Is Dysprosium The Next Big Bottleneck For Electric Vehicle Production?

Table of Contents

Dysprosium's Crucial Role in Electric Vehicle Motors

Electric vehicle motors rely heavily on powerful neodymium magnets for their efficient operation. These magnets aren't just any magnets; they require specific properties to deliver the torque and speed necessary for optimal EV performance. This is where dysprosium comes in. It's a key component in these neodymium magnets, significantly enhancing their performance characteristics.

Dysprosium-enhanced neodymium magnets boast superior properties compared to alternatives. These superior qualities translate directly into better EV performance and efficiency.

- Increased magnetic strength and durability: Dysprosium contributes to a higher coercivity, meaning the magnets resist demagnetization even under extreme conditions, ensuring consistent motor performance throughout the EV's lifespan.

- Higher operating temperatures: EVs generate significant heat, and dysprosium helps the magnets maintain their strength and performance at high operating temperatures, crucial for consistent motor function.

- Improved efficiency in electric motors: The enhanced magnetic properties lead to reduced energy losses within the motor, improving the overall efficiency of the EV and extending its range. This efficiency boost is crucial for maximizing battery life and minimizing energy consumption.

The Current Supply Chain and Geopolitical Risks

The global supply chain for dysprosium is highly concentrated, raising significant geopolitical concerns. A significant portion of dysprosium mining and processing is dominated by China. This geographic concentration presents several substantial risks:

- China's control over a significant portion of global dysprosium production: This creates a vulnerability for nations heavily reliant on EVs, placing them at the mercy of China's policies and potential export restrictions.

- Risks associated with reliance on a single major supplier: Political instability in China, trade disputes, or even natural disasters could severely disrupt the global supply of dysprosium, causing significant production delays and price spikes.

- Potential for price volatility and supply shortages: The limited supply and concentrated production create a volatile market, prone to price fluctuations and potential shortages that can severely impact EV manufacturers.

Exploring Alternative Materials and Technologies

The inherent risks associated with dysprosium dependence are driving intensive research into alternative materials and technologies. Scientists and engineers are exploring various avenues to reduce or eliminate the need for dysprosium in EV magnets.

- Research into alternative rare-earth elements: Scientists are investigating other rare-earth elements that could partially or completely replace dysprosium in magnet production, though these often come with their own challenges.

- Development of improved magnet designs: Optimizing magnet design can lessen the reliance on dysprosium by improving the overall efficiency of the magnet, reducing the amount of dysprosium needed to achieve the same performance.

- Exploration of non-rare-earth magnet technologies: Research is also focusing on entirely different magnet technologies that do not rely on rare-earth elements, although these often lack the same performance characteristics as neodymium magnets. However, advancements in this area could significantly reduce or eliminate dysprosium dependence in the long term.

The Impact on Electric Vehicle Production and Pricing

The potential scarcity of dysprosium has significant implications for the EV industry and consumers. The consequences extend beyond just the availability of EVs:

- Increased manufacturing costs: Higher dysprosium prices directly translate into increased manufacturing costs for electric vehicles, impacting profitability for manufacturers.

- Potential delays in EV production: Supply chain disruptions could lead to significant delays in EV production, slowing down the transition to electric mobility.

- Impact on EV affordability and accessibility: Increased production costs will likely lead to higher EV prices, potentially hindering consumer adoption and reducing the accessibility of EVs for a larger segment of the population.

Conclusion: Addressing the Dysprosium Bottleneck in Electric Vehicle Production

Dysprosium's critical role in electric vehicle production cannot be overstated. The current reliance on a geographically concentrated supply chain creates significant geopolitical risks and potential for supply disruptions. Price volatility and potential shortages could severely impact EV production volumes, pricing, and ultimately, the widespread adoption of EVs.

To ensure the continued growth of the electric vehicle market and avoid a dysprosium bottleneck, proactive measures are essential. This includes increased investment in research and development of alternative materials and technologies, the diversification of dysprosium supply chains, and the exploration of sustainable mining practices. Addressing the dysprosium challenge is crucial for achieving a truly sustainable and accessible electric vehicle future. We need innovative solutions and collaborative efforts to prevent dysprosium from becoming a major obstacle in the global transition to electric mobility.

Featured Posts

-

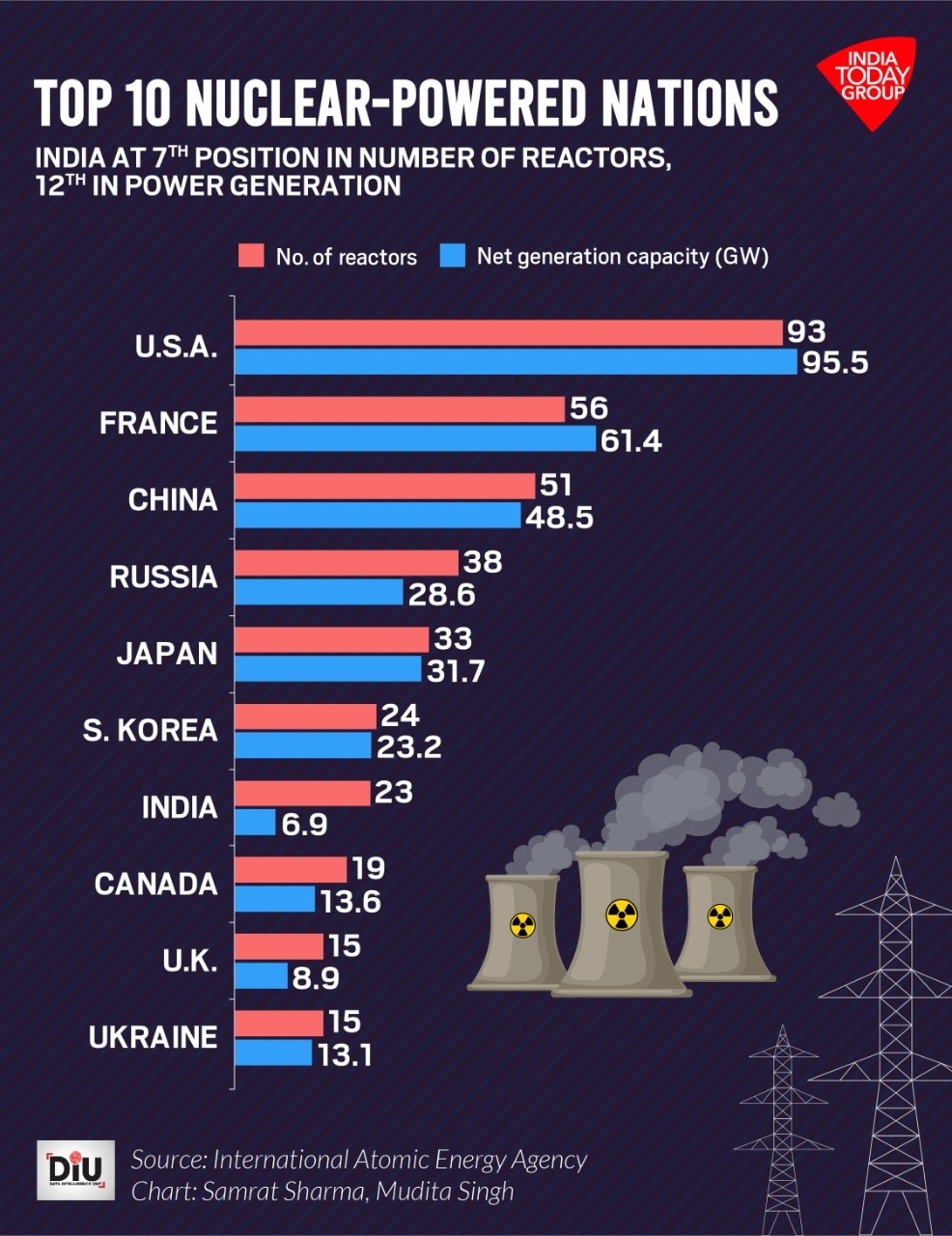

Chinas Nuclear Power Expansion 10 New Reactors Approved

Apr 29, 2025

Chinas Nuclear Power Expansion 10 New Reactors Approved

Apr 29, 2025 -

Access To Birth Control Examining The Impact Of Over The Counter Options Post Roe

Apr 29, 2025

Access To Birth Control Examining The Impact Of Over The Counter Options Post Roe

Apr 29, 2025 -

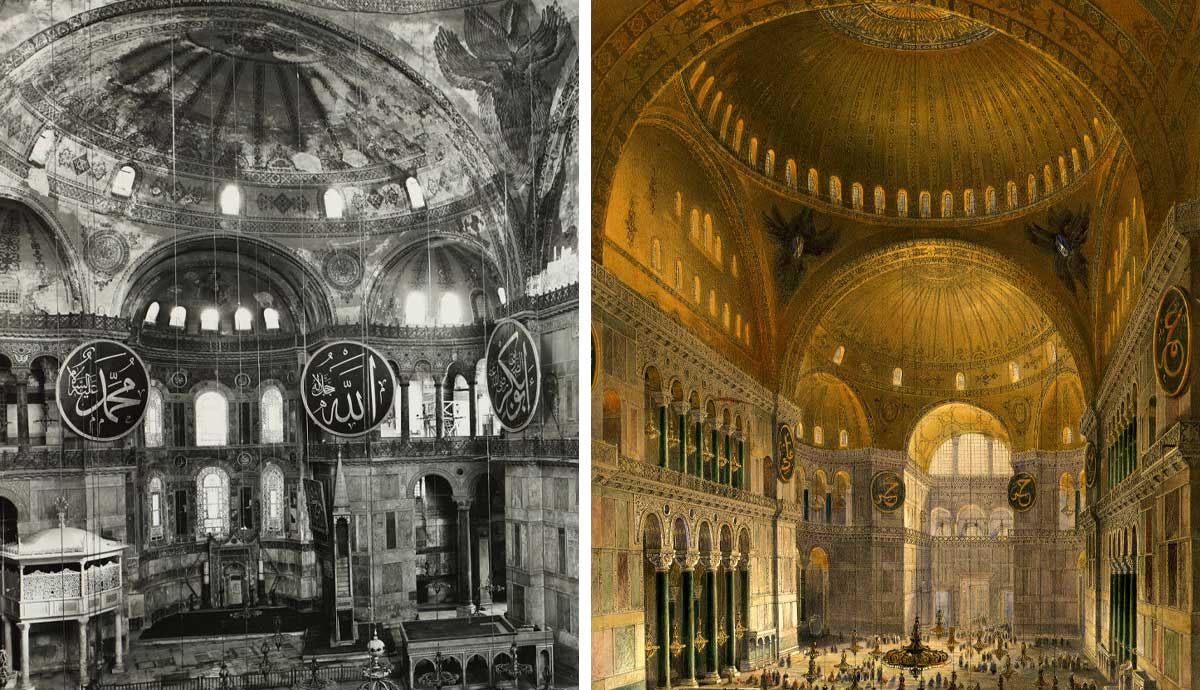

Hagia Sophia A 1600 Year History Of Survival

Apr 29, 2025

Hagia Sophia A 1600 Year History Of Survival

Apr 29, 2025 -

Cocaine Found At White House Secret Service Completes Investigation

Apr 29, 2025

Cocaine Found At White House Secret Service Completes Investigation

Apr 29, 2025 -

Ftc Probes Open Ai Implications For Ai Development And Regulation

Apr 29, 2025

Ftc Probes Open Ai Implications For Ai Development And Regulation

Apr 29, 2025

Latest Posts

-

Finding Nostalgia Older Adults Embrace You Tube For Classic Tv

Apr 29, 2025

Finding Nostalgia Older Adults Embrace You Tube For Classic Tv

Apr 29, 2025 -

You Tube A New Home For Older Viewers Favorite Shows

Apr 29, 2025

You Tube A New Home For Older Viewers Favorite Shows

Apr 29, 2025 -

Finding Comfort And Nostalgia Older Viewers On You Tube

Apr 29, 2025

Finding Comfort And Nostalgia Older Viewers On You Tube

Apr 29, 2025 -

You Tubes Resurgence Why Older Viewers Are Returning

Apr 29, 2025

You Tubes Resurgence Why Older Viewers Are Returning

Apr 29, 2025 -

You Tube A New Platform For Older Viewers Favorite Shows

Apr 29, 2025

You Tube A New Platform For Older Viewers Favorite Shows

Apr 29, 2025