Reducing Steel's Carbon Footprint: The Role Of Eramet's EraLow

Table of Contents

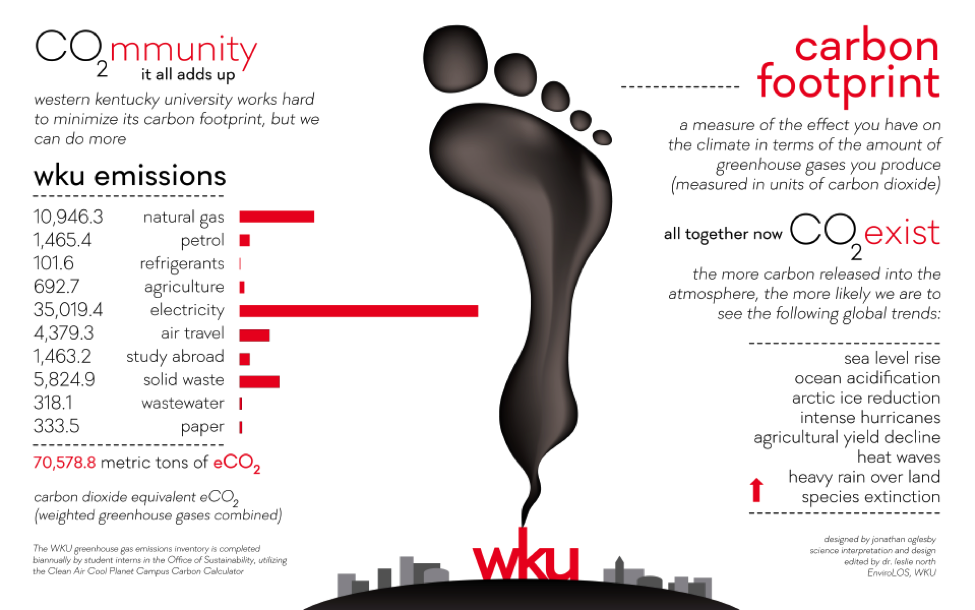

Understanding the Carbon Footprint of Steel Production

The Steelmaking Process and its Emissions

The steelmaking process is inherently energy-intensive and generates substantial greenhouse gas emissions. From iron ore extraction to the blast furnace and basic oxygen furnace stages, significant amounts of CO2, methane, and other gases are released. For instance, the blast furnace process alone contributes a significant percentage (estimates vary depending on the specific processes used) of the overall CO2 footprint. These emissions are largely a result of the energy consumption needed to reach the high temperatures required for steel production and the chemical reactions involved.

The Role of Ferroalloys

Ferroalloys, such as ferrochrome, are crucial components in steelmaking, influencing the final steel's properties and quality. Traditional ferrochrome production methods rely heavily on energy-intensive processes that significantly contribute to greenhouse gas emissions. These processes often involve the use of fossil fuels, leading to substantial CO2 emissions and air pollution.

- Primary greenhouse gases emitted during traditional ferroalloy production: CO2, Methane (CH4), Carbon Monoxide (CO), and Nitrogen Oxides (NOx).

- Percentage contribution of ferroalloy emissions to the total steel production footprint: Estimates range from 5-10%, depending on the alloy and production methods, highlighting the significant impact of this aspect of the steelmaking process.

- Environmental consequences of these emissions: Global warming, air pollution (respiratory problems), and acid rain.

Eramet's eraLow: A Sustainable Solution

The eraLow Production Process

Eramet's eraLow distinguishes itself through its commitment to significantly reducing the carbon footprint of ferrochrome production. This is achieved through a combination of innovative technologies and sustainable practices. The eraLow production process utilizes renewable energy sources, such as hydropower, to reduce reliance on fossil fuels. Furthermore, advancements in energy efficiency throughout the entire process contribute to lower overall emissions. This focus on renewable energy and improved efficiency is central to Eramet’s commitment to producing sustainable steel, resulting in a significantly smaller environmental impact compared to traditional methods. Eramet’s eraLow is a key component in the production of low-carbon steel and green steel, offering a crucial step forward for the industry.

Quantifiable Reductions in Emissions

Using eraLow results in substantial reductions in CO2 emissions. Compared to traditional ferrochrome production methods, Eramet's eraLow boasts a significantly lower carbon footprint. [Insert chart or graph here showing the percentage reduction in CO2 emissions – e.g., "Eramet’s eraLow reduces CO2 emissions by X% compared to traditional methods"]. This translates to a considerable reduction in greenhouse gas emissions per ton of steel produced.

- CO2 emissions comparison: Eramet's eraLow reduces CO2 emissions by [insert percentage or tons of CO2 saved per ton of steel] compared to traditional ferrochrome.

- Renewable energy usage: Eramet leverages [specify type and percentage] of renewable energy in the eraLow production process.

- Certifications and recognitions: [Mention any relevant certifications, like ISO 14001, or sustainability awards received by eraLow].

Benefits Beyond Reduced Emissions

Economic Advantages

Adopting eraLow offers significant economic benefits. Steel producers can leverage the reduced carbon footprint to meet increasingly stringent environmental regulations and potentially avoid or reduce carbon taxes. Furthermore, using eraLow can enhance a company's brand image, attracting environmentally conscious customers and investors. The resulting improved market position and access to environmentally friendly markets provides a strong economic advantage in a sector becoming increasingly focused on sustainability.

Enhanced Steel Quality

While the primary focus is on reducing the environmental impact, using eraLow may also offer improvements in steel quality. [Insert details on any improvements if applicable, e.g., improved consistency, enhanced properties].

- Potential economic benefits for steel producers: Reduced carbon taxes, improved brand reputation, access to new markets.

- Contribution to corporate sustainability goals: Facilitates meeting ESG (Environmental, Social, and Governance) targets and strengthens sustainability reports.

- Advantages for steel consumers: Access to sustainably produced steel, contributing to their own sustainability goals.

Conclusion

Eramet's eraLow offers a compelling solution for reducing the carbon footprint of steel production. By employing renewable energy sources and enhancing energy efficiency, Eramet’s eraLow significantly reduces CO2 emissions compared to traditional methods. This contributes not only to environmental sustainability but also provides economic advantages and enhances the overall quality of the steel produced. Reduce your steel's carbon footprint with eraLow. Discover sustainable steel solutions with Eramet and explore the future of low-carbon steel production with eraLow. Learn more at [link to Eramet's website].

Featured Posts

-

Cocaine Et Violence En Haiti Les Declarations Du President Petro

May 14, 2025

Cocaine Et Violence En Haiti Les Declarations Du President Petro

May 14, 2025 -

Captain America Brave New World Pvod Streaming Options

May 14, 2025

Captain America Brave New World Pvod Streaming Options

May 14, 2025 -

Pokemon Tcg Pocket Building A Winning Charizard Ex A2b 010 Deck And Countering Opponents

May 14, 2025

Pokemon Tcg Pocket Building A Winning Charizard Ex A2b 010 Deck And Countering Opponents

May 14, 2025 -

Every Generations Best Starter Pokemon Expert Analysis And Picks

May 14, 2025

Every Generations Best Starter Pokemon Expert Analysis And Picks

May 14, 2025 -

Fraude Sncf Oqtf Et Exhibition Le Recit De L Incident Impliquant Un Ressortissant Ivoirien Dans Le Nord

May 14, 2025

Fraude Sncf Oqtf Et Exhibition Le Recit De L Incident Impliquant Un Ressortissant Ivoirien Dans Le Nord

May 14, 2025