Honda's EV Production Slowdown: The $15 Billion Ontario Project And Market Factors

Table of Contents

The $15 Billion Ontario Project: A Deep Dive

Honda's commitment to electric vehicles is evident in its substantial investment in a new EV plant in Ontario, Canada. This $15 billion project represents a significant bet on the future of electric mobility and is expected to significantly impact the Canadian automotive landscape. The plant is slated to produce a range of electric vehicles, contributing to Honda's global EV production capacity. The project promises significant job creation and economic benefits for the province.

However, the Ontario EV plant's development hasn't been without its hurdles. Construction and setup have faced unforeseen challenges, resulting in delays to the originally anticipated timeline.

- Timeline of project milestones (anticipated vs. actual): While initial projections targeted a specific production start date, delays have pushed this back, impacting the overall project timeline. Detailed timelines are still emerging as Honda navigates these challenges.

- Key partnerships and collaborations involved: Honda is collaborating with various suppliers and technology partners to ensure a smooth operation of the Ontario plant. These collaborations are crucial for securing the necessary components and expertise for efficient EV production.

- Government incentives and support received: The Ontario government has provided significant incentives and support to attract Honda's investment. This support includes tax breaks, infrastructure development, and workforce training programs.

- Potential risks and uncertainties associated with the project: Despite the significant investment, the project still faces inherent risks, including potential fluctuations in demand for EVs, changes in government policies, and unforeseen supply chain disruptions.

Global Supply Chain Disruptions and their Impact on Honda's EV Production

The global automotive industry, including the EV sector, has been significantly impacted by supply chain disruptions. Honda's EV production has not been immune to these challenges. The shortage of semiconductors, crucial for vehicle electronics, and the instability in the supply of battery materials are major bottlenecks.

Geopolitical instability and trade tensions further complicate the situation, impacting the availability and cost of critical components. These disruptions have directly affected the timeline and budget of the Ontario project, causing delays and increasing production costs.

- Specific examples of component shortages impacting production: The lack of specific microchips and certain battery materials has directly limited Honda's ability to manufacture EVs at the desired rate.

- Strategies Honda is employing to mitigate supply chain risks: Honda is actively working to diversify its supply sources, build stronger relationships with suppliers, and explore alternative sourcing strategies to mitigate the impact of future disruptions.

- The potential long-term consequences of these disruptions on the EV market: These disruptions could lead to higher EV prices, slower market penetration, and increased competition for scarce resources.

Competition in the Electric Vehicle Market: Honda's Position and Challenges

The global EV market is incredibly competitive, with established players and new entrants vying for market share. Companies like Tesla, Volkswagen, and BYD are leading the charge, each with its own distinct strategies and technological advantages.

Honda's current EV offerings, while showing promise, face significant challenges in competing with these established brands. Factors such as pricing, technology, and brand perception play a critical role in consumer choice.

- Key competitors and their market strategies: Tesla's focus on direct-to-consumer sales and cutting-edge technology, Volkswagen's broad portfolio of EVs, and BYD's aggressive expansion in various markets all present significant challenges.

- Analysis of Honda's EV pricing and technology: Honda needs to strategize its pricing and technology offerings to better compete with its rivals, making sure they are competitive in both aspects.

- Consumer demand for Honda's EVs compared to competitors: Consumer surveys and market data indicate Honda needs to enhance its brand presence and consumer appeal in the EV sector.

- Future outlook for Honda's competitiveness in the EV market: Honda’s success hinges on its ability to overcome its current challenges, innovate further, and adapt to the fast-changing dynamics of the EV market.

Battery Technology and its Role in Honda's EV Production Slowdown

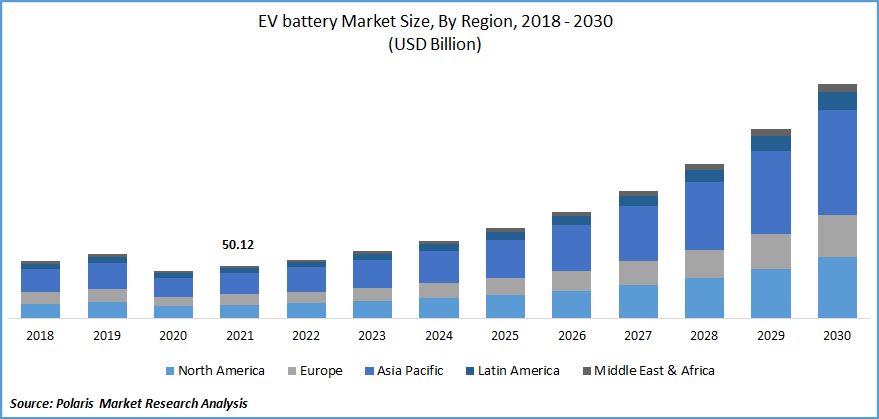

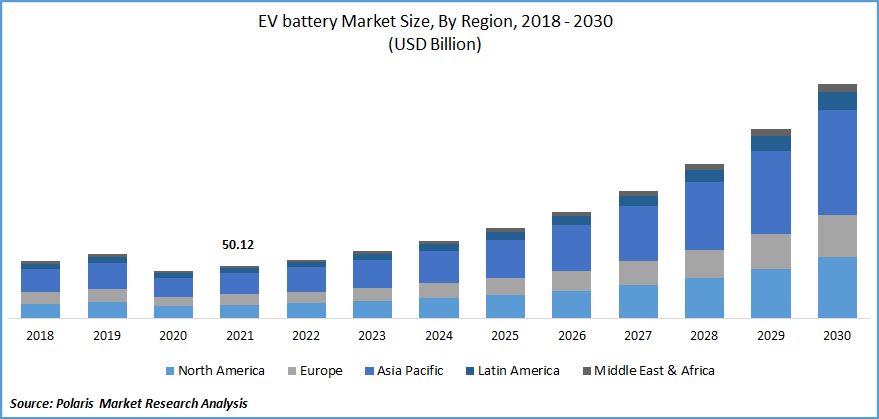

Battery technology is a pivotal factor in EV production, impacting performance, range, and charging times. Challenges in battery production, including sourcing raw materials like lithium and cobalt, and building sufficient manufacturing capacity, are slowing down EV production across the industry, including Honda.

Advancements in battery technology are crucial for increasing EV range, reducing charging times, and improving overall performance. Honda's strategy in this area will play a crucial role in its future competitiveness.

- Different battery chemistries and their advantages/disadvantages: Honda needs to carefully consider various battery technologies and their trade-offs to choose the optimal solution for its vehicles.

- The role of battery range and charging times in consumer choice: Consumers prioritize longer ranges and shorter charging times, making battery technology a critical differentiator.

- Honda's battery technology strategy and partnerships: Honda needs to strengthen its partnerships in the battery technology sector to ensure sufficient supply and technological advantage.

Honda's EV Future: Navigating the Challenges Ahead

In conclusion, Honda's EV production slowdown is a result of a confluence of factors: supply chain disruptions, intense competition in the EV market, and the ongoing evolution of battery technology. The $15 billion Ontario project represents a significant long-term investment in Honda's EV strategy. However, successfully navigating these challenges requires strategic adaptation, robust supply chain management, and a compelling product offering.

While the road ahead presents obstacles, Honda’s commitment to the EV market, coupled with innovative solutions and strategic partnerships, offers a path toward success. Stay informed about developments in Honda's EV production and the evolving electric vehicle market by following future updates on Honda's EV strategy and the progress of the Ontario plant. Keywords: Honda EV news, future of electric vehicles, Honda's EV investment.

Featured Posts

-

The Hemsley Return A Case Study In Boomerang Ceo Effectiveness At United Health

May 15, 2025

The Hemsley Return A Case Study In Boomerang Ceo Effectiveness At United Health

May 15, 2025 -

Maximize Your Mlb Dfs Roi May 8th Sleeper Picks And Hitter To Fade

May 15, 2025

Maximize Your Mlb Dfs Roi May 8th Sleeper Picks And Hitter To Fade

May 15, 2025 -

Proyek Psn Giant Sea Wall Menko Ahy Rapat Jadwal Pembangunan Terbaru

May 15, 2025

Proyek Psn Giant Sea Wall Menko Ahy Rapat Jadwal Pembangunan Terbaru

May 15, 2025 -

Foot Lockers Q4 2024 Earnings Report A Deep Dive Into The Lace Up Plan

May 15, 2025

Foot Lockers Q4 2024 Earnings Report A Deep Dive Into The Lace Up Plan

May 15, 2025 -

Did Elizabeth Warren Successfully Defend Joe Bidens Mental State

May 15, 2025

Did Elizabeth Warren Successfully Defend Joe Bidens Mental State

May 15, 2025