Cybersecurity Investment: 63.5% Of Manufacturers Prioritize Strengthening Posture

Table of Contents

The Growing Threat Landscape for Manufacturers

The manufacturing sector faces a rapidly evolving and increasingly dangerous threat landscape. Several factors contribute to this heightened risk:

Increased Connectivity and IoT Devices

The widespread adoption of connected devices and the Internet of Things (IoT) in manufacturing environments introduces significant vulnerabilities. This interconnectedness, while offering operational advantages, creates numerous entry points for cyberattacks.

- Vulnerable IoT Devices: Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition (SCADA) systems, and other industrial control systems are often poorly secured, creating opportunities for attackers to disrupt operations or steal data.

- Unpatched Software: Outdated software and firmware on these devices represent significant security risks, leaving manufacturers susceptible to known exploits.

- Data Breaches: Compromised IoT devices can lead to data breaches, exposing sensitive intellectual property, customer information, and operational data. This can result in significant financial losses and reputational damage. Effective manufacturing cybersecurity requires a comprehensive approach to securing these devices. This includes regular patching, robust access controls, and strong network segmentation. Ignoring Industrial IoT security leaves manufacturers vulnerable to crippling attacks. Building a secure smart factory security strategy is paramount.

Sophisticated Cyberattacks

Manufacturers are increasingly targeted by sophisticated cyberattacks designed to disrupt operations, steal data, or extort money.

- Ransomware Attacks: These attacks encrypt critical data, rendering systems unusable until a ransom is paid. The recovery process can be lengthy and costly, disrupting production and causing significant financial losses.

- Supply Chain Attacks: Attackers target manufacturers' suppliers to gain access to their systems. This indirect approach can bypass traditional security measures.

- Espionage: Competitors and state-sponsored actors may target manufacturers to steal valuable intellectual property or sensitive business information. The consequences of such attacks can be devastating and far-reaching. Robust ransomware protection and supply chain security measures are crucial for mitigating these risks. Understanding the nature of manufacturing cyber threats is the first step in effective defense.

Regulatory Compliance and Data Privacy

Manufacturers are subject to various regulations designed to protect sensitive data and ensure cybersecurity best practices. Failure to comply can result in severe penalties.

- NIST Cybersecurity Framework: This framework provides a voluntary set of guidelines for improving cybersecurity practices.

- GDPR (General Data Protection Regulation): This regulation applies to organizations processing personal data of EU residents and mandates strict data protection measures. Non-compliance can lead to hefty fines.

- Industry-Specific Regulations: Other regulations may apply depending on the specific industry and location. Understanding and adhering to these regulations is critical to avoiding legal and financial repercussions. Effective data breach prevention is not just a best practice, but often a legal requirement. Meeting cybersecurity compliance standards is essential for maintaining a strong reputation and avoiding the significant costs associated with GDPR for manufacturers.

Key Areas of Cybersecurity Investment

Manufacturers are investing heavily in several key areas to strengthen their cybersecurity posture:

Network Security

Investing in robust network security infrastructure is fundamental.

- Firewalls: These are essential for controlling network traffic and preventing unauthorized access.

- Intrusion Detection/Prevention Systems (IDS/IPS): These systems monitor network traffic for malicious activity and can automatically block threats.

- Secure Access Controls: These limit access to sensitive systems and data based on user roles and permissions. Regular security audits ensure that these systems are functioning correctly and are up-to-date. Establishing a solid network security for manufacturing strategy is a crucial investment. Selecting appropriate firewall solutions and implementing reliable intrusion detection systems are paramount.

Endpoint Security

Securing individual devices is crucial.

- Endpoint Detection and Response (EDR): EDR solutions provide advanced threat detection and response capabilities for endpoints.

- Patching and Software Updates: Regularly updating software and firmware is crucial to mitigating known vulnerabilities.

- User Training: Educating employees about cybersecurity best practices is vital in preventing human error-related breaches. Investing in effective endpoint security solutions, including EDR, and implementing a robust vulnerability management program are crucial components of a strong cybersecurity strategy.

Security Awareness Training

Employee training is a critical component of a robust cybersecurity strategy.

- Regular Training Programs: These should cover topics such as phishing awareness, password security, and social engineering tactics.

- Phishing Simulations: These help employees identify and report phishing attempts. Effective cybersecurity awareness training, including phishing prevention techniques, is essential. Tailoring security training for manufacturing environments ensures that employees understand the specific risks they face.

Incident Response Planning

Having a well-defined incident response plan is vital.

- Incident Response Team: Designate a team responsible for handling security incidents.

- Regular Testing and Drills: Regularly test and refine the incident response plan to ensure its effectiveness. A comprehensive incident response plan is critical for minimizing the impact of a cyberattack. Effective cybersecurity incident management and robust disaster recovery planning are essential for business continuity.

The Return on Investment (ROI) of Cybersecurity

Proactive cybersecurity investment offers a significant return on investment.

- Reduced Risk of Data Breaches: Strong cybersecurity measures minimize the likelihood of data breaches, saving significant costs associated with legal fees, fines, and reputational damage.

- Improved Operational Efficiency: Reduced downtime and improved system reliability lead to greater operational efficiency.

- Enhanced Brand Reputation: Demonstrating a commitment to cybersecurity builds customer trust and enhances brand reputation.

- Increased Customer Trust: Customers are more likely to do business with organizations that prioritize data security. Calculating the cybersecurity ROI and understanding the true cost of cyberattacks helps justify the necessary investments. Effective risk mitigation strategies protect the bottom line and ensure long-term business viability.

Conclusion

The growing threat landscape necessitates a proactive approach to cybersecurity. The 63.5% of manufacturers prioritizing cybersecurity investment understand this critical need. By investing in network security, endpoint protection, employee training, and incident response planning, manufacturers can significantly reduce their risk of cyberattacks. Don't wait until it's too late. Prioritize your cybersecurity investment today and safeguard your manufacturing operations against the growing threat landscape. Investing in strong cybersecurity is not just an expense; it's a strategic investment that protects your business, your data, and your reputation. Regularly review and update your cybersecurity investment strategy to ensure it remains effective against the ever-evolving threat landscape.

Featured Posts

-

Nova Zbirka Romski Ba Ki E Dostapna

May 13, 2025

Nova Zbirka Romski Ba Ki E Dostapna

May 13, 2025 -

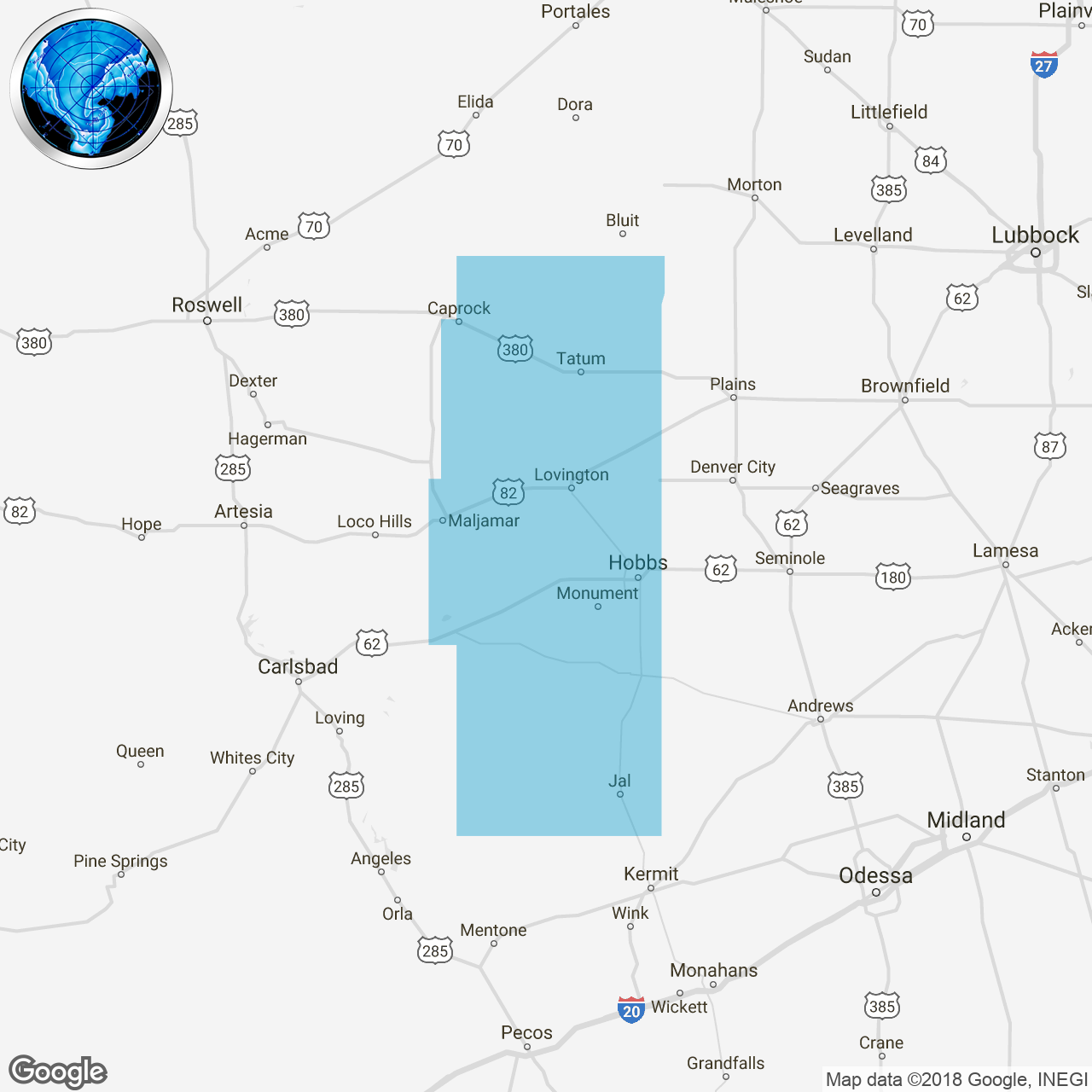

Heat Advisory Issued For Paso Robles How Hot Will It Get

May 13, 2025

Heat Advisory Issued For Paso Robles How Hot Will It Get

May 13, 2025 -

Renowned Golden Horse Awards Cinematographer Lin Tsan Ting Dead At 94

May 13, 2025

Renowned Golden Horse Awards Cinematographer Lin Tsan Ting Dead At 94

May 13, 2025 -

Angel Has Fallen The Impact Of Gerard Butlers Performance

May 13, 2025

Angel Has Fallen The Impact Of Gerard Butlers Performance

May 13, 2025 -

Bar Roma Toronto Blog Tos Take On The Citys Italian Inspired Bar

May 13, 2025

Bar Roma Toronto Blog Tos Take On The Citys Italian Inspired Bar

May 13, 2025