Right-to-Repair: The US Army's Shift Towards Independent Device Maintenance

Table of Contents

The Rising Costs of Military Equipment Repair and Maintenance

Relying solely on original equipment manufacturers (OEMs) for military maintenance costs a king's ransom. The current system often involves exorbitant fees, lengthy turnaround times, and significant logistical hurdles. This translates to prolonged equipment downtime, hindering operational readiness and impacting mission success. The reliance on external contractors for specialized military repair contributes significantly to these escalating costs.

- Increased reliance on external contractors: Outsourcing repair work to external contractors often leads to inflated pricing and a lack of control over repair timelines.

- High labor costs for specialized technicians: The highly specialized nature of military equipment necessitates technicians with extensive training, driving up labor costs.

- Proprietary parts and limited availability: OEMs often control the supply of parts, creating bottlenecks and potentially inflating prices. This lack of part availability significantly impacts the speed of army equipment repair.

- Logistical challenges in transporting equipment for repair: The size and weight of military equipment can make transportation costly and time-consuming, adding to the overall repair expense.

These factors contribute to a significant drain on defense spending, making the search for more efficient and cost-effective solutions crucial for military logistics and the overall effectiveness of the US Army.

The Advantages of Implementing a Right-to-Repair Policy within the US Army

A right-to-repair policy empowers the US Army to conduct more in-house maintenance, leading to numerous advantages:

- Faster repair times, leading to quicker equipment return to service: In-house repairs significantly reduce turnaround times, getting vital equipment back into operation faster.

- Cost savings through reduced reliance on external contractors: By performing more repairs in-house, the Army can significantly reduce its reliance on expensive external contractors, resulting in substantial cost reduction.

- Improved training opportunities for soldiers in maintenance and repair skills: A right-to-repair initiative allows soldiers to develop valuable maintenance and repair skills, enhancing their professional development and readiness. This enhanced training leads to greater soldier proficiency in army equipment repair.

- Enhanced supply chain resilience by reducing dependence on single sources for parts and repairs: In-house repair capabilities minimize dependence on single-source suppliers, safeguarding the Army against potential disruptions in the supply chain. This supply chain management strategy is vital for maintaining operational efficiency.

Implementing such a policy improves military efficiency and fosters a culture of self-sufficiency within the army, ultimately leading to significant cost savings and improved operational readiness.

Challenges and Obstacles to Implementing a Right-to-Repair Initiative

Transitioning to a right-to-repair model presents some challenges:

- Need for specialized training and equipment: Training soldiers in the complex skills required for specialized military repair necessitates significant investment in training programs and equipment.

- Potential risks of unauthorized repairs compromising equipment security: Robust security protocols and training are critical to mitigate the risks associated with unauthorized repairs.

- Balancing the need for independent maintenance with manufacturer warranties: Negotiating terms with manufacturers to maintain warranties while pursuing independent maintenance requires careful consideration.

- Negotiating access to repair manuals and parts: Securing access to necessary repair manuals and parts from manufacturers is a critical step in the implementation process.

Addressing these challenges through careful planning, strategic partnerships, and robust training programs is crucial for the successful implementation of an army right-to-repair initiative. This involves understanding the nuances of military security and intellectual property rights associated with military equipment.

Case Studies and Successful Implementations of Right-to-Repair in Similar Sectors

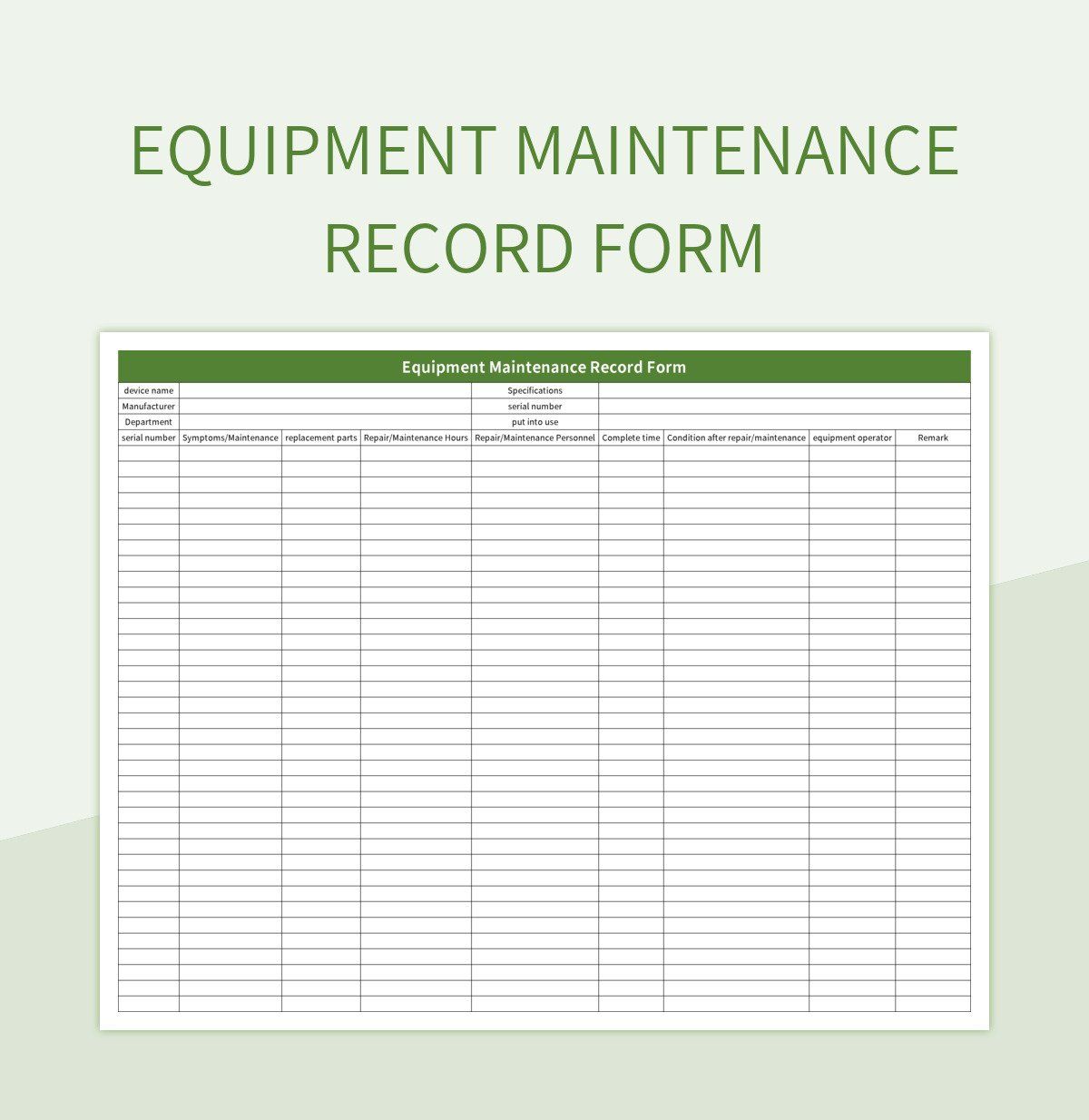

Several sectors have successfully implemented right-to-repair initiatives, providing valuable lessons for the US Army:

- Examples of companies implementing successful right-to-repair programs: Companies like Fairphone and iFixit have successfully incorporated right-to-repair principles into their business models. These examples showcase that right-to-repair success stories are achievable in various sectors.

- Quantifiable results demonstrating cost savings and increased efficiency: Studies show that right-to-repair programs have led to substantial cost savings and increased efficiency in various industries.

- Lessons learned from past implementations: Analyzing past implementations offers invaluable insights into best practices and potential pitfalls to avoid.

Studying these case studies provides valuable insights and best practices for the US Army's own right-to-repair initiative, demonstrating that it's a viable and beneficial strategy.

Conclusion: Embracing the Future of Military Maintenance with Right-to-Repair

Adopting a right-to-repair approach offers significant advantages for the US Army, including substantial cost savings, improved operational efficiency, and enhanced readiness. By embracing independent military repair and investing in soldier training, the Army can build a more resilient and cost-effective maintenance system. The future of military maintenance lies in empowering the Army with the knowledge and tools to maintain its own equipment. We urge further research and discussion on implementing a comprehensive right-to-repair policy to optimize military maintenance and ensure the continued operational effectiveness of the US Army. Let's work together to create a robust and sustainable system for army equipment repair.

Featured Posts

-

Cassidy Hutchinsons Memoir Key Jan 6 Witness To Share Her Story

May 18, 2025

Cassidy Hutchinsons Memoir Key Jan 6 Witness To Share Her Story

May 18, 2025 -

Billionaire Behind Air Trunk Acquires Second Sydney Property In Crown

May 18, 2025

Billionaire Behind Air Trunk Acquires Second Sydney Property In Crown

May 18, 2025 -

Identifying The Countrys Next Business Growth Areas

May 18, 2025

Identifying The Countrys Next Business Growth Areas

May 18, 2025 -

New Music Friday Ezra Furman Billy Nomates And Damiano David

May 18, 2025

New Music Friday Ezra Furman Billy Nomates And Damiano David

May 18, 2025 -

Damiano David Sparks Kaytranada Bilbao Bbk Live 2025 Lineup Expands

May 18, 2025

Damiano David Sparks Kaytranada Bilbao Bbk Live 2025 Lineup Expands

May 18, 2025

Latest Posts

-

Kanye Wests Funeral Instructions Inspired By Pasha Technik

May 18, 2025

Kanye Wests Funeral Instructions Inspired By Pasha Technik

May 18, 2025 -

Did They Split Kanye West And Bianca Censori Dine Together In Spain

May 18, 2025

Did They Split Kanye West And Bianca Censori Dine Together In Spain

May 18, 2025 -

Pokhorony Po Uestovski Vdokhnovenie Ot Pashi Tekhnikom

May 18, 2025

Pokhorony Po Uestovski Vdokhnovenie Ot Pashi Tekhnikom

May 18, 2025 -

Instruktsiya Kane Uesta K Sobstvennym Pokhoronam Vdokhnovenie Ot Pashi Tekhnikom

May 18, 2025

Instruktsiya Kane Uesta K Sobstvennym Pokhoronam Vdokhnovenie Ot Pashi Tekhnikom

May 18, 2025 -

Kanye West Bianca Censori Enjoy Dinner Date In Spain Amidst Relationship Speculation

May 18, 2025

Kanye West Bianca Censori Enjoy Dinner Date In Spain Amidst Relationship Speculation

May 18, 2025