Why Robots Struggle To Create Nike Shoes: Technological Hurdles

Table of Contents

Dexterity and Precision: The Problem of Fine Motor Skills

Creating a Nike shoe requires a surprising level of dexterity and precision. The intricate hand-eye coordination and fine motor skills involved in tasks like stitching, gluing, and attaching complex components are far beyond the capabilities of most current robotic systems. Robots simply lack the finesse needed for these delicate operations.

- Manipulating Delicate Materials: The challenge of manipulating delicate materials like leather, suede, and various fabrics with robotic precision is immense. The softness and flexibility of these materials require a level of sensitivity that current robotic grippers struggle to replicate.

- Handling Diverse Shapes and Sizes: Shoe components come in a wide array of shapes and sizes. Adapting robotic systems to handle these variations reliably is a major obstacle. A robot that can precisely place a small buckle might struggle to handle a larger, irregularly shaped piece of sole material.

- Limitations of Robotic Grippers: Current robotic grippers often lack the adaptability needed to securely grasp and manipulate a variety of shoe components without damage. Advanced gripper designs are being developed, but widespread adoption remains some way off.

- The Need for Advanced Sensors: For robots to truly mimic human dexterity, they need advanced sensor technology that allows them to "feel" the materials they are working with. This "haptic feedback" is crucial for precise manipulation and quality control.

Adaptability and Flexibility: The Challenge of Variation

Nike constantly releases new shoe models, each with unique designs, sizes, and materials. This inherent variation poses a significant challenge for robotic automation. Robots are typically programmed for specific tasks and struggle to adapt to new situations without extensive reprogramming.

- Reprogramming for Each New Model: Reprogramming robots for each new shoe model is time-consuming, expensive, and inefficient. This process requires specialized expertise and often leads to production delays.

- Lack of Adaptable Robotic Systems: The current lack of truly adaptable robotic systems that can seamlessly switch between different tasks and shoe models is a major hurdle. Developing such systems requires significant advancements in AI and robotics.

- High Costs of Custom Solutions: Creating custom robotic solutions for each individual shoe type is prohibitively expensive for most manufacturers. The cost of development, implementation, and maintenance outweighs the potential benefits for many companies.

- The Role of AI and Machine Learning: AI and machine learning are crucial for creating more adaptable robots. By enabling robots to learn and adapt to new situations, these technologies could significantly improve the efficiency of automated shoe production.

Material Handling and Quality Control: Ensuring Consistent Results

Efficient material handling and robust quality control are essential for high-volume shoe production. Automating these processes for Nike shoes presents significant technical challenges.

- Consistent Material Feeding: Consistently feeding diverse materials into robotic systems is difficult. Variations in material shape, size, and texture can disrupt the automated process.

- Ensuring Product Quality: Maintaining consistent quality in automated shoe production is critical. This includes ensuring precise stitching, gluing, and the overall structural integrity of the finished product.

- High-Speed Quality Control: Implementing effective quality control measures in a high-speed automated environment requires advanced vision systems and sophisticated algorithms to detect defects quickly and accurately.

- Advanced Vision Systems for Inspection: Advanced vision systems are needed to inspect the shoes for defects, ensuring that only high-quality products leave the production line.

The Cost Factor: Balancing Automation with Economics

The high cost of developing and implementing sophisticated robotic systems for shoemaking often outweighs the benefits, especially considering the complexity of Nike's diverse product line and the need for high levels of precision and adaptability. The return on investment for full automation remains uncertain in many cases.

Conclusion

Why robots struggle to create Nike shoes boils down to a combination of factors: the need for exceptional dexterity and precision, the challenges of adapting to diverse shoe designs and materials, the difficulties of material handling and quality control, and the significant cost of implementation. While robotic automation in manufacturing is advancing rapidly, creating a Nike shoe remains a complex problem. Future advancements in AI, sensor technology, and robotic dexterity will be crucial for overcoming these technological hurdles. Understanding why robots struggle to create Nike shoes highlights the continued need for innovation in robotics and automation. Stay tuned for future breakthroughs in addressing the technological hurdles preventing fully automated shoe production!

Featured Posts

-

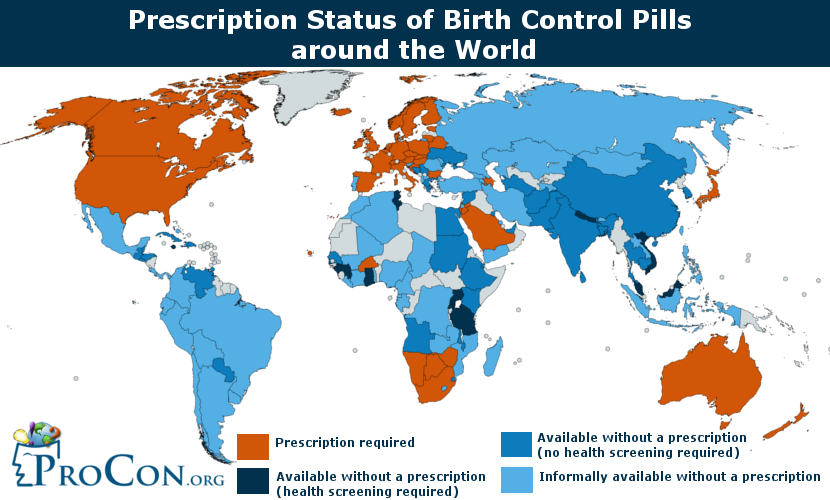

The Future Of Family Planning Otc Birth Control In A Post Roe World

Apr 22, 2025

The Future Of Family Planning Otc Birth Control In A Post Roe World

Apr 22, 2025 -

The Countrys Top New Business Locations A Comprehensive Map

Apr 22, 2025

The Countrys Top New Business Locations A Comprehensive Map

Apr 22, 2025 -

The Death Of Pope Francis A Global Loss

Apr 22, 2025

The Death Of Pope Francis A Global Loss

Apr 22, 2025 -

Chainalysis Acquires Alterya Blockchain Meets Ai

Apr 22, 2025

Chainalysis Acquires Alterya Blockchain Meets Ai

Apr 22, 2025 -

Why Middle Managers Are Essential For Company Success

Apr 22, 2025

Why Middle Managers Are Essential For Company Success

Apr 22, 2025