U.S. Electric Motor Development: Countering China's Influence

Table of Contents

The Current State of U.S. Electric Motor Manufacturing

Production Capacity and Market Share

The U.S. currently holds a significantly smaller share of the global electric motor market compared to China. While precise figures fluctuate, estimates suggest that China's production dwarfs that of the U.S. by a considerable margin. This disparity stems from several interconnected factors:

- Lower Labor Costs: China's lower labor costs provide a significant competitive advantage in manufacturing.

- Established Supply Chains: China boasts a mature and integrated supply chain for electric motor components, reducing production lead times and costs.

- Government Subsidies: Government support and incentives in China have fueled rapid growth in their electric motor industry.

- Economies of Scale: China's massive production volume allows for economies of scale, further reducing costs.

Importantly, the U.S. currently imports a substantial portion of its electric motor needs, highlighting a crucial vulnerability in our domestic supply chain. Data from [Insert Source: e.g., U.S. Census Bureau] shows that [Insert Specific Import/Export Data]. This reliance on foreign suppliers presents a significant risk to national security and economic stability.

Technological Advancements in U.S. Electric Motor Design

Despite the challenges, U.S. researchers and engineers are making significant strides in electric motor technology. Several promising areas include:

- High-Efficiency Motors: Developments in permanent magnet motors and switched reluctance motors are leading to significant improvements in energy efficiency.

- Advanced Materials: The use of lightweight, high-strength materials like carbon fiber and advanced composites is improving motor performance and reducing weight.

- Motor Control Systems: Advanced control algorithms and digital signal processors are optimizing motor performance and extending operational lifespan.

These innovations, often supported by government grants through agencies like ARPA-E and university partnerships, represent a crucial foundation for future growth in U.S. electric motor development.

Supply Chain Vulnerabilities

The U.S. electric motor industry faces significant supply chain vulnerabilities, heavily reliant on foreign sources for critical raw materials and components, particularly from China. These vulnerabilities include:

- Rare Earth Elements: China dominates the global supply of rare earth elements crucial for the production of high-performance permanent magnet motors.

- Electronic Components: A significant portion of electronic components used in motor control systems are sourced from China.

- Manufacturing Expertise: Specialized manufacturing processes and expertise are concentrated in certain regions, leading to potential bottlenecks.

These dependencies create significant risks, including potential disruptions to production due to geopolitical instability or trade disputes.

Strategies for Countering China's Influence

Investing in Domestic Manufacturing

Revitalizing U.S. electric motor manufacturing requires significant investment in facilities and infrastructure. This can be achieved through:

- Government Incentives: Tax credits, grants, and loan guarantees can incentivize domestic production and attract investment.

- Infrastructure Development: Investment in advanced manufacturing facilities and skilled workforce training programs is essential.

- Strategic Partnerships: Public-private partnerships can leverage the strengths of both sectors, accelerating innovation and deployment.

Targeted incentives focused on specific geographic regions could stimulate growth in economically depressed areas.

Strengthening Research and Development

Increased investment in R&D is critical for maintaining a technological edge in electric motor technology. This includes:

- Funding Research Initiatives: Increased government funding for basic and applied research in areas like advanced materials and motor control systems is crucial.

- University-Industry Collaboration: Strengthening partnerships between universities, national labs, and private companies fosters innovation and talent development.

- Attracting and Retaining Talent: Investing in STEM education and creating attractive career pathways for engineers and scientists is vital.

The U.S. must prioritize attracting and retaining top talent in this field, offering competitive salaries and research opportunities.

Promoting Supply Chain Resilience

Diversifying the supply chain is paramount to reducing reliance on China. This involves:

- Friend-Shoring: Strengthening partnerships with trusted allies to establish alternative supply chains.

- Reshoring: Bringing manufacturing processes back to the U.S. to reduce reliance on foreign suppliers.

- Exploring Alternative Sources: Identifying and developing alternative sources for critical raw materials and components.

- Strategic Stockpiling: Building strategic reserves of crucial materials to mitigate supply disruptions.

These strategies will create a more robust and resilient supply chain, safeguarding the U.S. electric motor industry from geopolitical risks.

Enhancing National Security Measures

The national security implications of relying on China for critical technologies cannot be overstated. Strengthening national security measures requires:

- Export Controls: Implementing stricter export controls on technologies that could enhance China's electric motor capabilities.

- Targeted Sanctions: Imposing targeted sanctions on Chinese companies engaged in unfair trade practices or intellectual property theft.

- Investment Screening: Scrutinizing foreign investments in U.S. electric motor companies to prevent technology transfer to adversaries.

These measures are crucial to protecting U.S. national security interests in this strategically important sector.

Conclusion: The Future of U.S. Electric Motor Development

The future of U.S. electric motor development hinges on addressing the challenges posed by China's dominance and proactively implementing the strategies outlined above. By investing in domestic manufacturing, strengthening R&D, promoting supply chain resilience, and enhancing national security measures, the U.S. can secure its position in this critical technology sector. Investing in U.S. electric motor development is critical for national security and economic competitiveness. Learn more about how you can support this vital industry and advocate for policies that prioritize U.S. electric motor development and technological leadership.

Featured Posts

-

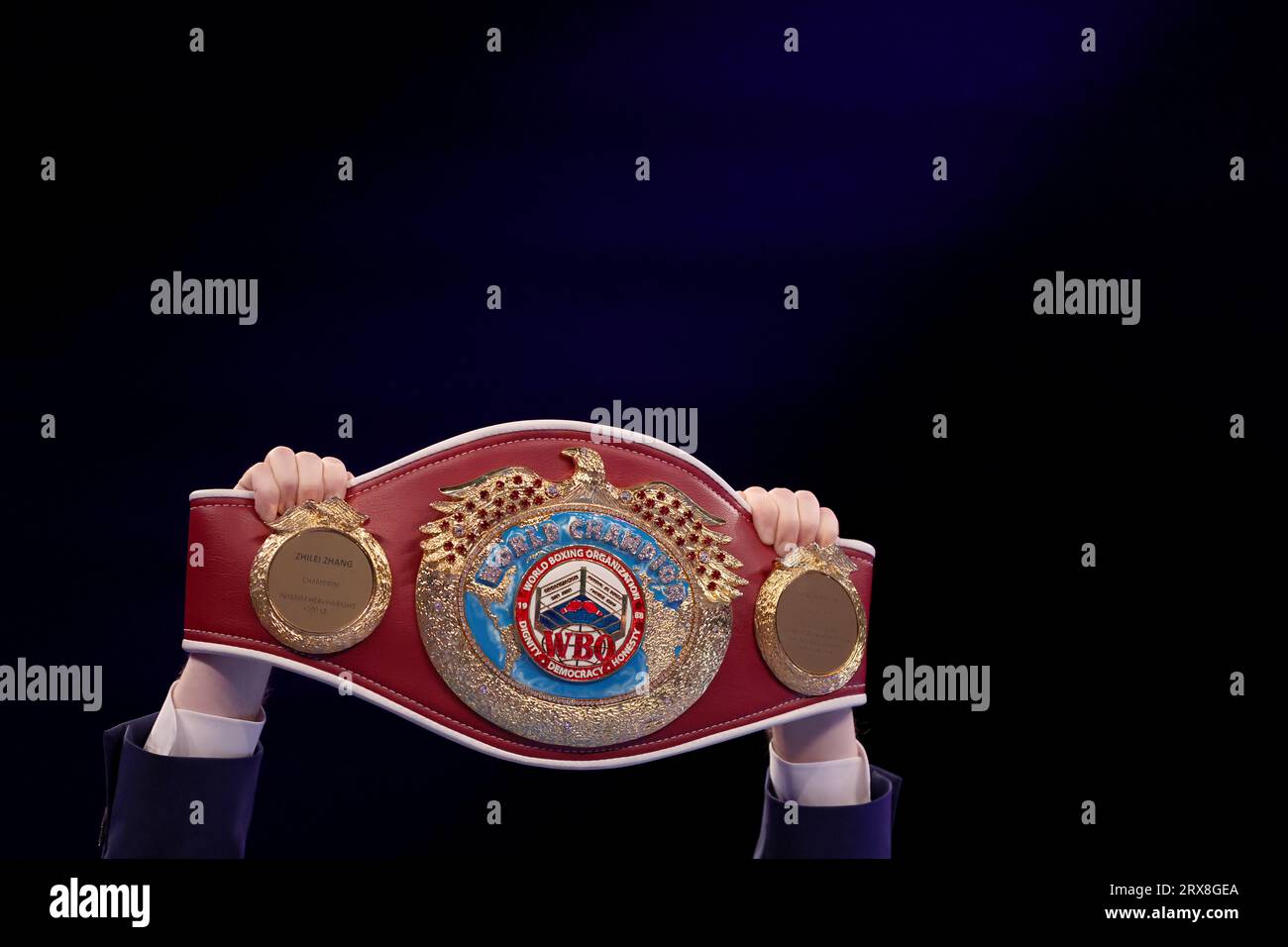

Parker Vs Bakole Interim Wbo Belt At Stake

May 04, 2025

Parker Vs Bakole Interim Wbo Belt At Stake

May 04, 2025 -

Ufc Des Moines Fight Night Mma Best Bets And Analysis

May 04, 2025

Ufc Des Moines Fight Night Mma Best Bets And Analysis

May 04, 2025 -

Turning Poop Into Prose An Ai Powered Podcast Revolution

May 04, 2025

Turning Poop Into Prose An Ai Powered Podcast Revolution

May 04, 2025 -

Berlangas Path To Glory Taking On Plant Munguia And Charlo

May 04, 2025

Berlangas Path To Glory Taking On Plant Munguia And Charlo

May 04, 2025 -

In Real Life Tour A Guide To Lizzo Ticket Prices

May 04, 2025

In Real Life Tour A Guide To Lizzo Ticket Prices

May 04, 2025