Overcoming Hurdles In Automated Visual Inspection Of Lyophilized Drug Products

Table of Contents

Challenges in Automated Visual Inspection of Lyophilized Products

The inherent fragility and visual variability of lyophilized drug products pose significant difficulties for automated visual inspection systems.

Variations in Lyophilized Cake Appearance

Lyophilization, or freeze-drying, can result in cakes with varying appearances. These variations, while sometimes acceptable, can be difficult to distinguish from actual defects. This inconsistency makes setting consistent acceptance criteria for automated systems a significant hurdle.

- Examples of visual defects: Cracks, fissures, discolorations, incompletely lyophilized areas, particulate matter.

- Impact on drug efficacy and stability: Visual defects can indicate compromised product integrity, potentially affecting efficacy, stability, and shelf life.

- Difficulty in differentiating acceptable variations from defects: Subjective human judgment often plays a significant role in current inspection processes, making automation challenging. The challenge lies in training algorithms to accurately discern acceptable variations from critical defects impacting product quality attributes. This necessitates careful consideration of the lyophilization process parameters and their impact on the final cake appearance.

Dealing with Reflections and Shadows

Reflections from the vial surface and shadows cast by the cake itself can significantly reduce image clarity and hinder accurate defect detection. These artifacts can obscure critical details, leading to false positives or missed defects.

- Types of lighting systems and their impact: Different lighting systems (e.g., coaxial, ring, diffused) have varying impacts on reflection and shadow formation. Coaxial lighting, for instance, is often preferred to minimize reflections, but may not always provide sufficient illumination for detailed defect analysis.

- Advanced image processing techniques for shadow removal and reflection mitigation: Advanced algorithms, including those based on computer vision and image processing, are necessary to remove shadows and correct reflections effectively.

- Material properties influencing light reflection: The vial material (glass, plastic), its surface finish, and the cake's properties influence light reflection. These factors need to be considered when selecting appropriate lighting and imaging parameters.

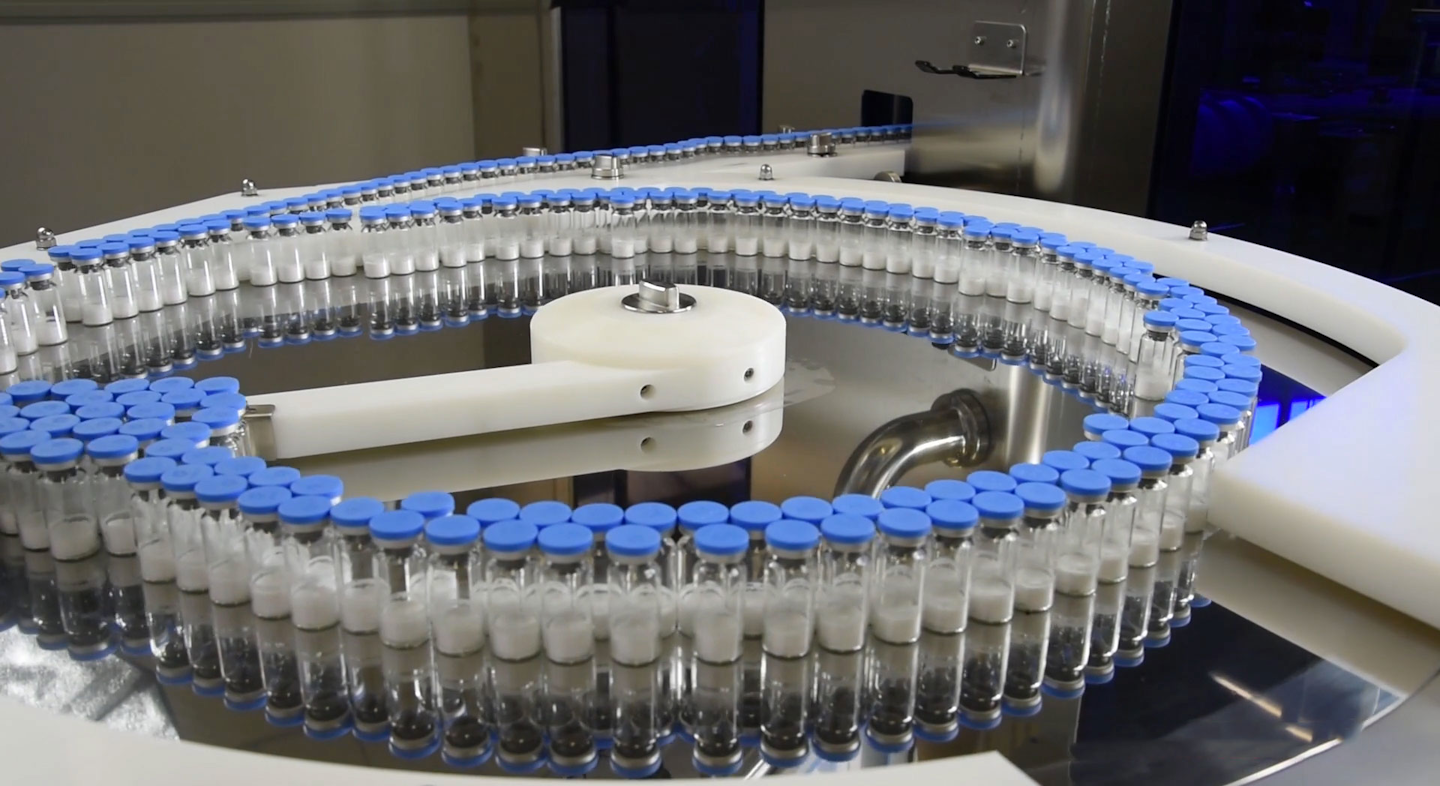

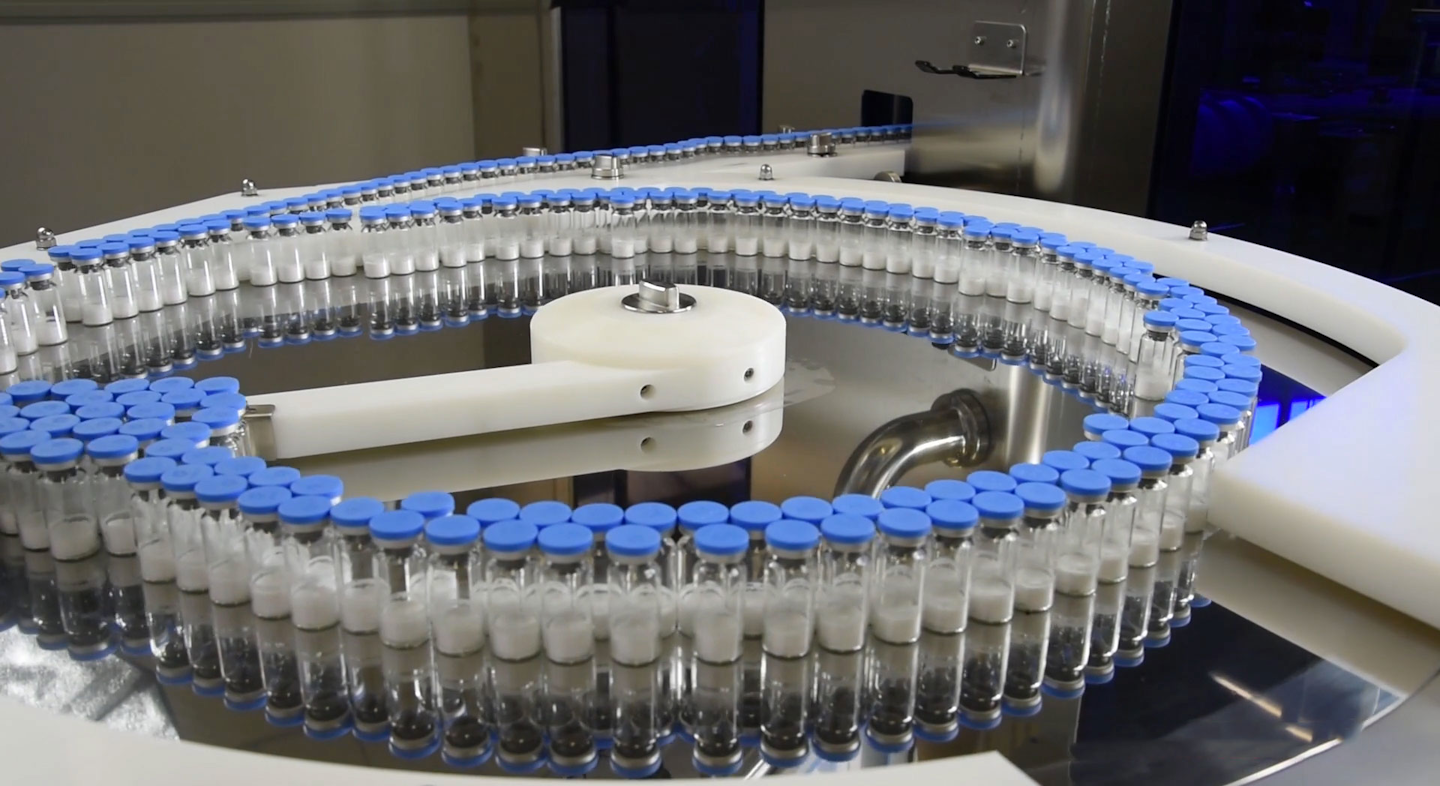

High-Throughput Requirements and Speed

Pharmaceutical production demands high-throughput inspection systems capable of processing numerous vials per minute without compromising accuracy. Current AVI systems often struggle to meet this need.

- Throughput limitations of current AVI systems: Many existing AVI systems struggle to keep up with production demands, leading to bottlenecks and delays.

- The need for faster algorithms and hardware: Faster algorithms and specialized hardware are necessary to improve processing speed without sacrificing accuracy. Real-time inspection is becoming a crucial requirement for efficient high-volume manufacturing.

- Optimization strategies for processing speed without compromising accuracy: Optimizing image acquisition parameters, employing parallel processing techniques, and utilizing efficient data compression methods are vital for achieving the required throughput while maintaining high accuracy in defect detection.

Technological Solutions for Improved Automated Visual Inspection

Significant advancements in image processing, machine learning, and data analytics are providing solutions to address the challenges in AVI of lyophilized drug products.

Advanced Image Processing and Machine Learning Techniques

Advanced algorithms, particularly those based on deep learning and convolutional neural networks (CNNs), are revolutionizing defect detection in AVI. These AI-powered solutions offer improved accuracy and robustness compared to traditional methods.

- Examples of algorithms used for defect detection: CNNs excel at image classification and object detection, making them highly suitable for identifying defects in lyophilized cakes. Other algorithms, such as those based on image segmentation and feature extraction, can complement CNNs for enhanced performance.

- Training datasets for machine learning models: Large, well-annotated datasets are crucial for training effective machine learning models. These datasets must include images representing a wide range of acceptable variations and various types of defects.

- Benefits of AI-powered inspection over traditional methods: AI-powered inspection systems offer improved accuracy, consistency, and objectivity compared to human inspection, leading to reduced human error and improved product quality.

Optimized Lighting and Imaging Systems

Careful selection of lighting conditions and camera systems is paramount for achieving optimal image quality. This involves considering factors such as light source type, intensity, and angle, as well as camera sensor technology and resolution.

- Different lighting techniques (e.g., coaxial, diffused): The choice of lighting technique depends on the specific challenges presented by the product and vial. A combination of techniques may be necessary for optimal illumination.

- Camera sensor technology: High-resolution cameras with appropriate sensitivity are essential for capturing fine details and subtle variations in the lyophilized cake appearance.

- Selection criteria for optimal image acquisition: Factors to consider include camera resolution, field of view, depth of field, and sensor type (e.g., CMOS, CCD).

Data Analytics and Quality Control Integration

Integrating data analytics into AVI systems enables continuous improvement and better quality control. Analyzing inspection data can reveal trends in defect occurrences, allowing for proactive process optimization.

- Using data to identify trends in defect occurrences: Analyzing data on defect types, locations, and frequencies can help identify root causes of defects and guide corrective actions.

- Process optimization based on data insights: Data-driven insights can inform adjustments to the lyophilization process, improving cake quality and reducing defect rates.

- Integrating AVI data with overall quality control systems: Seamless integration of AVI data with other quality control systems allows for a comprehensive view of product quality and facilitates informed decision-making.

Conclusion: Achieving Reliable Automated Visual Inspection of Lyophilized Drug Products

Overcoming the hurdles in automated visual inspection of lyophilized drug products requires a multi-faceted approach. Addressing challenges related to cake appearance variability, reflections, shadows, and throughput demands necessitates the implementation of advanced image processing techniques, machine learning algorithms, and optimized lighting and imaging systems. By leveraging these technologies and integrating data analytics into quality control workflows, pharmaceutical manufacturers can achieve reliable and efficient automated visual inspection, ensuring high-quality lyophilized drug products. Implementing advanced automated visual inspection techniques is crucial for maintaining high standards in the production of lyophilized drug products. Learn more about the latest technologies and solutions to optimize your automated visual inspection processes.

Featured Posts

-

Exploring Montego Bay A Comprehensive Guide

May 11, 2025

Exploring Montego Bay A Comprehensive Guide

May 11, 2025 -

Kim Kardashi An Vo Obleka Ko A Gi Potentsira Ne Zinite Krivini

May 11, 2025

Kim Kardashi An Vo Obleka Ko A Gi Potentsira Ne Zinite Krivini

May 11, 2025 -

Jessica Simpson Back On Stage A 15 Year Hiatus Ends With A Triumphant Performance

May 11, 2025

Jessica Simpson Back On Stage A 15 Year Hiatus Ends With A Triumphant Performance

May 11, 2025 -

Analysis Of Decreasing Earthquake Activity In Santorini

May 11, 2025

Analysis Of Decreasing Earthquake Activity In Santorini

May 11, 2025 -

Can Uruguay Strike Black Gold Offshore Oil Explorations Potential

May 11, 2025

Can Uruguay Strike Black Gold Offshore Oil Explorations Potential

May 11, 2025