Dysprosium's Critical Role In Electric Vehicle Motors And Its Supply Chain Challenges

Table of Contents

Dysprosium's Importance in Electric Vehicle Motors

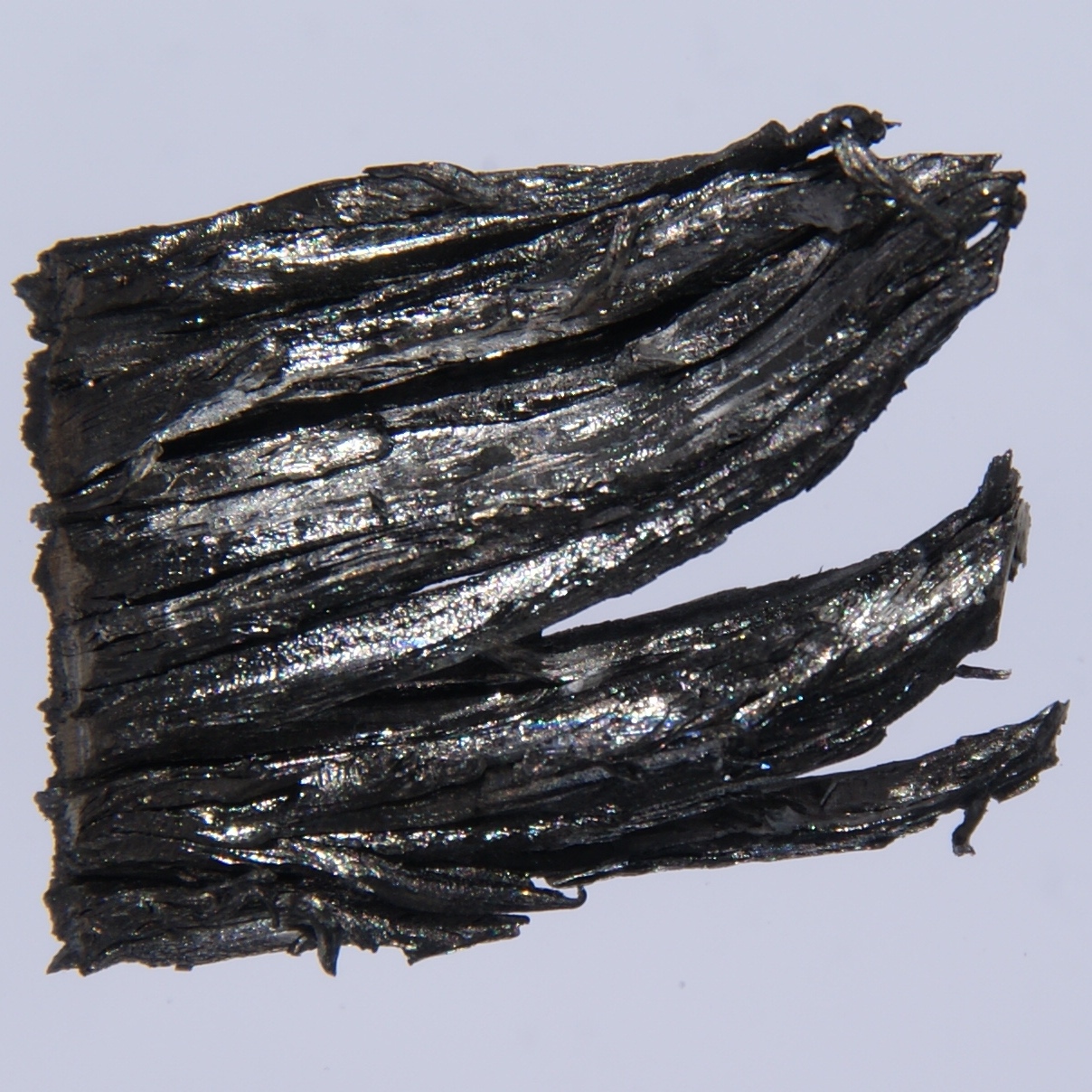

Dysprosium's unique magnetic properties make it indispensable for high-performance neodymium magnets used in EV motors. These magnets offer high power density and efficiency, crucial for maximizing EV range and performance. Without sufficient dysprosium, the performance and capabilities of electric vehicles would be severely limited.

-

Enhances the magnetic strength and thermal stability of neodymium magnets: Dysprosium's addition significantly improves the magnet's resistance to demagnetization at high temperatures, ensuring consistent motor performance even under demanding operating conditions. This is especially critical for EVs operating in diverse climates.

-

Reduces motor size and weight while maintaining high torque output: The superior magnetic properties of dysprosium-enhanced neodymium magnets allow for smaller and lighter motor designs without compromising torque, contributing to improved vehicle efficiency and overall performance.

-

Contributes to improved energy efficiency, extending EV driving range: More efficient motors translate directly to increased driving range on a single charge, a key selling point for electric vehicles. Dysprosium's role in this efficiency gain is paramount.

-

Essential for the performance of both traction motors and auxiliary systems: Dysprosium-based magnets are not only crucial for the primary traction motors that propel the vehicle but are also used in various auxiliary systems, such as power steering and air conditioning compressors.

The Global Dysprosium Supply Chain: A Geopolitical Landscape

The majority of dysprosium production is concentrated in a few countries, creating vulnerabilities in the global supply chain and raising concerns about price volatility and geopolitical risks. This dependence poses a significant threat to the long-term viability of the EV industry.

-

China dominates the global dysprosium mining and processing market: China controls a disproportionately large share of the dysprosium supply, giving it considerable leverage over the global market and raising concerns about potential supply disruptions.

-

Limited diversification of dysprosium sources increases dependency and vulnerability to disruptions: The lack of significant dysprosium production in other countries makes the global supply chain highly susceptible to geopolitical instability, trade disputes, or natural disasters affecting China's mining operations.

-

Geopolitical tensions and trade disputes can significantly impact dysprosium availability and pricing: International relations directly impact dysprosium availability and pricing, creating uncertainty for EV manufacturers and potentially hindering the widespread adoption of electric vehicles.

-

Environmental concerns related to dysprosium mining and processing add to the complexity: The mining and processing of dysprosium can have significant environmental impacts, raising concerns about sustainability and the need for environmentally responsible sourcing practices.

Supply Chain Risks and Mitigation Strategies

The current dysprosium supply chain is prone to disruptions caused by various factors, necessitating proactive mitigation strategies to secure future supplies. Understanding and addressing these risks is essential for the future of the EV industry.

-

Price volatility due to limited supply and fluctuating demand: The imbalance between supply and demand leads to significant price fluctuations, making it difficult for EV manufacturers to accurately forecast costs and plan for production.

-

Risk of supply disruptions due to geopolitical instability or natural disasters: Geopolitical events and natural disasters can severely impact dysprosium production, creating supply shortages and potentially halting EV manufacturing.

-

Ethical sourcing concerns related to mining practices in some regions: Concerns exist regarding the ethical and environmental implications of dysprosium mining in certain regions, requiring the industry to prioritize responsible sourcing practices.

-

Mitigation strategies include exploring alternative magnet materials, improving recycling technologies, and diversifying sourcing locations: Several strategies are being pursued to reduce reliance on dysprosium, including research into alternative magnet materials, advancements in recycling technologies, and the development of new mining operations in diverse locations.

Exploring Alternatives and Sustainable Practices

Research and development efforts are focusing on reducing reliance on dysprosium through the exploration of alternative materials and sustainable practices. This multi-pronged approach is crucial for ensuring the long-term sustainability of the EV industry.

-

Development of dysprosium-reduced or dysprosium-free magnets: Scientists are actively researching and developing new magnet materials that require less dysprosium or eliminate the need for it altogether.

-

Improving the recycling and reuse of neodymium magnets containing dysprosium: Efficient recycling processes are essential for recovering and reusing dysprosium from end-of-life EV components, reducing reliance on primary mining.

-

Implementing sustainable mining practices to minimize environmental impact: Adopting sustainable mining techniques is crucial for minimizing the environmental footprint of dysprosium extraction.

-

Investing in research and exploration of new dysprosium deposits: Investing in exploration activities to discover new dysprosium deposits will help diversify supply sources and reduce reliance on existing, potentially unstable, sources.

Conclusion

Dysprosium plays a critical role in the performance and efficiency of electric vehicle motors, but the challenges associated with its supply chain cannot be ignored. The concentration of production in a few countries, coupled with environmental concerns, necessitates a proactive approach. Diversification of supply sources, investment in alternative materials, and the development of sustainable mining and recycling practices are crucial steps towards ensuring a secure and reliable supply of dysprosium for the future of electric vehicles. Understanding the complexities of the dysprosium supply chain is essential for navigating the path towards a sustainable and widespread adoption of electric vehicle technology. Learn more about securing the future of electric mobility by researching advancements in dysprosium sourcing and alternative magnet technologies.

Featured Posts

-

Understanding Russias Military Strategy And Its Impact On Europe

Apr 29, 2025

Understanding Russias Military Strategy And Its Impact On Europe

Apr 29, 2025 -

Is Kevin Bacon Returning For Tremor 2 On Netflix

Apr 29, 2025

Is Kevin Bacon Returning For Tremor 2 On Netflix

Apr 29, 2025 -

Solve The Nyt Spelling Bee February 12 2025 Hints And Solutions

Apr 29, 2025

Solve The Nyt Spelling Bee February 12 2025 Hints And Solutions

Apr 29, 2025 -

Oh What A Beautiful World A Review Of Willie Nelsons New Album

Apr 29, 2025

Oh What A Beautiful World A Review Of Willie Nelsons New Album

Apr 29, 2025 -

Nyt Spelling Bee February 26th 360 Answers And Helpful Hints

Apr 29, 2025

Nyt Spelling Bee February 26th 360 Answers And Helpful Hints

Apr 29, 2025

Latest Posts

-

Regionalliga Mitte Dsv Leoben Stellt Neues Trainerteam Vor

Apr 29, 2025

Regionalliga Mitte Dsv Leoben Stellt Neues Trainerteam Vor

Apr 29, 2025 -

Porsches International Success An Australian Perspective

Apr 29, 2025

Porsches International Success An Australian Perspective

Apr 29, 2025 -

A Comparative Analysis Of Porsches Market Performance Australia Vs The Rest Of The World

Apr 29, 2025

A Comparative Analysis Of Porsches Market Performance Australia Vs The Rest Of The World

Apr 29, 2025 -

Offiziell Carsten Jancker Ist Neuer Trainer Von Austria Klagenfurt

Apr 29, 2025

Offiziell Carsten Jancker Ist Neuer Trainer Von Austria Klagenfurt

Apr 29, 2025 -

Porsche 911 S T Riviera Blue Pts Buy Now

Apr 29, 2025

Porsche 911 S T Riviera Blue Pts Buy Now

Apr 29, 2025