Sustainable Steel: Eramet's EraLow And The Reduction Of CO2 Emissions In Steelmaking

Table of Contents

Understanding the Environmental Impact of Traditional Steelmaking

The Carbon Footprint of Conventional Steel Production

Traditional steel production, primarily reliant on blast furnaces, is an incredibly energy-intensive process. The blast furnace method, while effective, relies heavily on coking coal, a significant contributor to greenhouse gas emissions. The process involves:

- High-temperature operations: Maintaining the extremely high temperatures required for smelting iron ore consumes vast amounts of energy, often derived from fossil fuels.

- Coking coal dependence: Coking coal is used as a reducing agent, releasing substantial amounts of carbon dioxide (CO2) into the atmosphere. This contributes significantly to the overall carbon emissions of steel production.

- Significant energy consumption: The energy-intensive nature of blast furnaces leads to a large carbon footprint, impacting the environment.

These factors contribute to the substantial carbon emissions associated with conventional steel production, making it crucial to find more environmentally friendly alternatives. Keywords: carbon emissions, steel production, blast furnace, coking coal, greenhouse gases.

The Urgent Need for Green Steel Solutions

Global demand for steel continues to rise, driven by infrastructure development, construction, and industrial growth. This increasing demand exacerbates the environmental challenges associated with traditional steelmaking. Meeting international climate goals and achieving sustainable development requires a fundamental shift towards green steel solutions. The pressure is on the steel industry to decarbonize its processes and drastically reduce its environmental impact. Keywords: green steel, decarbonization, climate change, sustainable development, low-carbon steel.

Eramet's eraLow: A Breakthrough in Sustainable Steel Production

Introducing Eramet's eraLow Technology

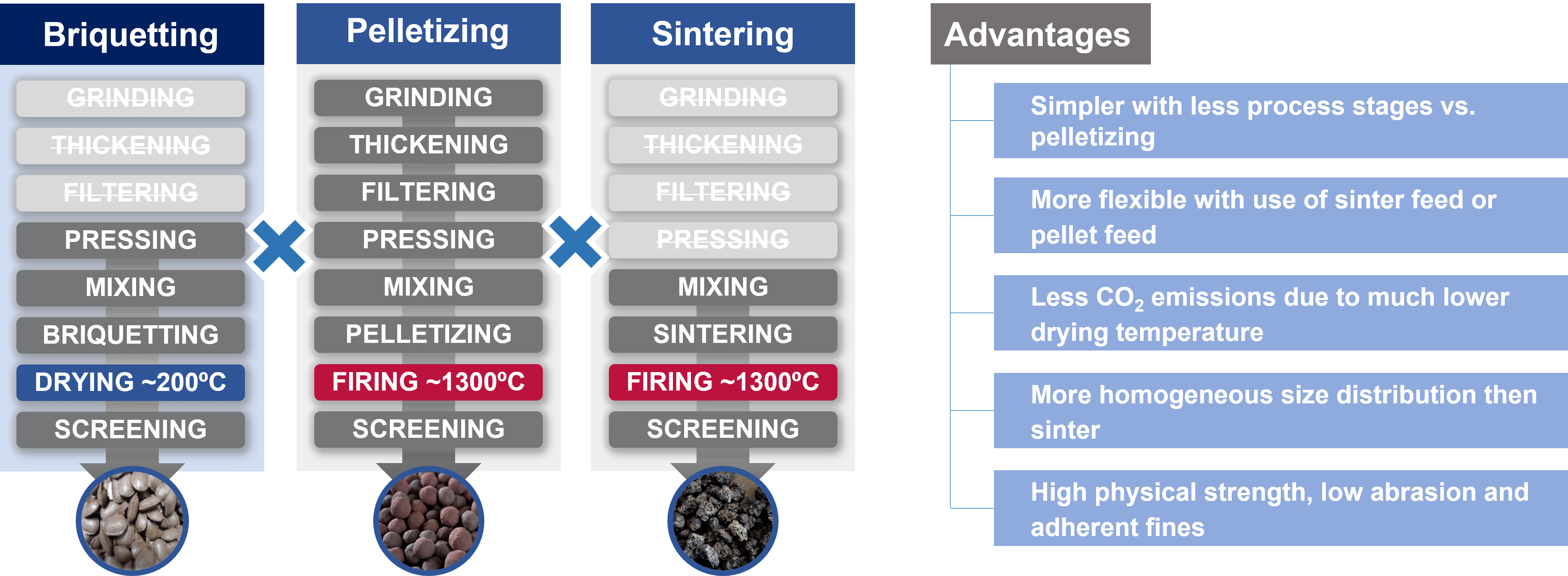

Eramet's eraLow technology represents a groundbreaking approach to sustainable steelmaking. It focuses on reducing reliance on coking coal by utilizing alternative raw materials and optimizing the smelting process. The core principles of eraLow include:

- Direct reduced iron (DRI): eraLow utilizes DRI, a pre-processed form of iron that significantly reduces the need for coking coal in the subsequent steelmaking steps.

- Hydrogen-based reduction: The process incorporates hydrogen, a cleaner energy source, in the reduction of iron ore, leading to lower CO2 emissions.

- Optimized energy use: eraLow employs innovative technologies to maximize energy efficiency throughout the steelmaking process.

This innovative approach makes eraLow a key player in low-carbon steel production and the broader sustainable steelmaking movement. Keywords: eraLow, sustainable steelmaking, low-carbon steel production, alternative raw materials.

Key Advantages of the eraLow Process

The eraLow process offers several compelling advantages over traditional methods:

- Reduced CO2 emissions: Eramet reports a substantial reduction in CO2 emissions compared to conventional blast furnace methods, contributing significantly to lower greenhouse gas emissions. Specific percentage reductions are available on Eramet’s website.

- Improved energy efficiency: The optimized process design leads to significant energy savings, reducing operational costs and environmental impact.

- Enhanced material properties: The eraLow process can potentially lead to improvements in the quality and performance characteristics of the resulting steel.

Keywords: CO2 reduction, energy efficiency, steel quality, sustainable manufacturing.

The Future of Sustainable Steel with Eramet's eraLow

Scalability and Future Potential of eraLow

Eramet is actively pursuing the scalability of the eraLow process, investing in research and development to increase production capacity. Future plans include:

- Expansion of production facilities: Eramet is actively working on expanding its eraLow facilities to meet the growing demand for sustainable steel.

- Strategic partnerships: Collaborations with other industry players are crucial for broader implementation and knowledge sharing.

- Technological advancements: Continuous improvements and technological advancements will further enhance the efficiency and sustainability of the eraLow process.

Keywords: scalability, industrial implementation, future technologies, collaboration.

The Role of Sustainable Steel in a Green Economy

Sustainable steel, produced through technologies like Eramet's eraLow, plays a crucial role in building a green economy. Its importance extends beyond reducing CO2 emissions; it contributes to:

- Circular economy initiatives: Sustainable steel production aligns with the principles of a circular economy, minimizing waste and maximizing resource utilization.

- Sustainable infrastructure development: The demand for sustainable materials in construction and infrastructure projects is ever-increasing, making sustainable steel essential for building a greener future.

- Meeting climate targets: The widespread adoption of sustainable steel production methods is paramount in achieving global climate targets and mitigating the effects of climate change.

Keywords: circular economy, sustainable infrastructure, green economy, climate targets.

Conclusion: Embracing Sustainable Steel with Eramet's eraLow

Eramet's eraLow technology offers a viable and impactful solution to reduce CO2 emissions in steelmaking. By leveraging alternative raw materials, optimizing energy use, and implementing innovative technologies, eraLow contributes significantly to the production of sustainable steel. The benefits extend beyond environmental considerations, encompassing economic advantages and improvements in material properties. Embracing sustainable steel practices like Eramet's eraLow is not just environmentally responsible; it's essential for building a sustainable future. Learn more about how Eramet's eraLow technology is revolutionizing sustainable steel production and contributing to a greener future. [Link to Eramet's website]

Featured Posts

-

Hl Tewd Sylyn Dywn Ila Msrh Ywrwfyjn Fy Bazl Akhbar Alkhlyj

May 14, 2025

Hl Tewd Sylyn Dywn Ila Msrh Ywrwfyjn Fy Bazl Akhbar Alkhlyj

May 14, 2025 -

Tom Cruise And Mission Impossible Dead Reckoning Part Two A Franchise Finale

May 14, 2025

Tom Cruise And Mission Impossible Dead Reckoning Part Two A Franchise Finale

May 14, 2025 -

Prestizhne Patike Novaka Okovi A Tsena I Karakteristike 1 500 Evra

May 14, 2025

Prestizhne Patike Novaka Okovi A Tsena I Karakteristike 1 500 Evra

May 14, 2025 -

Zegler Present Gadot Absent Snow White Spain Promotional Event

May 14, 2025

Zegler Present Gadot Absent Snow White Spain Promotional Event

May 14, 2025 -

Captain America Brave New World Now Streaming At Home

May 14, 2025

Captain America Brave New World Now Streaming At Home

May 14, 2025