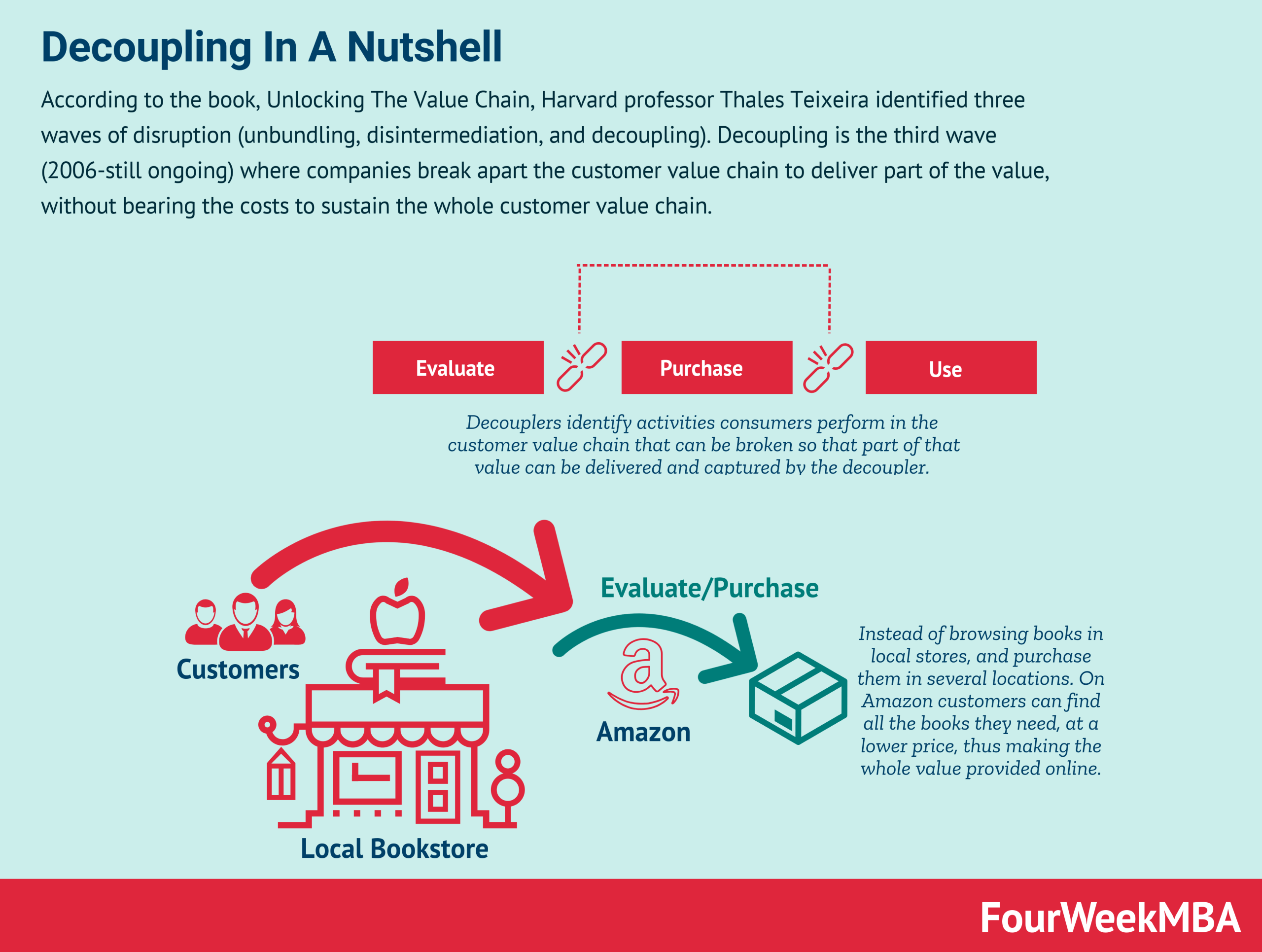

The Great Decoupling And Its Impact On Supply Chains

Table of Contents

Geopolitical Risks and the Rise of Regionalization

The increasing geopolitical instability and escalating trade wars are primary drivers of the Great Decoupling. Businesses are actively seeking to mitigate risks associated with over-reliance on single-source countries, opting instead for diversification across multiple regions. This strategic shift aims to reduce vulnerability to disruptions caused by various geopolitical factors.

- Increased tariffs and trade restrictions: The imposition of tariffs and trade restrictions by various governments creates uncertainty and significantly increases the cost of goods. Businesses are forced to re-evaluate their sourcing strategies to minimize the impact of these protectionist measures.

- Political instability and sanctions: Political instability and sanctions imposed on certain countries can lead to sudden disruptions in supply chains. Companies are increasingly prioritizing stability and predictability when selecting suppliers and manufacturing locations.

- Concerns over intellectual property theft: The risk of intellectual property theft in some regions pushes companies to seek alternative sourcing options that provide better protection for their innovations and trade secrets. This includes locating manufacturing closer to home or in trusted allied nations.

- Shift towards "friend-shoring" and "near-shoring": The concept of "friend-shoring," prioritizing partnerships with politically aligned countries, and "near-shoring," relocating production to geographically closer locations, are gaining significant traction as companies actively seek to shorten supply chains and reduce risk. Examples include reshoring manufacturing to North America, near-shoring to Mexico, and increased investment in Southeast Asia for companies seeking diversification away from China. This regionalization strategy aims to enhance resilience and reduce dependence on potentially unstable regions.

Pandemic-Induced Vulnerabilities and Supply Chain Resilience

The COVID-19 pandemic served as a stark reminder of the fragility of overly centralized and globalized supply chains. Widespread disruptions in manufacturing, logistics, and transportation exposed the critical need for greater resilience and diversification. The pandemic accelerated the adoption of strategies aimed at mitigating future risks.

- Port congestion and shipping delays: The pandemic exposed vulnerabilities in global shipping networks, resulting in significant port congestion and lengthy shipping delays, causing widespread supply shortages.

- Factory closures and labor shortages: Lockdowns and health restrictions led to factory closures and labor shortages in various regions, creating major bottlenecks in production and delivery.

- Increased reliance on digital supply chain management: The pandemic underscored the importance of digital technologies for monitoring, tracking, and managing supply chains. Companies invested heavily in digital tools to improve visibility and responsiveness.

- Emphasis on inventory management and buffer stocks: Many businesses realized the critical need to maintain higher levels of inventory to cushion against future disruptions. This shift towards "buffer stocking" is a key element of building more resilient supply chains.

Technological Advancements and Supply Chain Automation

The Great Decoupling is significantly accelerating the adoption of new technologies to enhance supply chain visibility, efficiency, and responsiveness. Automation, artificial intelligence (AI), and blockchain technology are playing a crucial role in adapting to the new landscape and building more robust and agile supply chains.

- Increased use of AI-powered demand forecasting: AI-powered tools are used for more accurate demand forecasting, enabling businesses to optimize inventory levels and avoid stockouts or overstocking.

- Implementation of blockchain for improved traceability: Blockchain technology enhances traceability and transparency throughout the supply chain, improving accountability and reducing counterfeiting risks.

- Automation of warehousing and logistics processes: Automation of warehousing and logistics processes, including robotics and automated guided vehicles (AGVs), improves efficiency and reduces labor costs.

- Adoption of digital twins for supply chain modeling: Digital twins provide virtual representations of supply chains, allowing businesses to test different scenarios and optimize their networks for greater resilience.

The Role of Sustainability in Decoupled Supply Chains

The Great Decoupling presents a unique opportunity to build more sustainable and ethical supply chains. Companies are increasingly prioritizing environmental, social, and governance (ESG) factors when selecting suppliers and designing their networks.

- Reduced carbon emissions through regionalization: Regionalization can lead to reduced carbon emissions by shortening transportation distances and minimizing the environmental impact of global shipping.

- Improved labor standards and ethical sourcing: Companies are increasingly scrutinizing labor practices and ethical sourcing in their supply chains, ensuring fair wages, safe working conditions, and responsible sourcing of materials.

- Increased transparency and traceability: Improved transparency and traceability throughout the supply chain enhances accountability and enables companies to better address social and environmental issues.

- Sustainable packaging and waste reduction: Companies are adopting sustainable packaging and waste reduction strategies to minimize their environmental footprint.

Conclusion

The Great Decoupling represents a profound shift in global supply chain strategies. While it presents considerable challenges, such as increased costs and complexity, it also unlocks opportunities for enhanced resilience, sustainability, and regional economic development. By strategically embracing technological advancements, diversifying supplier bases, and proactively implementing robust risk management strategies, businesses can successfully navigate this evolving landscape and build more resilient and competitive supply chains. To thrive in this new era, a deep understanding of the Great Decoupling and proactive adaptation are paramount. Learn more about managing your supply chain in the age of the Great Decoupling and discover best practices for building a resilient and efficient network. Mastering the challenges of the Great Decoupling will be crucial for future success.

Featured Posts

-

Dieu Tra Va Xu Ly Vu Bao Hanh Tre Em Tai Tien Giang

May 09, 2025

Dieu Tra Va Xu Ly Vu Bao Hanh Tre Em Tai Tien Giang

May 09, 2025 -

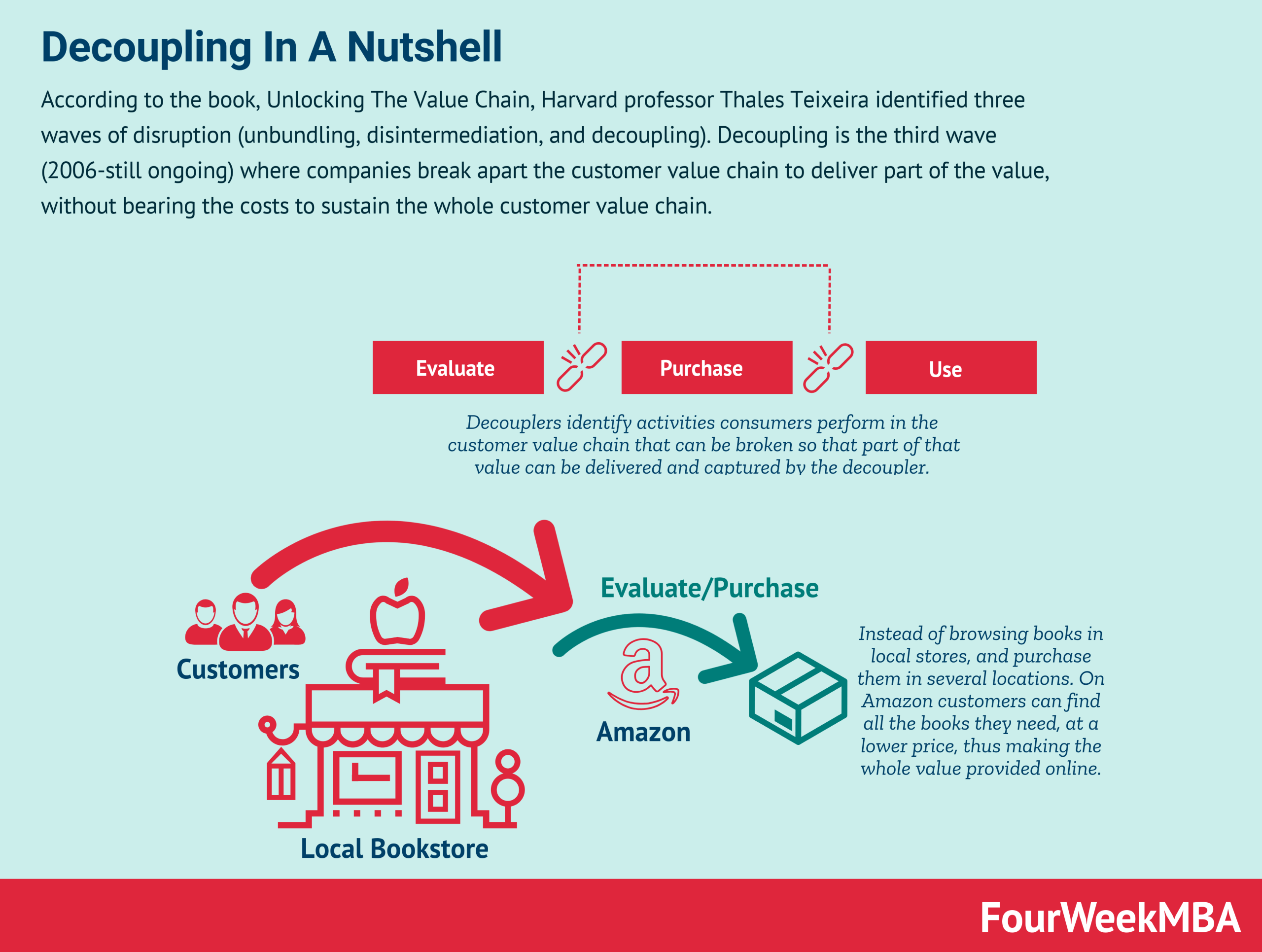

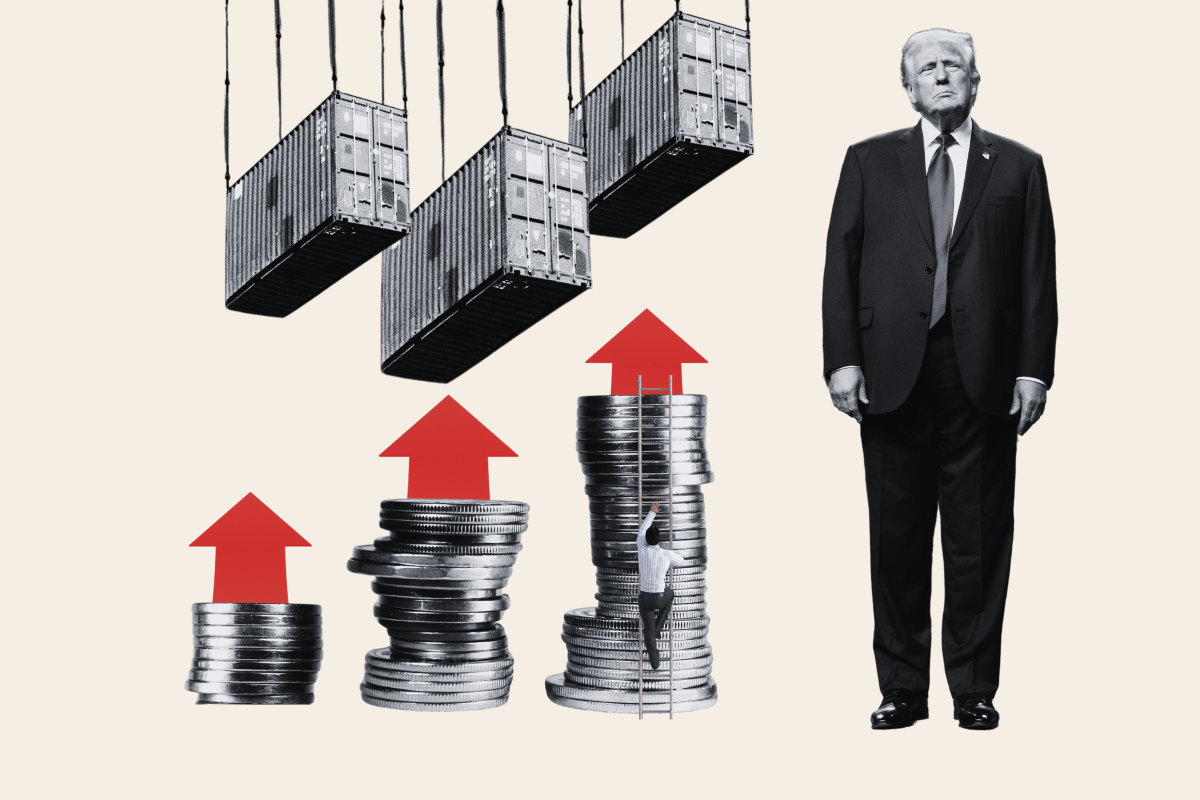

Trumps Billionaire Friends How Tariffs Impacted Their Fortunes After Liberation Day

May 09, 2025

Trumps Billionaire Friends How Tariffs Impacted Their Fortunes After Liberation Day

May 09, 2025 -

F1 Update Alpine Bosss Direct Message To Doohan

May 09, 2025

F1 Update Alpine Bosss Direct Message To Doohan

May 09, 2025 -

The Economic Fallout How Tariffs Affected Donald Trumps Billionaire Circle After Liberation Day

May 09, 2025

The Economic Fallout How Tariffs Affected Donald Trumps Billionaire Circle After Liberation Day

May 09, 2025 -

Sinoptiki I Mayskie Snegopady Pochemu Prognozy Tak Slozhny

May 09, 2025

Sinoptiki I Mayskie Snegopady Pochemu Prognozy Tak Slozhny

May 09, 2025

Latest Posts

-

14 Edmonton Area School Projects Accelerated Timeline Announced

May 09, 2025

14 Edmonton Area School Projects Accelerated Timeline Announced

May 09, 2025 -

Betting On The Oilers Kings Series Odds And Expert Analysis

May 09, 2025

Betting On The Oilers Kings Series Odds And Expert Analysis

May 09, 2025 -

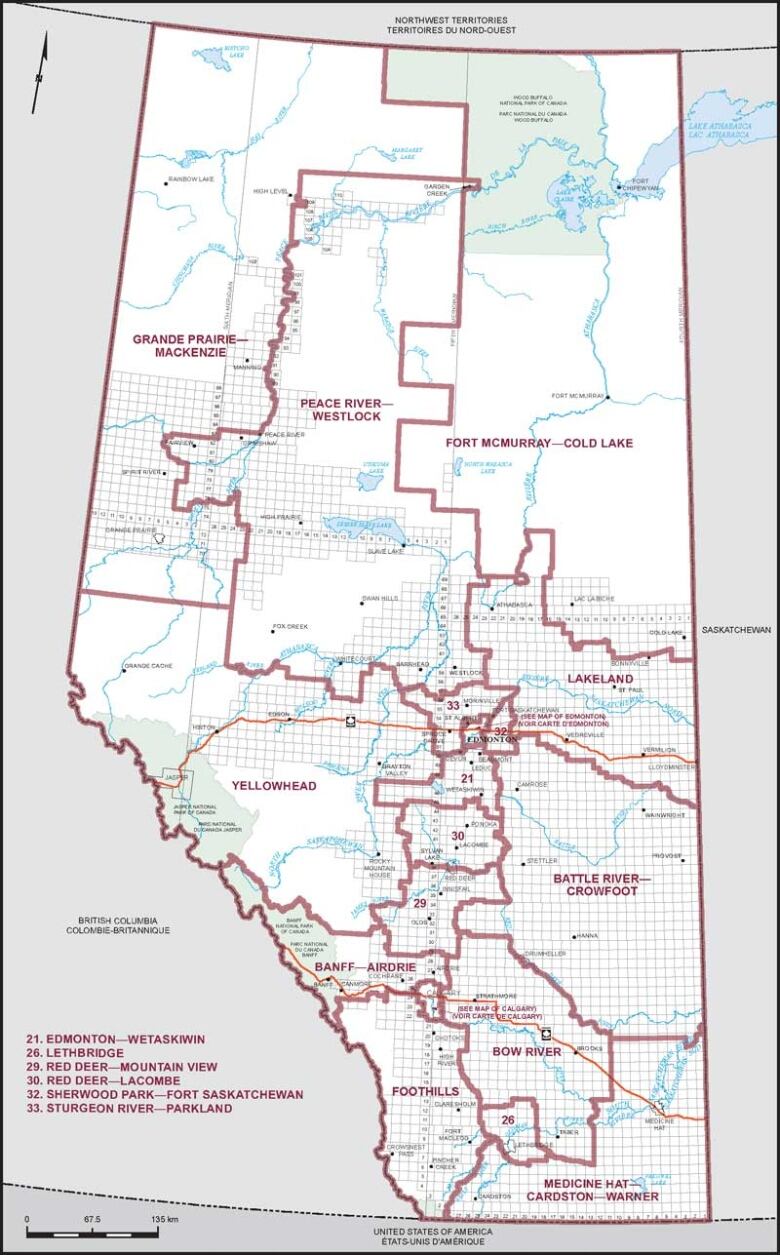

Greater Edmontons New Federal Ridings A Voters Guide

May 09, 2025

Greater Edmontons New Federal Ridings A Voters Guide

May 09, 2025 -

Nhl Playoffs Edmonton Oilers Betting Odds To Eliminate Kings

May 09, 2025

Nhl Playoffs Edmonton Oilers Betting Odds To Eliminate Kings

May 09, 2025 -

How Federal Riding Redistribution Will Impact Edmonton Voters

May 09, 2025

How Federal Riding Redistribution Will Impact Edmonton Voters

May 09, 2025