Patent Application: AI-Based System For Improved Process Safety

Table of Contents

The Core Technology: AI-Driven Predictive Maintenance

This AI-based system utilizes sophisticated machine learning algorithms to analyze real-time data streamed from a multitude of sensors and control systems within industrial environments. This continuous monitoring allows for proactive identification of potential problems before they escalate into major incidents. The system's core functionality revolves around:

- Predictive analytics for equipment failure: By analyzing historical data and current sensor readings, the system can predict potential equipment failures, allowing for scheduled maintenance to prevent unexpected downtime and costly repairs. This reduces the risk of failures causing safety hazards.

- Early detection of anomalies indicating potential safety hazards: The AI system constantly monitors operational parameters, flagging any deviations from established norms. This early anomaly detection is crucial for preventing accidents.

- AI-powered anomaly detection algorithms for rapid response: Advanced machine learning algorithms sift through vast amounts of data, identifying subtle patterns indicative of potential safety issues that might be missed by human operators. This allows for swift intervention.

- Integration with existing SCADA systems for seamless data flow: The system seamlessly integrates with existing Supervisory Control and Data Acquisition (SCADA) systems, ensuring a smooth data flow without requiring extensive system overhauls. This simplifies implementation and reduces disruption.

This AI-driven predictive maintenance drastically reduces downtime and prevents catastrophic failures. Imagine a chemical plant avoiding a potentially explosive situation by predicting a critical pump failure days in advance, or an oil refinery preventing a spill by detecting a subtle leak before it becomes a major environmental hazard. This proactive approach, enabled by machine learning and SCADA integration, is transformative for process safety.

Enhanced Risk Assessment and Mitigation

Beyond predictive maintenance, the AI system performs a continuous risk assessment, analyzing historical data to identify high-risk scenarios and potential vulnerabilities. This proactive risk mitigation is a key differentiator:

- Real-time risk scoring system based on various parameters (temperature, pressure, flow rates, etc.): The system continuously monitors critical parameters, assigning a real-time risk score based on their combined influence. This provides a clear and immediate understanding of the current safety status.

- Automated alerts and notifications to relevant personnel: When risk scores exceed predefined thresholds, the system automatically generates alerts and notifications, ensuring timely intervention by the appropriate personnel. This rapid response capability is crucial in emergency situations.

- Integration with emergency response systems for faster reaction times: The system seamlessly integrates with existing emergency response systems, streamlining communication and facilitating a more coordinated and effective response to critical incidents. This ensures a faster response time during emergencies.

- Scenario-based simulations to test response protocols: The system can simulate various scenarios to test the effectiveness of existing emergency response protocols, identifying weaknesses and informing improvements to safety procedures. This proactive approach strengthens overall emergency preparedness.

The system's proactive nature prevents accidents before they happen, rather than simply reacting to them after the fact. This represents a paradigm shift in process safety management.

Data Security and Compliance

Data security is paramount. The AI-based system incorporates robust measures to protect sensitive data and ensure compliance with stringent industry regulations, such as IEC 62443:

- Robust cybersecurity measures to protect sensitive data: Multiple layers of security are implemented, including firewalls, intrusion detection systems, and encryption protocols to safeguard sensitive operational data. This safeguards valuable operational and safety data.

- Compliance with relevant safety standards and regulations: The system is designed to meet or exceed all relevant safety standards and regulations, ensuring compliance and minimizing legal risks. Adherence to industry best practices is central to the system’s design.

- Data encryption and access control mechanisms: Data encryption and granular access control mechanisms are implemented to ensure data confidentiality and integrity. Access is restricted based on the principle of least privilege.

- Auditable logging and tracking of system activities: Comprehensive audit trails track all system activities, providing transparency and facilitating investigations in case of incidents. This contributes to accountability and robust security auditing.

The system prioritizes data integrity and confidentiality, ensuring compliance with industry regulations and protecting sensitive information. This is critical for building trust and ensuring long-term usability.

Patent Application Details and Future Outlook

The patent application for this AI-based system for improved process safety is currently pending. Our intellectual property protection strategy focuses on securing broad patent coverage to protect this innovative technology. We are actively exploring technology licensing opportunities and seeking collaborations with leading industrial companies.

- Intellectual property protection strategy: A comprehensive strategy ensures robust protection of our intellectual property rights.

- Licensing opportunities and potential collaborations: We are open to licensing agreements and collaborative partnerships to accelerate the deployment of this life-saving technology.

- Future development and improvements to the system: Ongoing development will focus on enhancing the system's capabilities, incorporating advanced machine learning techniques and expanding its functionalities.

- Expansion into new industrial sectors: The system's adaptability allows for its application across a wide range of industries beyond those initially targeted.

Future improvements include integrating augmented reality for improved visualization of risk assessments and predictive maintenance insights, enhancing the user experience and decision-making capabilities.

Conclusion

This patent application for an AI-based system represents a significant advancement in process safety. By leveraging the power of artificial intelligence, this innovative system offers a proactive and efficient approach to risk management, leading to safer workplaces and reduced operational costs. The system's predictive maintenance capabilities, enhanced risk assessment features, and robust security measures address critical needs in various industries. If you're interested in learning more about this revolutionary technology and potentially licensing our AI-based system for improved process safety, please contact us today. We are actively seeking collaborations to bring this life-saving technology to market and improve industrial process safety worldwide.

Featured Posts

-

Channing Tatum And Inka Williams Couples Trip To Melbourne For The F1 Grand Prix

Apr 30, 2025

Channing Tatum And Inka Williams Couples Trip To Melbourne For The F1 Grand Prix

Apr 30, 2025 -

Revised Yate Train Services Journey Times To Bristol And Gloucester

Apr 30, 2025

Revised Yate Train Services Journey Times To Bristol And Gloucester

Apr 30, 2025 -

Aktualno Prof Khristova Za Situatsiyata S Gripa

Apr 30, 2025

Aktualno Prof Khristova Za Situatsiyata S Gripa

Apr 30, 2025 -

Cleveland Cavaliers Defeat Portland Trail Blazers De Andre Hunters Stellar Game Secures 10th Consecutive Victory

Apr 30, 2025

Cleveland Cavaliers Defeat Portland Trail Blazers De Andre Hunters Stellar Game Secures 10th Consecutive Victory

Apr 30, 2025 -

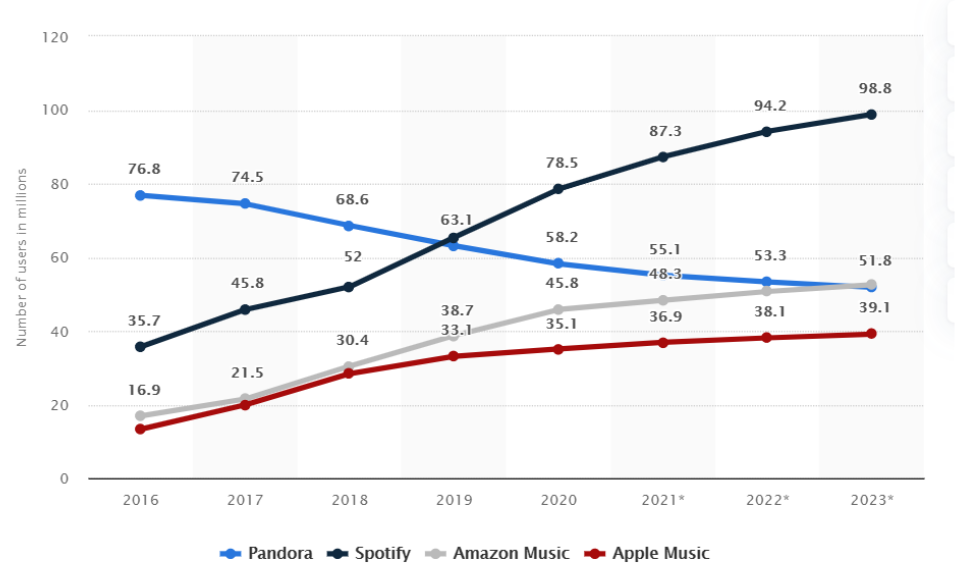

Spotify Subscriber Count 12 Growth Fuels Positive Earnings Report Spot

Apr 30, 2025

Spotify Subscriber Count 12 Growth Fuels Positive Earnings Report Spot

Apr 30, 2025