$70 Million Blow: Auto Carrier's Port Fee Predicament In The US

Table of Contents

Understanding the Structure of US Port Fees

Navigating the labyrinthine world of US port fees can be daunting. Auto carriers face a complex array of charges, significantly impacting their bottom line. Understanding the breakdown of these fees is the first step towards effective cost management.

A Breakdown of Fees

Several key fee categories contribute to the overall cost burden:

- Terminal Handling Charges (THC): These charges cover the handling of cargo at the terminal, including loading, unloading, and storage within the terminal facility. These fees vary significantly depending on the port, the type of cargo, and the volume.

- Chassis Fees: These fees relate to the use of chassis – specialized trailers used to transport vehicles. Charges can be incurred for pickup, drop-off, and any necessary repairs.

- Storage Fees: Delays at the port, often due to congestion, result in substantial storage fees. These fees accumulate daily, quickly escalating the overall cost.

- Detention Fees: Similar to storage fees, detention fees are levied when containers or vehicles are not picked up within a specified timeframe.

- Other Fees: Numerous other fees can arise, including documentation fees, customs clearance fees, and security fees.

Examples of Fee Structures:

- THC can range from $500 to $1,500 per container, depending on the port and size.

- Chassis fees can be $50-$150 per day.

- Storage fees average $50-$100 per day per vehicle.

Variations across US ports are significant, making it crucial for auto carriers to understand the specific fee structures at their chosen ports of entry. This necessitates detailed research and potentially negotiating agreements with individual port authorities.

The Impact of Port Congestion on Auto Carriers

Port congestion is a major exacerbating factor driving up costs for auto carriers. Delays at US ports translate directly into increased expenses and operational disruptions.

Increased Dwell Time and Costs

Congestion leads to significantly increased dwell time – the time a vehicle spends at the port waiting to be processed. This extended dwell time results in:

- Higher Storage Fees: The longer a vehicle sits in storage, the higher the accumulated storage fees.

- Increased Detention Fees: Delays inevitably lead to exceeding the allowed free time, triggering significant detention charges.

- Potential for Damage: Prolonged port stays increase the risk of vehicle damage due to weather exposure or potential accidents within the congested port environment.

Consequences of Delays:

- Missed Delivery Deadlines: Delays ripple through the supply chain, impacting downstream operations and potentially leading to penalties for missed deadlines.

- Reputational Harm: Consistent delays can damage an auto carrier's reputation, impacting future business opportunities.

- Increased Insurance Costs: The higher risk of damage associated with congestion can lead to increased insurance premiums.

Strategies for Mitigating Port Fee Costs

Effectively managing US port fees requires a proactive and multi-faceted approach, combining negotiation, logistical optimization, and technological solutions.

Negotiating with Port Authorities

High-volume auto carriers may be able to negotiate lower fees with port authorities. This requires demonstrating long-term commitment and a significant volume of cargo.

Optimizing Logistics and Planning

Strategic planning can minimize dwell time and, consequently, associated costs:

- Improved Scheduling: Meticulous scheduling ensures timely arrival and departure, minimizing storage and detention fees.

- Efficient Cargo Handling: Streamlined processes for loading, unloading, and documentation can significantly reduce port time.

- Strategic Port Selection: Choosing less congested ports, even if slightly further, can reduce overall costs.

Utilizing Technology and Data Analytics

Technology plays a crucial role in optimizing port fee management:

- Real-time Tracking: Real-time tracking of vehicles allows for proactive adjustments to schedules and improved communication with port authorities.

- Predictive Modeling: Data-driven predictive modeling can help anticipate potential delays and allow for proactive adjustments to prevent costly delays.

- Data Analytics: Analyzing historical port fee data can reveal patterns and help identify areas for improvement.

Actionable Steps:

- Implement a Transportation Management System (TMS) to optimize scheduling and tracking.

- Invest in real-time port congestion monitoring tools.

- Collaborate with port authorities to improve communication and transparency.

The Broader Economic Implications of High Port Fees

The impact of high US port fees extends far beyond auto carriers, affecting the entire automotive industry and the broader US economy.

Impact on Vehicle Prices

Increased port fees are ultimately passed on to consumers in the form of higher vehicle prices. This can impact affordability and potentially reduce consumer demand.

Effects on the US Automotive Industry

High port fees diminish the competitiveness of the US automotive industry on the global stage, impacting job creation and economic growth. This can lead to reduced investment in domestic manufacturing and a potential shift of production to countries with lower port fees.

Statistical Data (Illustrative):

- A hypothetical 10% increase in port fees could translate to a $X increase in the average price of a new vehicle.

- Increased port fees can contribute to a Y% decrease in the competitiveness of US automakers compared to global rivals.

Conclusion

The $70 million loss suffered by the auto carrier serves as a stark reminder of the substantial financial burden imposed by US port fees. These fees, exacerbated by port congestion, significantly impact auto carriers, the automotive industry, and the US economy as a whole. However, by understanding the structure of these fees, optimizing logistics, leveraging technology, and engaging in proactive negotiation, auto carriers can significantly reduce their exposure to these costs. Don't let high US port fees cripple your business. Take control of your automotive shipping costs today. Explore resources on supply chain management and port fee optimization to master US port fee management and reduce your US port fees. Start optimizing your automotive shipping costs now!

Featured Posts

-

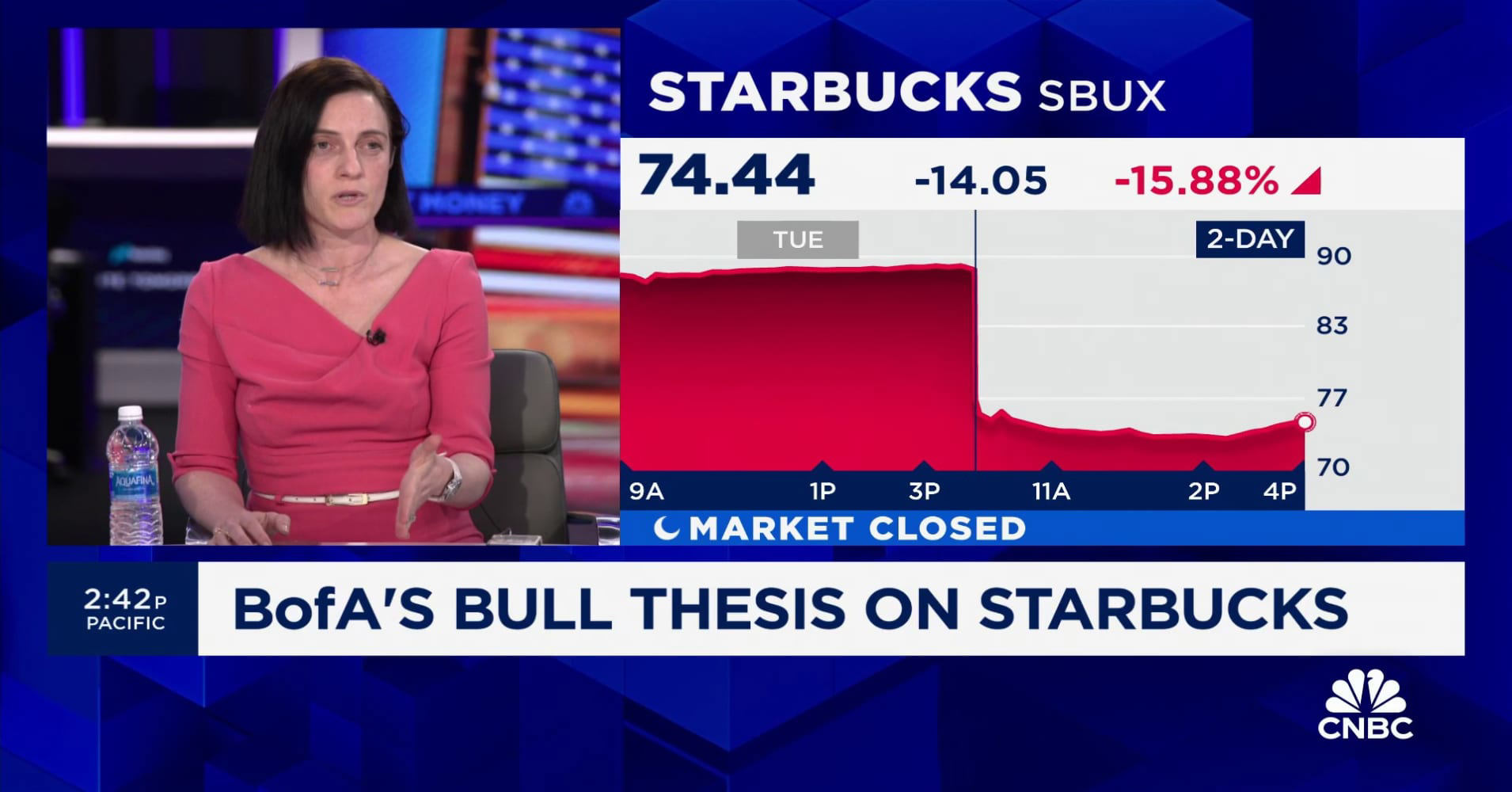

Stock Market Valuations Bof A Explains Why Investors Shouldnt Worry

Apr 26, 2025

Stock Market Valuations Bof A Explains Why Investors Shouldnt Worry

Apr 26, 2025 -

An American Battleground A High Stakes Showdown With Global Wealth

Apr 26, 2025

An American Battleground A High Stakes Showdown With Global Wealth

Apr 26, 2025 -

Gambling On Calamity The Case Of The Los Angeles Wildfires

Apr 26, 2025

Gambling On Calamity The Case Of The Los Angeles Wildfires

Apr 26, 2025 -

Nfl Draft Day 1 Green Bays First Round Coverage

Apr 26, 2025

Nfl Draft Day 1 Green Bays First Round Coverage

Apr 26, 2025 -

La Fires Landlords Accused Of Price Gouging Amid Crisis

Apr 26, 2025

La Fires Landlords Accused Of Price Gouging Amid Crisis

Apr 26, 2025