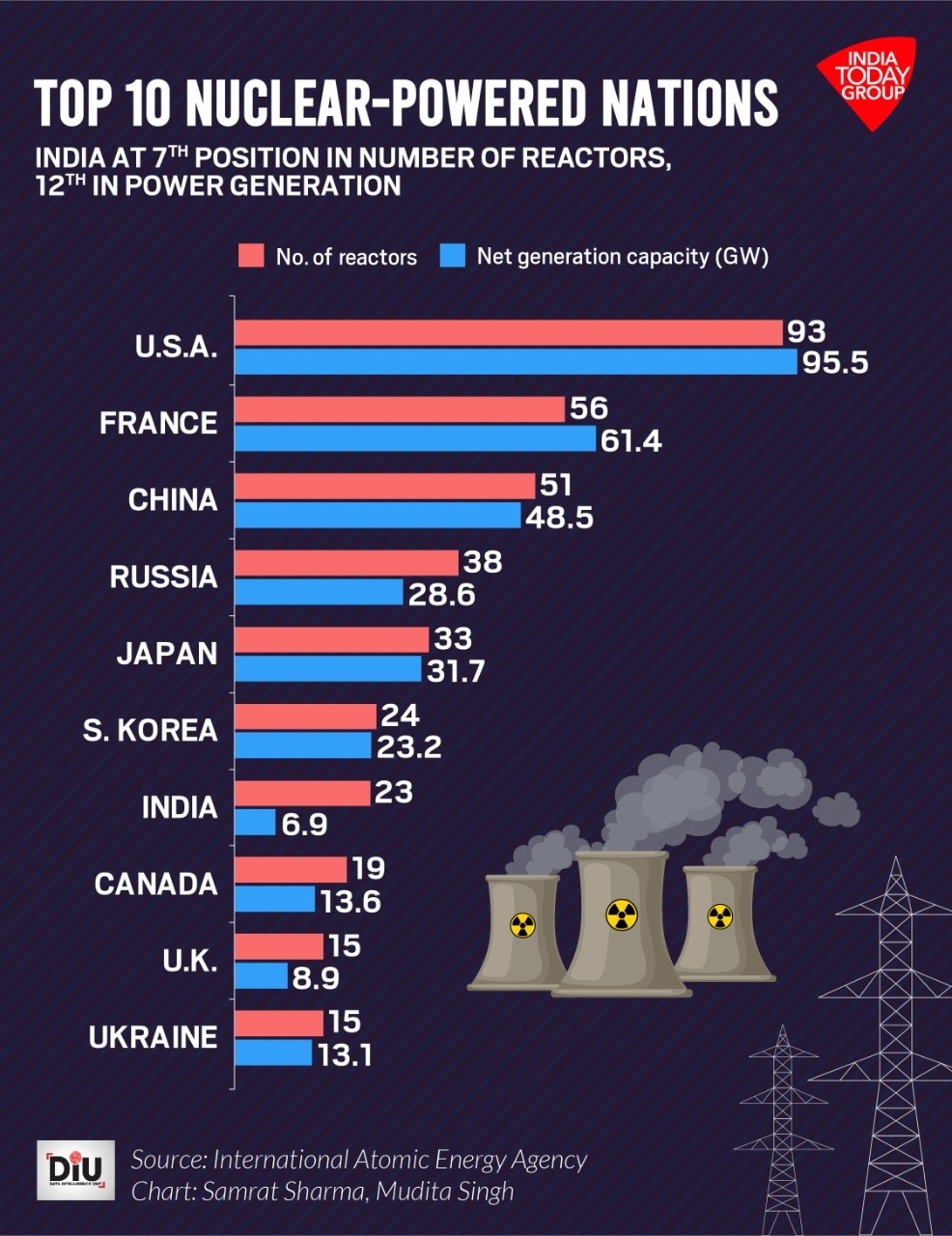

Chinas Nuclear Power Expansion 10 New Reactors Approved

Apr 29, 2025

Chinas Nuclear Power Expansion 10 New Reactors Approved

Apr 29, 2025 -

Blue Origin Rocket Launch Aborted Subsystem Malfunction Reported

Apr 29, 2025

Blue Origin Rocket Launch Aborted Subsystem Malfunction Reported

Apr 29, 2025 -

The Crucial Role Of Middle Managers In Employee Development And Company Growth

Apr 29, 2025

The Crucial Role Of Middle Managers In Employee Development And Company Growth

Apr 29, 2025

Latest Posts

-

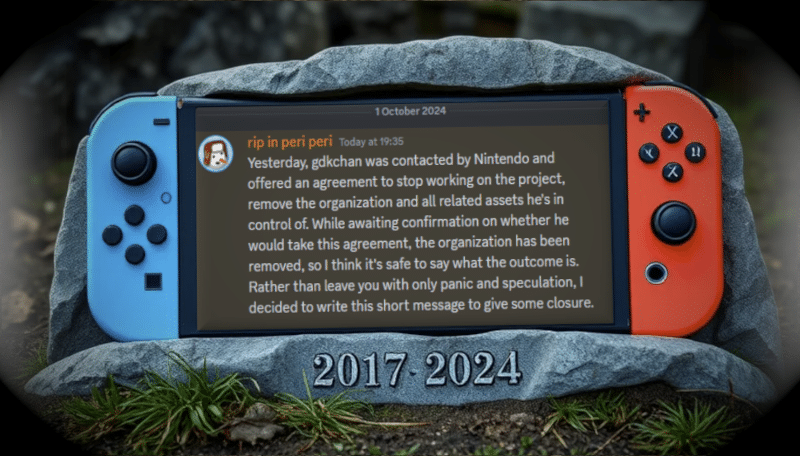

The End Of Ryujinx A Nintendo Related Shutdown

Apr 29, 2025

The End Of Ryujinx A Nintendo Related Shutdown

Apr 29, 2025 -

Ryujinx Emulator Project Ends After Alleged Nintendo Intervention

Apr 29, 2025

Ryujinx Emulator Project Ends After Alleged Nintendo Intervention

Apr 29, 2025 -

Confronting Google Perplexity Ceos Perspective On The Emerging Ai Browser Market

Apr 29, 2025

Confronting Google Perplexity Ceos Perspective On The Emerging Ai Browser Market

Apr 29, 2025 -

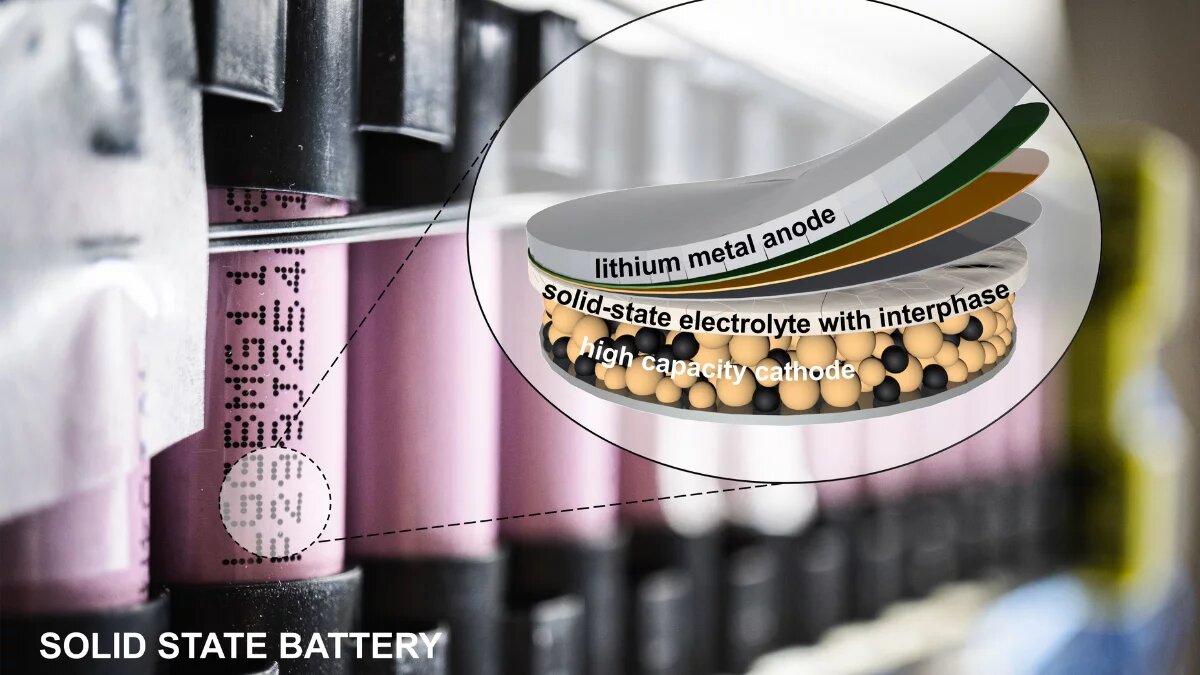

Kuxius Revolutionary Solid State Power Bank Durability And Performance Compared

Apr 29, 2025

Kuxius Revolutionary Solid State Power Bank Durability And Performance Compared

Apr 29, 2025 -

The Future Of Search Perplexitys Ceo On Battling Google In The Ai Browser Race

Apr 29, 2025

The Future Of Search Perplexitys Ceo On Battling Google In The Ai Browser Race

Apr 29, 2025