Review: Adidas' 3D-Printed Footwear - Innovation And Comfort

Table of Contents

Manufacturing Process and Technology of Adidas 3D-Printed Shoes

Additive Manufacturing Explained

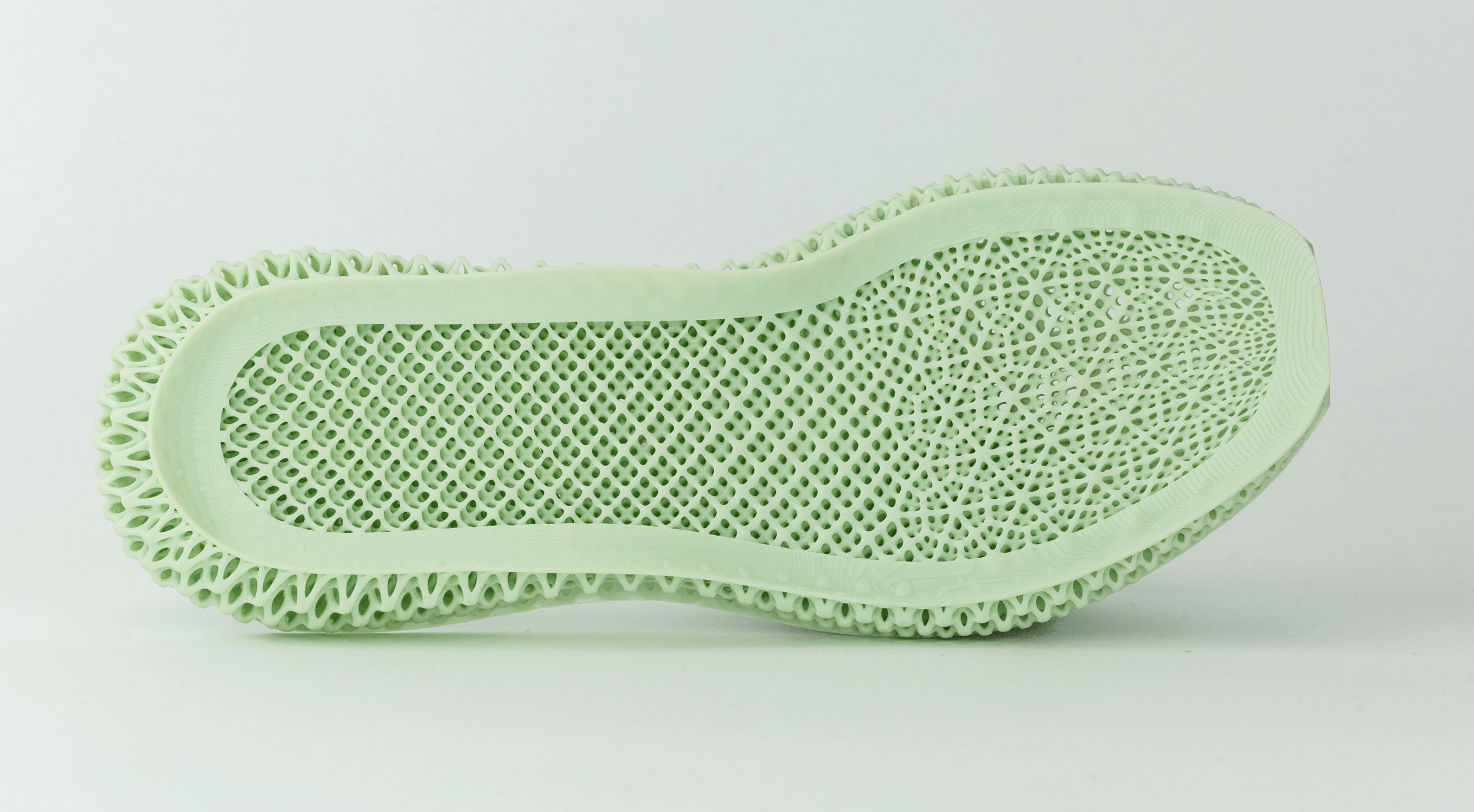

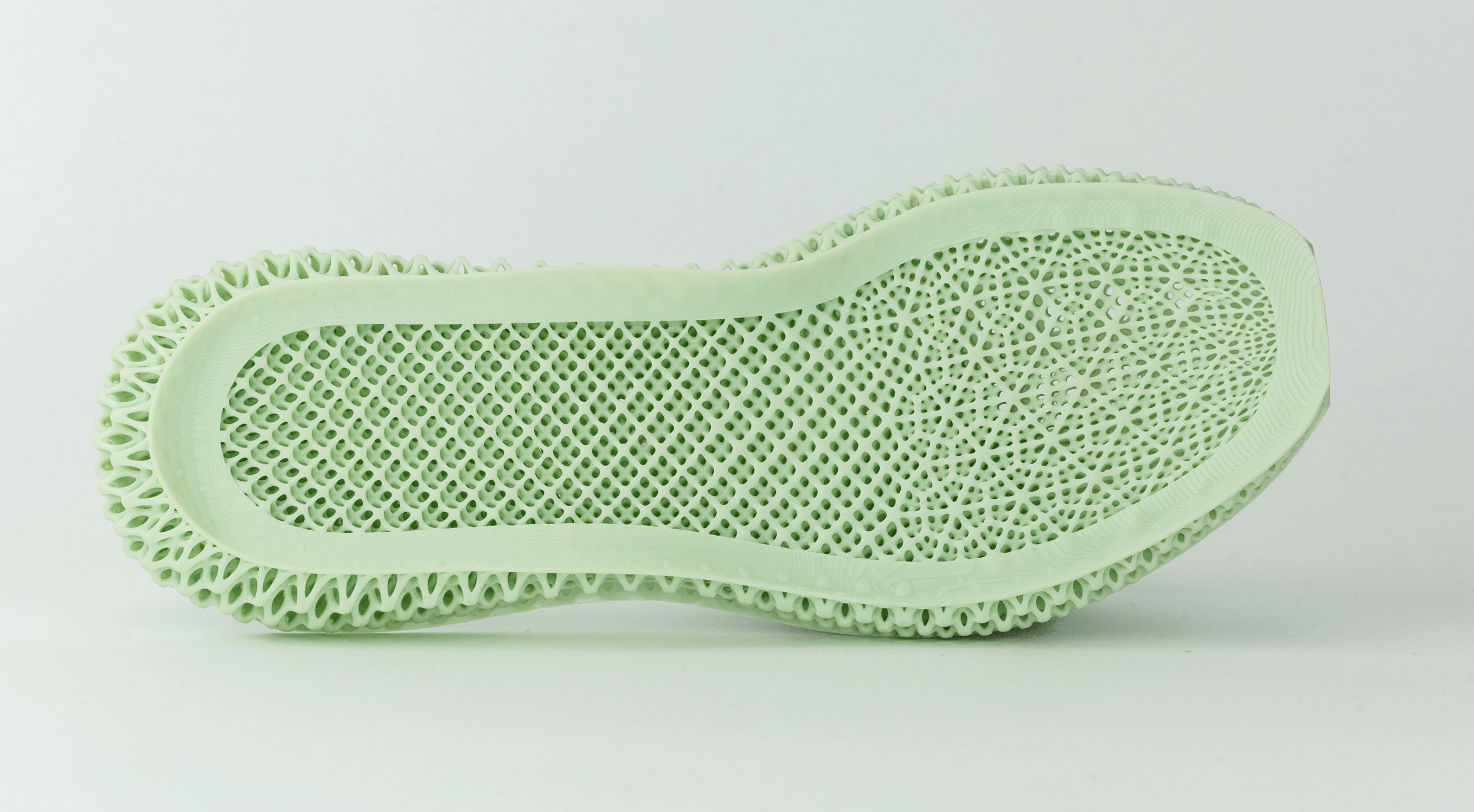

Adidas utilizes advanced additive manufacturing techniques, specifically focusing on selective laser sintering (SLS) for many of its 3D-printed shoes. This process involves using a high-powered laser to fuse layers of thermoplastic polyurethane (TPU) powder, creating a complex three-dimensional structure. The precision of SLS allows for intricate designs and highly customized fits, impossible with traditional manufacturing methods. Furthermore, Adidas increasingly incorporates recycled materials into the TPU blends, demonstrating a commitment to sustainability.

-

Advantages of 3D Printing for Shoe Production:

- Customization: 3D printing allows for highly personalized shoe designs tailored to individual foot shapes and sizes. This results in superior comfort and fit.

- Reduced Waste: Additive manufacturing minimizes material waste compared to traditional subtractive methods. Only the necessary material is used, reducing environmental impact.

- Faster Prototyping: 3D printing enables rapid prototyping, allowing designers to quickly iterate and refine designs before mass production.

- Complex Designs: The technology enables the creation of complex geometric designs that would be impossible or prohibitively expensive to produce using traditional methods.

-

Specific Adidas Technologies: Adidas integrates proprietary algorithms and design software into its 3D printing process to optimize for comfort, performance, and sustainability.

-

Comparison to Traditional Manufacturing: 3D printing offers significantly greater design freedom and customization options compared to traditional shoe manufacturing, which relies on molds and assembly lines. While initial investment costs for 3D printing might be higher, the long-term efficiency gains and reduced waste offer considerable advantages.

Comfort and Fit of Adidas 3D-Printed Footwear

Analyzing the Design Features

The comfort of Adidas 3D-printed footwear stems from its unique design features. The seamless construction, achieved through the 3D printing process, eliminates pressure points and friction commonly found in traditionally manufactured shoes. The ergonomic design closely conforms to the shape of the foot, providing a customized fit that enhances support and stability. Furthermore, many models incorporate breathable materials to keep feet cool and dry.

-

User Experiences and Reviews: Early reviews of Adidas 3D-printed shoes highlight the exceptional comfort and customized fit. Users often praise the lightweight feel and the absence of discomfort during extended wear. (Sources would be cited here if available)

-

Weight and Flexibility: These shoes are typically lightweight and flexible, contributing significantly to overall comfort and ease of movement.

-

Support Features: The design often includes integrated arch support and strategically placed cushioning to provide optimal stability and comfort.

-

Comfort Technologies: Adidas often employs proprietary comfort technologies within its 3D-printed designs, such as specialized cushioning materials and breathable mesh inserts.

Materials and Sustainability in Adidas 3D-Printed Shoes

Eco-Friendly Materials and Production

Adidas is committed to sustainable manufacturing practices. Many of its 3D-printed shoes utilize recycled materials, such as recycled TPU and other sustainable polymers, reducing reliance on virgin resources.

-

Specific Materials and Environmental Impact: The specific materials used vary by model, but Adidas openly communicates its commitment to reducing the environmental impact of its products through material selection and manufacturing processes.

-

Adidas' Sustainability Commitment: Adidas actively researches and develops sustainable materials and manufacturing processes to lessen its environmental footprint.

-

Comparison to Traditional Manufacturing: 3D-printed shoes generally have a lower environmental impact than traditionally manufactured shoes due to reduced material waste and the potential for using recycled materials.

Style and Design of Adidas 3D-Printed Footwear

Aesthetic Appeal and Available Models

Adidas 3D-printed footwear showcases a blend of futuristic aesthetics and athletic functionality. The designs often feature unique geometric patterns and color combinations, creating a visually striking and modern look. The range of available models caters to diverse tastes and preferences.

-

(Images and descriptions of various models would be included here). Examples might include specific model names and highlight their unique design features.

-

Collaborations and Limited Editions: Adidas often collaborates with designers and artists to create limited-edition 3D-printed shoes, enhancing their desirability and collectibility.

-

Overall Aesthetic: The aesthetic is generally considered modern, innovative, and stylish, blending seamlessly with both athletic and casual wear.

Price and Availability of Adidas 3D-Printed Footwear

Cost-Effectiveness and Accessibility

The pricing of Adidas 3D-printed shoes is generally higher than traditionally manufactured shoes, reflecting the advanced technology and customization involved. However, the superior comfort, durability, and sustainability often justify the price for many consumers.

-

Price Range: The price range can vary depending on the model and design features.

-

Where to Purchase: These shoes are available for purchase through Adidas' online store, select Adidas retail locations, and various authorized online retailers.

-

Accessibility and Availability: While accessibility is increasing, the availability of specific models and sizes can be limited at times due to the advanced manufacturing process and high demand.

Conclusion: Final Thoughts on Adidas 3D-Printed Footwear

This review demonstrates that Adidas 3D-printed footwear represents a significant advancement in the footwear industry. The combination of innovative manufacturing processes, exceptional comfort features, a focus on sustainability, and striking designs makes these shoes a compelling option for discerning consumers. While the higher price point might be a barrier for some, the superior comfort, fit, and long-term value often make the investment worthwhile. Ultimately, Adidas' foray into 3D-printed footwear showcases the future of comfortable and sustainable shoe design.

Experience the future of footwear with Adidas' 3D-printed innovation! Explore the comfort and style of Adidas' 3D-printed shoes today! Find your perfect fit with Adidas' revolutionary 3D-printed technology!

Featured Posts

-

Bet365 Bonus Code Nypbet Expert Picks And Odds For Knicks Vs Pistons Series

May 12, 2025

Bet365 Bonus Code Nypbet Expert Picks And Odds For Knicks Vs Pistons Series

May 12, 2025 -

Benny Blanco And Selena Gomez Addressing The Recent Cheating Allegations

May 12, 2025

Benny Blanco And Selena Gomez Addressing The Recent Cheating Allegations

May 12, 2025 -

Naemt Na Antoan Baroan V Ludogorets E Fakt

May 12, 2025

Naemt Na Antoan Baroan V Ludogorets E Fakt

May 12, 2025 -

Thomas Mueller Och Mls Vad Haender Egentligen

May 12, 2025

Thomas Mueller Och Mls Vad Haender Egentligen

May 12, 2025 -

Town Womens Gwalia Match Ipswich Aim For Top Spot

May 12, 2025

Town Womens Gwalia Match Ipswich Aim For Top Spot

May 12, 2025