Exploring Adidas' 3D-Printed Sneaker Technology

Table of Contents

The Advantages of Adidas' 3D-Printed Sneaker Technology

Adidas' foray into 3D-printed sneakers offers a multitude of advantages over traditional manufacturing methods. The benefits extend across sustainability, customization, performance, and efficiency.

-

Sustainability: 3D printing significantly reduces material waste. Traditional shoe manufacturing generates considerable scrap, but with additive manufacturing, Adidas only uses the necessary material, leading to a smaller environmental footprint. This aligns perfectly with Adidas' increasing commitment to sustainable footwear production.

-

Customization: One of the most exciting aspects of 3D-printed sneakers is the unparalleled level of customization. Adidas' technology enables the creation of shoes perfectly tailored to individual foot shapes and preferences. This means enhanced comfort and a truly personalized fit, unlike anything previously available on a large scale.

-

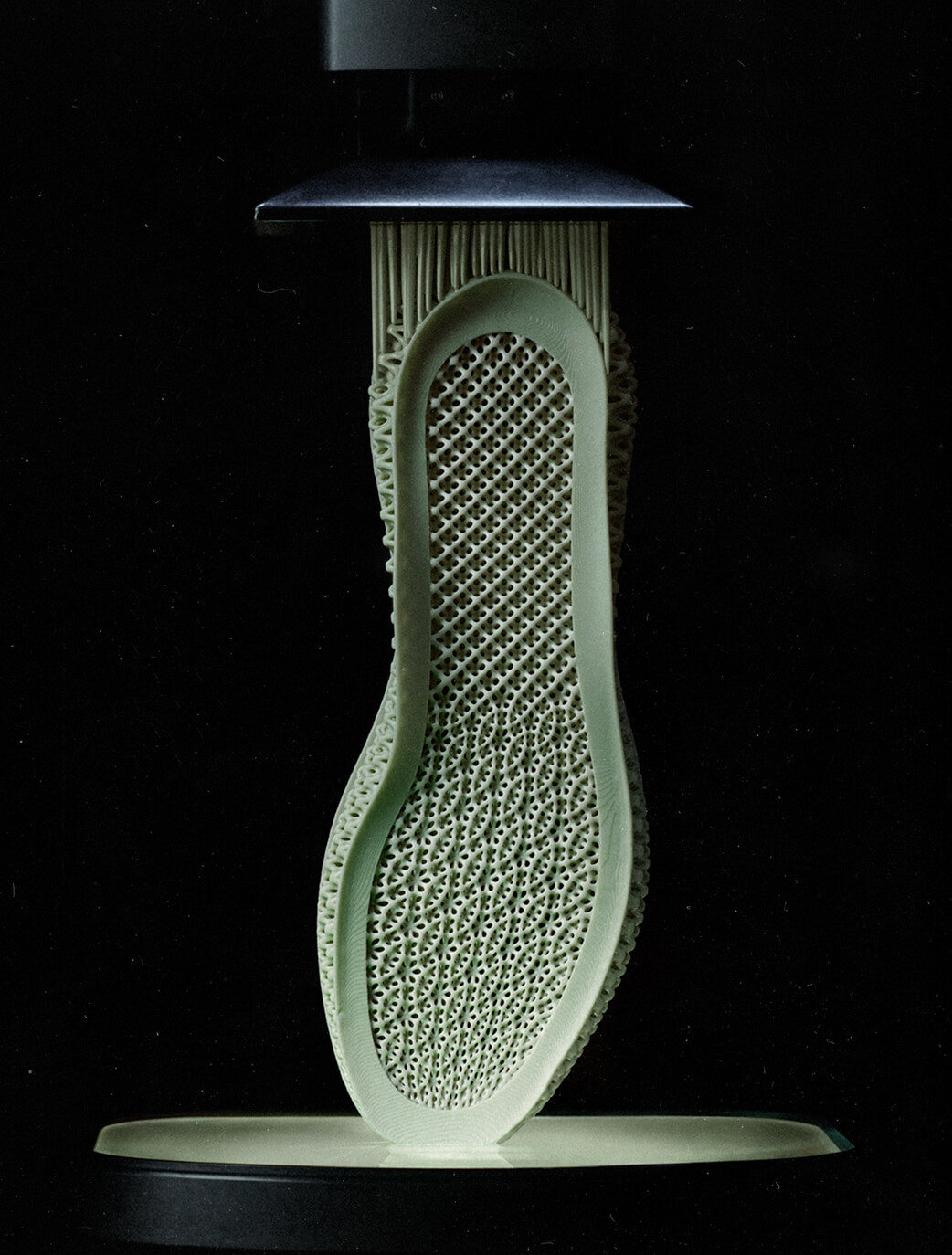

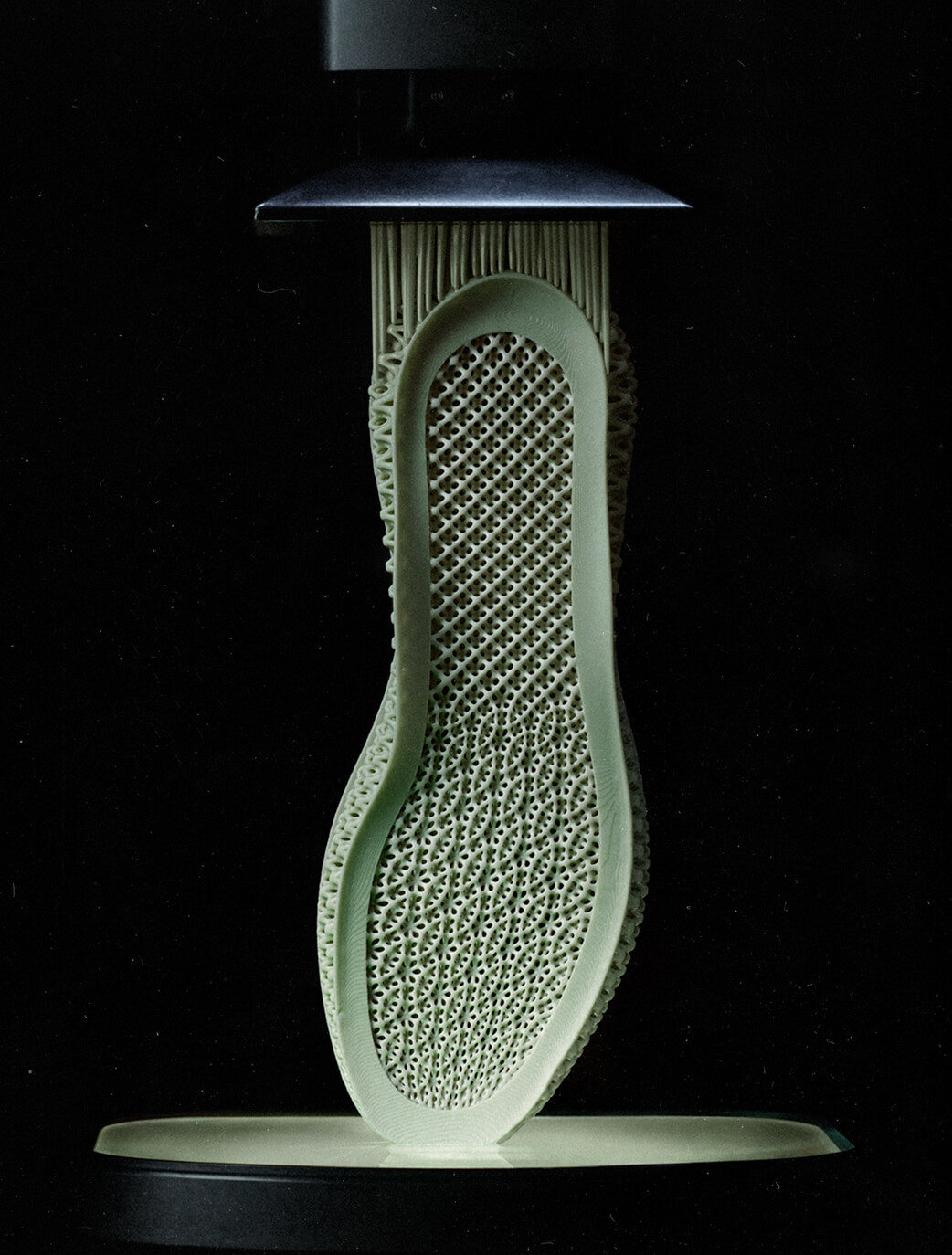

Lightweight Sneakers & Performance Enhancement: 3D printing allows for the creation of complex designs and intricate lattice structures within the midsole. This results in incredibly lightweight sneakers that offer superior cushioning, responsiveness, and support, enhancing athletic performance. The precise control over material placement optimizes performance for specific activities.

-

Manufacturing Efficiency: On-demand production through 3D printing minimizes overstocking and reduces inventory costs. This approach is more agile and responsive to market demand, allowing Adidas to produce shoes only when and where they are needed. This localized production also reduces transportation costs and the associated carbon emissions.

-

Bullet Points Summarizing Advantages:

- Reduced material waste and increased sustainability.

- Highly personalized fits and designs tailored to individual needs.

- Lightweight yet high-performance designs with optimized cushioning and support.

- Efficient on-demand production minimizing waste and inventory.

- Reduced transportation costs and a lower carbon footprint.

The Manufacturing Process of Adidas' 3D-Printed Sneakers

The journey from digital design to finished product is a fascinating blend of technology and precision. Adidas' 3D-printed sneaker manufacturing process involves several key steps:

-

Digital Design and Modeling: The process begins with advanced digital design software, where designers create intricate 3D models of the sneaker, meticulously crafting every detail. This allows for unparalleled creative freedom and the exploration of innovative designs previously impossible with traditional methods.

-

Material Selection: Adidas carefully selects high-performance materials suitable for 3D printing, often incorporating recycled materials to further enhance the sustainability of the process. Thermoplastic polyurethane (TPU) is a common choice due to its flexibility, durability, and printability.

-

3D Printing (Additive Manufacturing): The actual printing involves a layer-by-layer process where the chosen material is precisely deposited according to the digital design. Adidas utilizes advanced additive manufacturing techniques to create complex structures and ensure high precision. This process often takes place in Adidas' Speedfactory, a cutting-edge facility dedicated to automated shoe production.

-

Post-Processing: Once printed, the sneakers undergo post-processing steps, such as cleaning, finishing, and quality control checks to ensure they meet Adidas’ rigorous standards. These final steps refine the product and prepare it for market.

-

Bullet Points Summarizing the Process:

- Advanced digital design and modeling.

- Selection of high-performance and sustainable materials (e.g., TPU, recycled materials).

- Layer-by-layer 3D printing using additive manufacturing technology.

- Post-processing steps including cleaning and quality control.

- Utilization of Adidas’ Speedfactory for automated production.

Examples of Adidas' 3D-Printed Sneaker Models and Their Features

Adidas has already launched several groundbreaking 3D-printed sneaker models, showcasing the potential of this technology.

-

Adidas Futurecraft 4D: This model features a unique 3D-printed midsole with a lattice structure designed for optimal cushioning and energy return. Reviews praise its comfort and responsiveness.

-

Adidas AM4: This line demonstrates the potential for mass customization, allowing consumers to choose specific features and designs to create a truly personalized running shoe.

-

Bullet Points Highlighting Specific Models:

- Adidas Futurecraft 4D: Known for its innovative 3D-printed midsole offering superior cushioning and responsiveness.

- Adidas AM4: A prime example of mass customization, offering personalized features and designs. [Include images/videos of the models here]

Further models and features could be added as new releases occur. This section should remain updated to reflect current offerings.

The Future of Adidas' 3D-Printed Sneaker Technology

The future of Adidas' 3D-printed sneaker technology is bright, brimming with potential for innovation and sustainability.

-

Increased Production and Affordability: Adidas is actively working to scale up production, making 3D-printed sneakers more accessible and affordable to a wider range of consumers.

-

Advanced Materials and Technologies: Expect to see the integration of even more advanced materials and technologies, further enhancing performance, comfort, and sustainability. Biodegradable and completely recycled materials are a key focus for future development.

-

Further Personalization: Beyond size and color, future iterations may offer even more granular customization options, such as personalized arch support or cushioning based on individual foot scans and running styles.

-

Bullet Points on Future Developments:

- Increased production capacity leading to lower prices.

- Integration of innovative, sustainable, and high-performance materials.

- Enhanced personalization options beyond basic size and color choices.

- Potential for personalized comfort features based on individual foot scans and biometrics.

Conclusion

Adidas' 3D-printed sneaker technology represents a significant leap forward in footwear innovation. The advantages are clear: enhanced sustainability, unparalleled customization, and superior performance. By embracing this technology, Adidas is not only revolutionizing its own production but also shaping the future of the entire footwear industry. Discover the future of footwear with Adidas' groundbreaking 3D-printed sneaker technology. Explore the latest models and innovations today! [Link to Adidas website]

Featured Posts

-

Mask Singer 2025 L Autruche Revelee Surprise De Chantal Ladesou Et Deception De Laurent Ruquier

May 12, 2025

Mask Singer 2025 L Autruche Revelee Surprise De Chantal Ladesou Et Deception De Laurent Ruquier

May 12, 2025 -

Ufc 315 Full Main Card Announced Belal Muhammad Vs Jack Della Maddalena Headlines

May 12, 2025

Ufc 315 Full Main Card Announced Belal Muhammad Vs Jack Della Maddalena Headlines

May 12, 2025 -

John Wick 5 Update New Details Revealed Release Date A Mystery

May 12, 2025

John Wick 5 Update New Details Revealed Release Date A Mystery

May 12, 2025 -

Mls Flytt Foer Thomas Mueller Nya Uppgifter Dyker Upp

May 12, 2025

Mls Flytt Foer Thomas Mueller Nya Uppgifter Dyker Upp

May 12, 2025 -

Adam Sandlers Real Life Romance A New Netflix Movie Tradition

May 12, 2025

Adam Sandlers Real Life Romance A New Netflix Movie Tradition

May 12, 2025