F-35 Program's Inventory Problems: A Pentagon Audit Failure

Table of Contents

The Audit's Key Findings: Unreliable Data and Missing Parts

The Pentagon audit exposed deep-seated flaws in the F-35's inventory management, revealing two major issues: inaccurate inventory data and a chronic shortage of critical spare parts. These problems are not isolated incidents but rather symptoms of a larger systemic failure.

Inaccurate Inventory Data

The audit uncovered widespread discrepancies between the Pentagon's reported inventory of F-35 parts and the actual quantities available. This unreliable data significantly hinders maintenance, repair, and overall operational readiness. The lack of accurate data makes effective planning and resource allocation nearly impossible.

- Significant discrepancies were found across multiple F-35 variants (A, B, and C), indicating a widespread problem not limited to a single model.

- Inconsistent data reporting practices across different air bases and maintenance facilities highlight a lack of standardization and integration within the system. Each location seems to operate in a data silo.

- The absence of a centralized, real-time inventory management system prevents a clear, holistic view of available parts. This lack of visibility makes timely decision-making extremely difficult.

- Difficulties in tracking parts throughout the complex supply chain, from manufacturers to depots to individual air bases, contribute to the inaccurate data and delays. Visibility into the entire supply chain is paramount.

Chronic Shortage of Critical Spare Parts

Beyond inaccurate data, the audit revealed a persistent shortage of essential spare parts, leading to extended aircraft downtime and inflated maintenance costs. This shortage directly impacts the F-35's operational capabilities.

- Delays in procurement and delivery of spare parts are frequently reported, leaving aircraft grounded and unable to fulfill their missions.

- Inadequate forecasting of parts demand has resulted in consistent under-stocking of crucial components. Better predictive modeling is desperately needed.

- Supply chain vulnerabilities, such as reliance on single-source suppliers or geopolitical instability, impact the timely acquisition of necessary parts. A more robust and diversified supply chain is a must.

- The increased risk of mission failure due to a lack of readily available parts poses a serious threat to national security and operational effectiveness.

Consequences of Inventory Management Failures

The consequences of these inventory management failures extend beyond simple logistical issues; they have serious implications for the F-35 program's overall effectiveness and cost.

Reduced Operational Readiness

The inventory problems directly translate into a reduced operational readiness for the F-35 fleet. This means fewer aircraft are available for deployment and training.

- Increased aircraft ground time due to the lack of spare parts significantly reduces the number of flying hours.

- Reduced flight hours and training opportunities hinder pilot proficiency and overall mission readiness.

- The impact on mission capabilities and national security is substantial, raising concerns about the F-35's ability to fulfill its intended role.

Escalating Costs

The inefficiencies in inventory management contribute to significantly higher maintenance and repair costs, adding to the already substantial expense of the F-35 program. Poor management equates to wasted taxpayer money.

- Increased costs associated with expedited parts procurement are incurred due to the constant need to quickly obtain missing components.

- Higher labor costs result from prolonged maintenance periods caused by part shortages.

- The potential for obsolescence of parts due to delays further exacerbates the financial burden.

Potential Solutions and Recommendations

Addressing the F-35's inventory problems requires a multi-pronged approach focusing on both technological upgrades and strategic supply chain improvements.

Implementing a Modernized Inventory System

A robust, integrated inventory management system is paramount to improving data accuracy and effectively tracking parts throughout the supply chain.

- Investing in advanced inventory tracking technologies, such as RFID or blockchain, can provide real-time visibility into part locations and status.

- Standardizing data reporting practices across all F-35 maintenance facilities is essential for creating a unified and accurate data picture.

- Implementing real-time inventory visibility across the supply chain allows for proactive identification of potential shortages and timely intervention.

Strengthening Supply Chain Resilience

Measures must be taken to improve the reliability and resilience of the F-35 supply chain, reducing dependency on single sources and mitigating risks.

- Diversifying suppliers and establishing backup sources for critical parts minimizes the impact of disruptions.

- Improving forecasting and demand planning processes through advanced analytics can help to accurately predict part needs.

- Strengthening partnerships with industry partners fosters collaboration and improves communication throughout the supply chain.

Conclusion

The Pentagon audit's findings on the F-35 program's inventory problems reveal significant systemic failures within the program's logistics infrastructure. These issues directly impact operational readiness, escalate costs, and raise serious concerns about the program's long-term viability. Addressing these challenges requires immediate action, including the implementation of a modernized inventory management system and the strengthening of the F-35 supply chain. Failure to effectively manage the F-35's inventory will continue to undermine the program's effectiveness and represent a significant waste of taxpayer dollars. Urgent action is needed to resolve these F-35 inventory problems and ensure the long-term success of this critical defense program. The future of the F-35 depends on a swift and decisive response to these critical F-35 logistical challenges.

Featured Posts

-

Nba Skills Challenge 2025 Players Teams And The Competition Format

Apr 30, 2025

Nba Skills Challenge 2025 Players Teams And The Competition Format

Apr 30, 2025 -

Analyse Du Document Amf Cp 2025 E1021792 De Seb S A 24 Fevrier 2025

Apr 30, 2025

Analyse Du Document Amf Cp 2025 E1021792 De Seb S A 24 Fevrier 2025

Apr 30, 2025 -

Dagskra Yfir Meistaradeildina Og Nba Leiki I Bonusdeildinni

Apr 30, 2025

Dagskra Yfir Meistaradeildina Og Nba Leiki I Bonusdeildinni

Apr 30, 2025 -

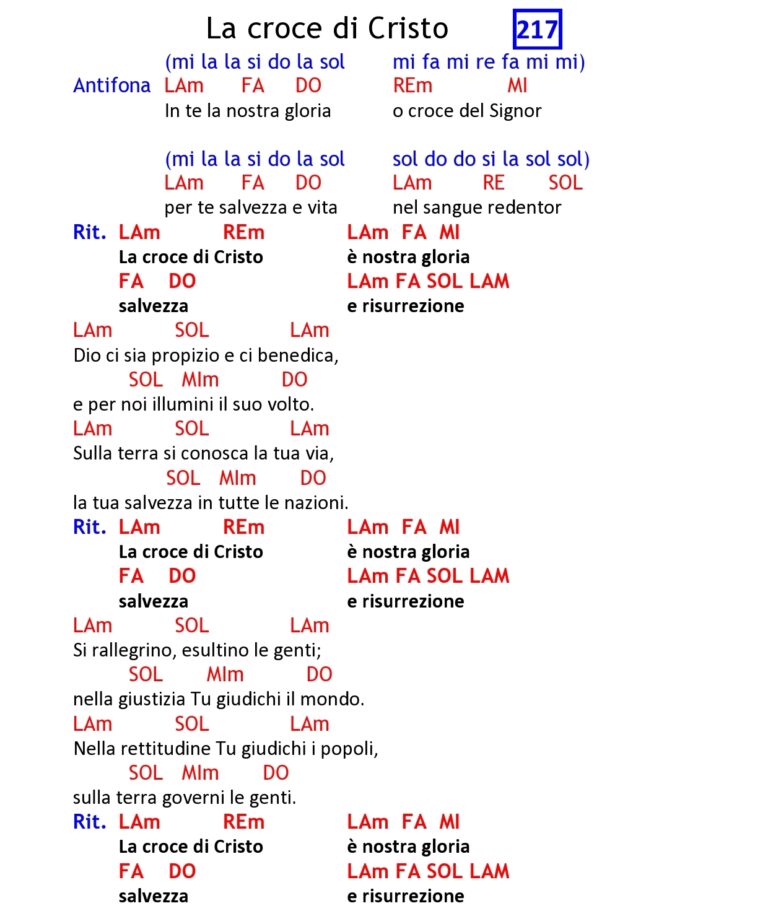

La Croce Di Cristo La Perspectiva Di Feltri Nel Venerdi Santo

Apr 30, 2025

La Croce Di Cristo La Perspectiva Di Feltri Nel Venerdi Santo

Apr 30, 2025 -

Strategy Acquires 6 556 Bitcoin For 555 8 Million Full Details Revealed

Apr 30, 2025

Strategy Acquires 6 556 Bitcoin For 555 8 Million Full Details Revealed

Apr 30, 2025