All-American Manufacturing: A Realistic Look At The Challenges

Table of Contents

The High Cost of Labor in the US

One of the most significant challenges confronting All-American Manufacturing is the high cost of labor. This isn't simply about wages; it encompasses the entire compensation package.

Minimum Wage and Benefits

- Increased labor costs: Rising minimum wages, while crucial for worker well-being, directly impact production costs. This makes American-made goods less price-competitive compared to those manufactured in countries with lower labor standards.

- Reduced competitiveness: The higher cost of labor can significantly reduce the competitiveness of All-American Manufacturing firms in the global marketplace, forcing them to either raise prices or absorb lower profit margins.

- Impact on profit margins: The squeeze on profit margins can hinder investment in innovation, modernization, and employee development, creating a vicious cycle.

- Challenges in attracting and retaining skilled workers: Even with competitive wages, attracting and retaining skilled workers remains a challenge, particularly for manufacturers competing with higher-paying industries.

Skilled Labor Shortages

The manufacturing sector is facing a growing skills gap. An aging workforce and a lack of interest among younger generations are contributing to significant labor shortages.

- Aging workforce: Many experienced manufacturing workers are nearing retirement, leading to a loss of institutional knowledge and expertise.

- Lack of young people entering the field: Manufacturing jobs are often perceived as less appealing than careers in technology or other sectors, leading to a dwindling pipeline of skilled workers.

- Need for apprenticeships and vocational training: Investing in robust apprenticeship programs and vocational training initiatives is crucial to developing a new generation of skilled manufacturers.

- Automation as a potential solution: While automation can address some labor shortages, it also requires retraining and upskilling existing workers to manage and maintain these advanced systems.

Competition from Overseas Markets

All-American Manufacturing faces fierce competition from overseas manufacturers, who often benefit from lower production costs and more relaxed regulations.

Lower Production Costs Abroad

Many countries offer significantly lower labor costs, less stringent environmental regulations, and access to cheaper raw materials, giving them a considerable cost advantage.

- Price competition: This intense price competition makes it difficult for All-American Manufacturing firms to maintain profitability, especially when competing against lower-priced imports.

- Offshoring: The allure of lower production costs has led many companies to offshore manufacturing, resulting in job losses and a decline in domestic production.

- Impact on domestic job creation: The loss of manufacturing jobs to overseas markets directly impacts domestic job creation and economic growth.

- Challenges of maintaining market share: Maintaining market share becomes an uphill battle when competing against manufacturers with significantly lower production costs.

Global Supply Chain Disruptions

Recent events have highlighted the vulnerabilities of relying heavily on global supply chains. Disruptions caused by pandemics, geopolitical instability, and natural disasters can severely impact production and profitability.

- Dependence on foreign parts: Many American manufacturers rely on imported parts and components, creating vulnerabilities in their supply chains.

- Transportation costs: Global shipping costs have increased dramatically, adding to the overall cost of production.

- Geopolitical instability: Political tensions and trade disputes can disrupt supply chains and increase uncertainty.

- The need for reshoring and nearshoring: Many companies are now exploring reshoring (bringing manufacturing back to the US) and nearshoring (moving manufacturing to nearby countries) to reduce their dependence on distant suppliers.

The Need for Technological Advancement and Automation

To remain competitive, All-American Manufacturing must embrace technological advancements and automation.

Investing in Automation and Robotics

Automation and robotics can significantly improve efficiency and productivity, but require substantial upfront investment.

- Initial investment costs: The high initial cost of implementing automation and robotics can be a barrier for smaller manufacturers.

- Long-term cost savings: Despite the initial investment, automation can lead to significant long-term cost savings through increased efficiency and reduced labor costs.

- Increased productivity: Automated systems can operate 24/7, boosting overall productivity and output.

- Job displacement concerns: The introduction of automation can lead to job displacement, requiring retraining and upskilling programs for affected workers.

- The need for retraining and upskilling: Workers need training to operate and maintain automated systems, highlighting the need for ongoing investment in workforce development.

Embracing Industry 4.0 Technologies

Adopting Industry 4.0 technologies, such as the Internet of Things (IoT), Artificial Intelligence (AI), and data analytics, is crucial for improving efficiency and flexibility.

- Improved data analysis: Data-driven insights can optimize production processes and identify areas for improvement.

- Predictive maintenance: AI-powered systems can predict equipment failures, reducing downtime and maintenance costs.

- Optimized production processes: Smart manufacturing technologies can optimize production flows, reducing waste and improving efficiency.

- Increased flexibility: Industry 4.0 technologies allow manufacturers to adapt quickly to changing market demands.

- The need for digital transformation skills: Implementing these technologies requires a skilled workforce capable of managing and maintaining complex systems.

Government Regulations and Policies

Government regulations and trade policies significantly impact the competitiveness of All-American Manufacturing.

Environmental Regulations

Environmental regulations are essential for sustainability but can also add to manufacturing costs.

- Compliance costs: Meeting environmental regulations can be expensive, particularly for smaller manufacturers with limited resources.

- Balancing environmental sustainability with economic viability: Finding a balance between environmental protection and economic competitiveness is a key challenge.

- Incentives for green manufacturing practices: Government incentives and tax breaks can encourage the adoption of more environmentally friendly manufacturing practices.

Trade Policies and Tariffs

Trade agreements and tariffs can significantly influence the competitiveness of All-American Manufacturing.

- Impact of import tariffs: Tariffs can protect domestic industries from foreign competition but can also lead to higher prices for consumers.

- Trade wars: Trade disputes and tariffs can disrupt supply chains and negatively impact manufacturing output.

- Negotiating favorable trade deals: Strong trade negotiations are essential to ensure fair competition and access to global markets.

- Protecting domestic industries: Government policies should focus on supporting and protecting domestic industries while fostering fair competition.

Conclusion

The challenges facing All-American Manufacturing are multifaceted and interconnected: high labor costs, intense global competition, the need for rapid technological adoption, and the complex landscape of government regulations all play a role. However, the path to revitalization isn't insurmountable. Investing in automation, reshoring operations, developing a skilled workforce through robust training programs, and advocating for supportive government policies are all crucial steps. Support All-American Manufacturing by investing in domestic companies, advocating for supportive government policies that foster innovation and fair competition, and promoting careers in the manufacturing sector. The future of All-American Manufacturing depends on our collective commitment to its success.

Featured Posts

-

Reliance Shares Surge Biggest Gain In 10 Months

Apr 29, 2025

Reliance Shares Surge Biggest Gain In 10 Months

Apr 29, 2025 -

Cancer Drug Setback Sends Akeso Shares Plummeting

Apr 29, 2025

Cancer Drug Setback Sends Akeso Shares Plummeting

Apr 29, 2025 -

Willie Nelsons 77th Solo Album A Pre 92nd Birthday Release

Apr 29, 2025

Willie Nelsons 77th Solo Album A Pre 92nd Birthday Release

Apr 29, 2025 -

Hengrui Pharma Secures China Approval For Hong Kong Ipo

Apr 29, 2025

Hengrui Pharma Secures China Approval For Hong Kong Ipo

Apr 29, 2025 -

Remembering Tragedy Louisville Residents Under Shelter In Place

Apr 29, 2025

Remembering Tragedy Louisville Residents Under Shelter In Place

Apr 29, 2025

Latest Posts

-

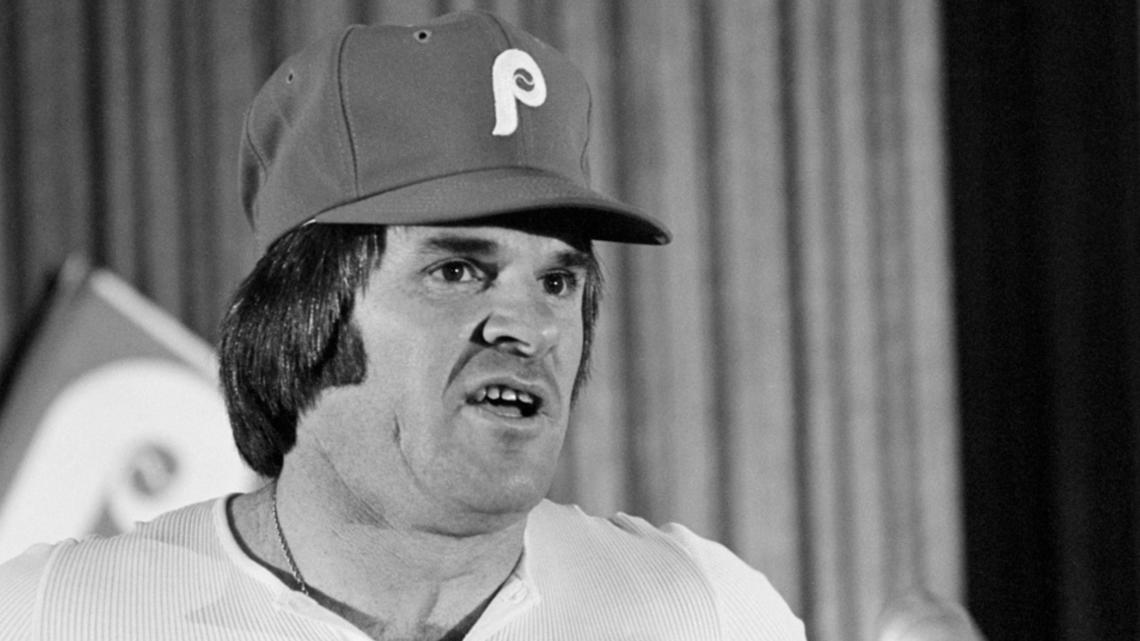

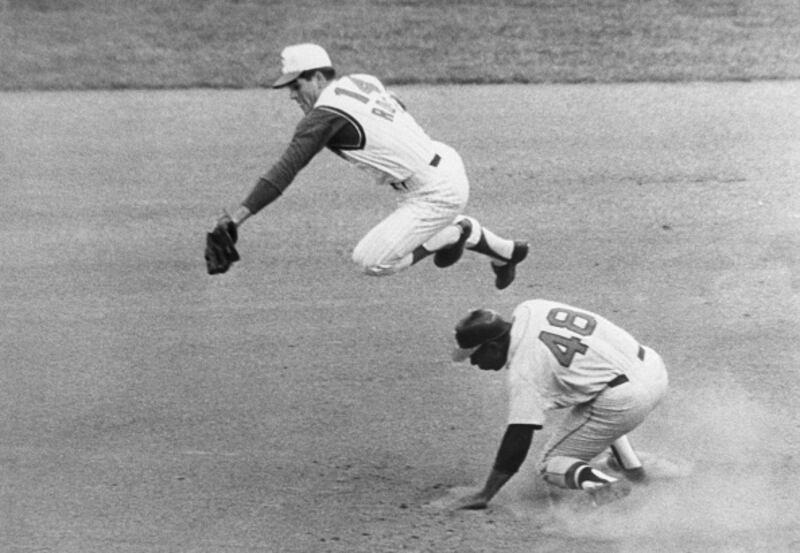

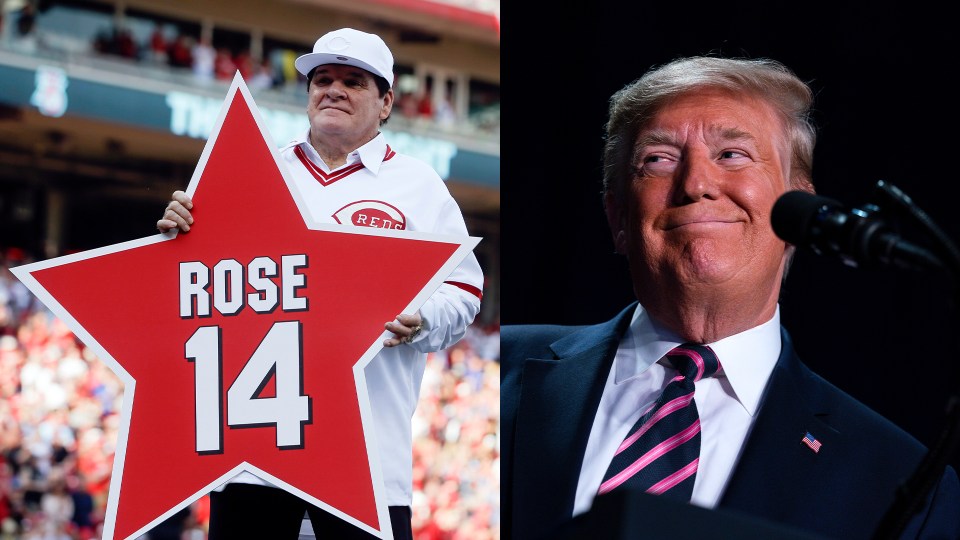

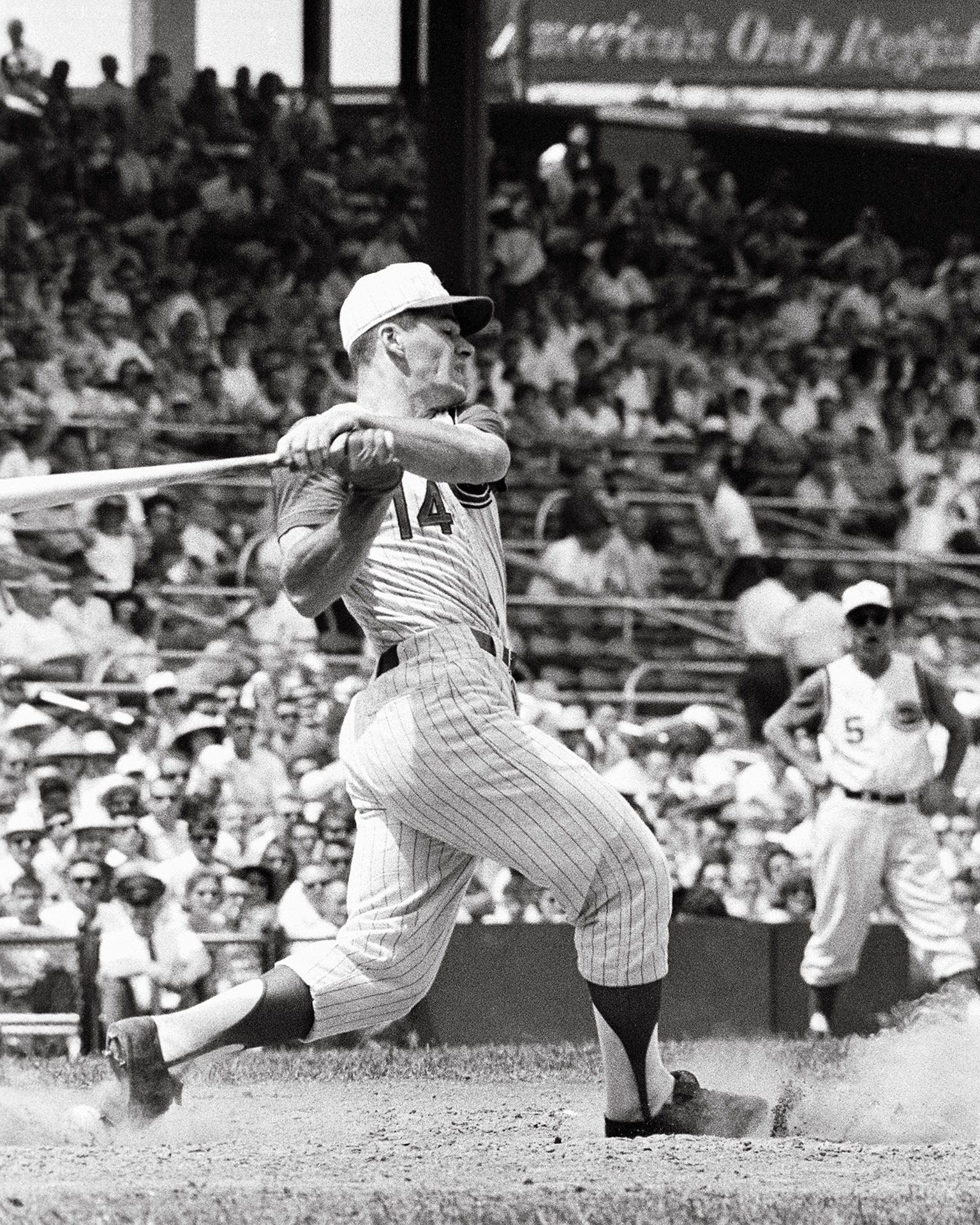

The Pete Rose Pardon Examining Trumps Potential Action And Its Fallout

Apr 29, 2025

The Pete Rose Pardon Examining Trumps Potential Action And Its Fallout

Apr 29, 2025 -

Rose Ban Trump Promises Posthumous Pardon Attacks Mlb

Apr 29, 2025

Rose Ban Trump Promises Posthumous Pardon Attacks Mlb

Apr 29, 2025 -

Will Trump Pardon Pete Rose A Call For Hall Of Fame Consideration

Apr 29, 2025

Will Trump Pardon Pete Rose A Call For Hall Of Fame Consideration

Apr 29, 2025 -

Will Pete Rose Be Pardoned Trumps Potential Decision Explained

Apr 29, 2025

Will Pete Rose Be Pardoned Trumps Potential Decision Explained

Apr 29, 2025 -

Trump On Pete Rose Mlb Decision Draws Presidential Ire

Apr 29, 2025

Trump On Pete Rose Mlb Decision Draws Presidential Ire

Apr 29, 2025