Trump's Tariffs: Automakers Struggle With Uncertainty

Table of Contents

Increased Costs and Reduced Profit Margins

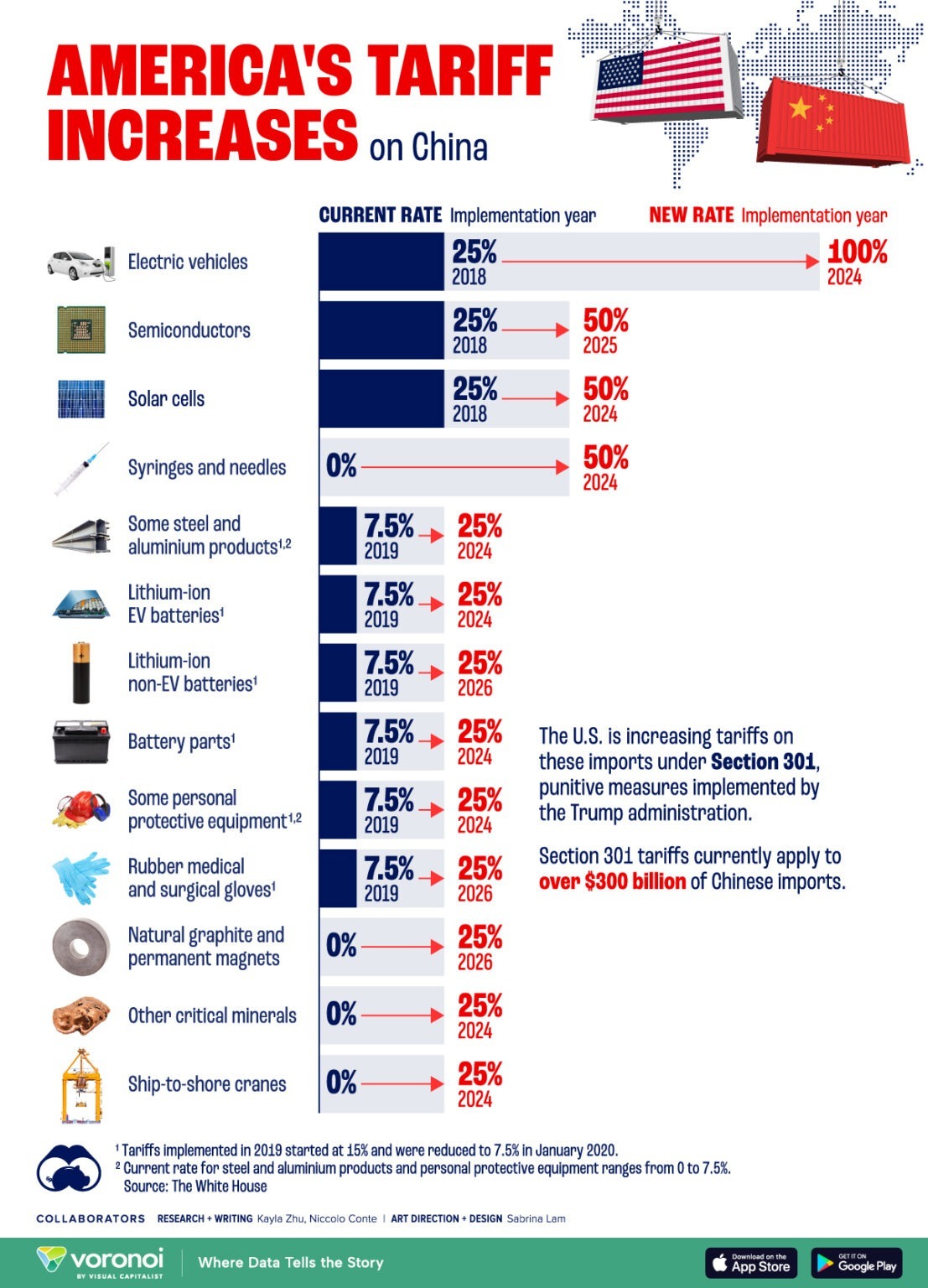

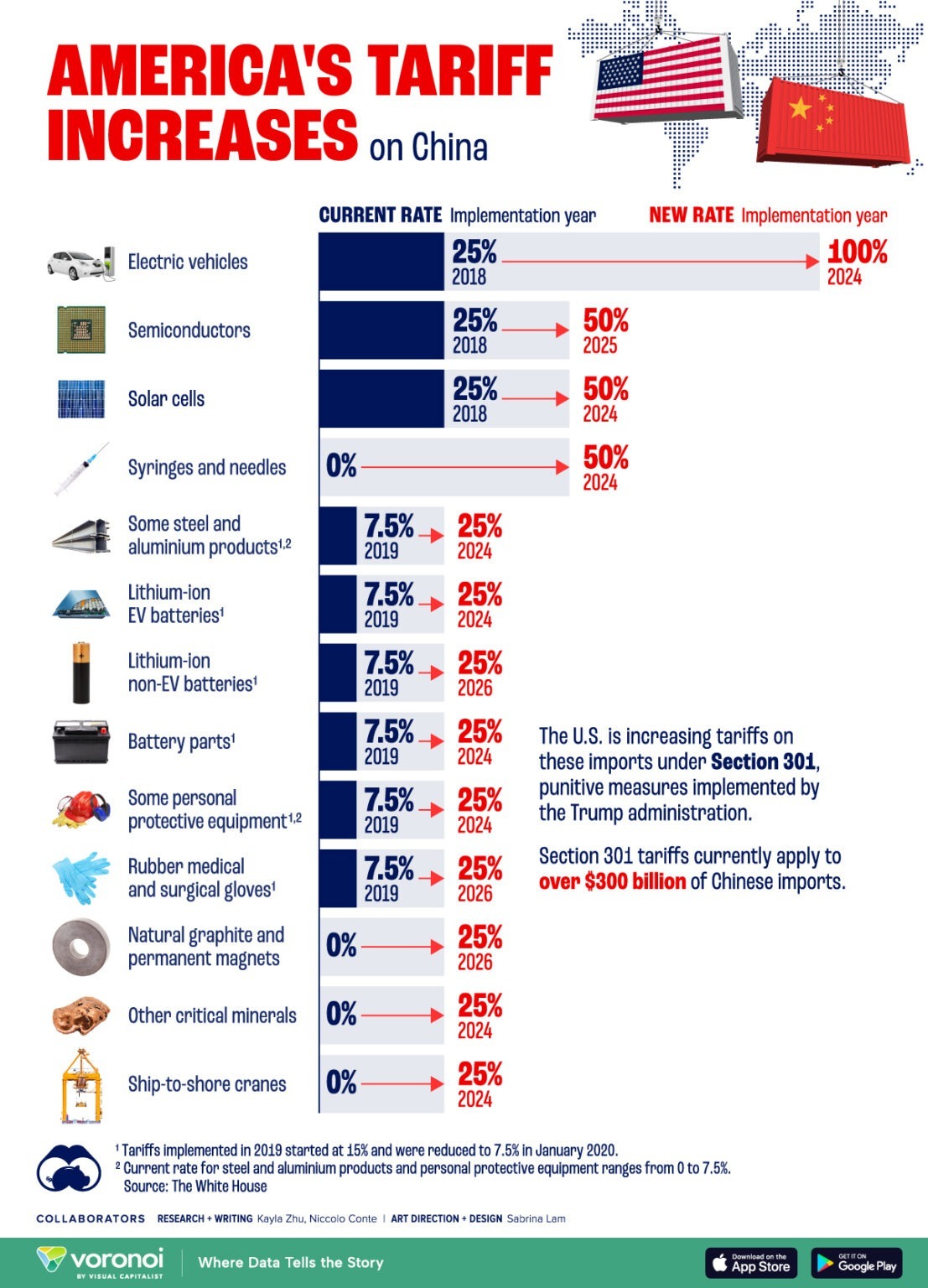

Trump's tariffs dramatically increased the cost of imported parts and materials, directly squeezing profit margins for automakers. The imposition of duties on steel and aluminum, key components in vehicle production, led to a domino effect throughout the supply chain.

- Higher steel and aluminum prices directly impacted vehicle production costs. The increased cost of raw materials translated directly into higher manufacturing expenses.

- Increased costs were difficult to pass on to consumers due to market competition. Automakers faced a challenging dilemma: absorb the increased costs and reduce profitability or pass them onto consumers, risking a decrease in sales in a competitive market.

- Reduced profitability forced automakers to explore cost-cutting measures. This led to difficult decisions, including potential job cuts, reduced investment in research and development, and streamlining of operations.

For example, the price increases for steel alone forced several automakers to re-evaluate their production strategies and absorb millions of dollars in additional expenses. This resulted in reduced quarterly profits and a dampening of investment plans for future models.

Supply Chain Disruptions and Production Delays

The tariffs didn't just impact costs; they also severely disrupted global supply chains, causing delays and shortages of essential parts. The complexity of modern automotive manufacturing relies on a global network of suppliers. Trump's tariffs threw a wrench into this intricate system.

- Tariffs led to delays in importing parts from countries affected by the tariffs. This created bottlenecks in the production process, halting or slowing down assembly lines.

- Automakers were forced to seek alternative suppliers, often at a higher cost. Finding new suppliers required significant time and resources, further impacting efficiency and cost.

- Production schedules were disrupted, leading to decreased output and potential revenue losses. The cascading effect of delays throughout the supply chain resulted in significant financial repercussions for automakers.

Several major automakers reported significant production delays due to the unavailability of specific parts resulting from the tariffs. These delays translated into lost sales and damaged brand reputation.

Impact on Consumer Prices and Demand

The increased production costs stemming from Trump's tariffs ultimately translated into higher vehicle prices, potentially influencing consumer demand. This economic impact rippled through the entire automotive market.

- Increased production costs led to higher sticker prices for new vehicles. Automakers passed some of the increased expenses onto consumers, making vehicles more expensive.

- Higher prices reduced consumer purchasing power and potentially dampened demand. In a price-sensitive market, higher prices can lead to consumers delaying purchases or opting for used vehicles.

- The impact on consumer demand varied depending on the vehicle segment and market. Luxury car segments might be less affected by price increases compared to budget-friendly vehicle segments.

Economic data from the period showed a clear correlation between the imposition of tariffs and a slight but measurable decrease in new vehicle sales in certain market segments.

Political and Geopolitical Ramifications

Trump's tariffs extended beyond economic consequences, triggering broader political and geopolitical ramifications within the international trade landscape. The actions triggered retaliatory measures and heightened trade tensions.

- Escalation of trade disputes with other countries. The tariffs ignited a trade war, with other nations imposing their own retaliatory tariffs on US goods.

- Retaliatory tariffs imposed by other nations on US auto exports. This created a challenging environment for US automakers trying to compete in international markets.

- Uncertainty regarding future trade policies and their impact on the auto industry. The unpredictable nature of trade policies created instability and made long-term planning difficult.

Adaptation Strategies of Automakers

Faced with these considerable challenges, automakers responded with a variety of adaptation strategies:

- Restructuring supply chains to reduce reliance on tariff-affected countries. This involved sourcing parts from alternative regions and diversifying supplier networks.

- Investing in domestic production and sourcing of materials. Automakers increased investments in domestic manufacturing to reduce reliance on imports.

- Lobbying efforts to influence trade policy and mitigate the impact of tariffs. Auto industry groups actively lobbied policymakers to address the negative consequences of the tariffs.

Conclusion: Understanding the Long-Term Effects of Trump's Tariffs on Automakers

Trump's tariffs presented significant challenges to automakers, resulting in increased costs, supply chain disruptions, higher consumer prices, and heightened geopolitical tensions. The lasting impact on the industry's profitability, production, and global competitiveness is undeniable. These tariffs served as a stark reminder of the interconnectedness of global trade and the vulnerability of industries reliant on complex international supply chains. Understanding the complexities of Trump's tariffs and their ripple effect is crucial. Continue your research into the long-term effects of these tariffs on the auto industry and other sectors to stay informed about the ever-evolving landscape of global trade.

Featured Posts

-

Play Station Plus Extra And Premium July 2024 Game Lineup Revealed

May 02, 2025

Play Station Plus Extra And Premium July 2024 Game Lineup Revealed

May 02, 2025 -

Us Sales Showdown Ps 5 Vs Xbox Series X S Which Console Reigns Supreme

May 02, 2025

Us Sales Showdown Ps 5 Vs Xbox Series X S Which Console Reigns Supreme

May 02, 2025 -

New Insights Into Rarely Seen Seabirds Research By Te Ipukarea Society

May 02, 2025

New Insights Into Rarely Seen Seabirds Research By Te Ipukarea Society

May 02, 2025 -

Aleab Blay Styshn 6 Almntzrt

May 02, 2025

Aleab Blay Styshn 6 Almntzrt

May 02, 2025 -

Promoting Mental Wellness 5 Ways To Foster Acceptance In Your Community

May 02, 2025

Promoting Mental Wellness 5 Ways To Foster Acceptance In Your Community

May 02, 2025