New Patent Leverages AI To Minimize Process Safety Hazards

Table of Contents

How AI Improves Process Safety Risk Assessment

Traditional risk assessments are time-consuming and often rely on historical data, potentially overlooking emerging hazards. This new patent utilizes AI algorithms to analyze vast datasets from various sources (sensor data, historical incidents, operational parameters) to provide a more comprehensive and accurate risk assessment. This AI-driven approach to process safety significantly improves hazard identification and risk quantification. The integration of quantitative risk assessment and qualitative risk assessment methodologies enhances the overall precision of the risk profile.

- Faster and more efficient hazard identification: AI algorithms can sift through massive datasets far quicker than human analysts, identifying potential hazards much faster.

- Improved accuracy in predicting potential failures: By analyzing historical data and operational parameters, AI can identify subtle patterns indicative of impending failures, something often missed in traditional methods.

- Identification of previously unseen or overlooked hazards: AI's ability to detect anomalies and unexpected patterns can uncover hidden hazards that might have been missed by human experts.

- Quantification of risk with greater precision: The AI provides a more nuanced understanding of risk by considering a wider range of variables and interactions, leading to more accurate risk quantification.

Machine Learning for Predictive Maintenance

The patent incorporates machine learning to predict equipment failures and potential safety hazards before they occur. By analyzing real-time sensor data from various sources, the AI can identify patterns indicating deteriorating equipment, allowing for proactive maintenance and preventing potential accidents. This predictive maintenance capability is a cornerstone of the improved AI safety the patent provides.

- Reduced downtime through preventative maintenance: By predicting failures, maintenance can be scheduled proactively, minimizing costly downtime.

- Proactive identification of potential equipment failures: The system alerts operators to potential issues before they escalate into major incidents.

- Minimized risk of catastrophic failures: Early detection and intervention significantly reduce the risk of catastrophic equipment failures and subsequent safety hazards.

- Extended equipment lifespan: Preventative maintenance, guided by AI predictions, extends the lifespan of equipment and reduces overall maintenance costs.

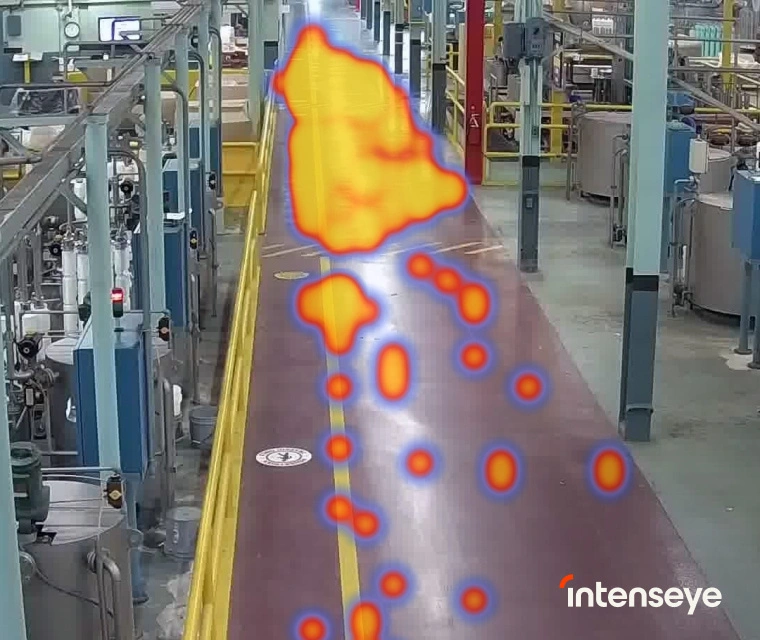

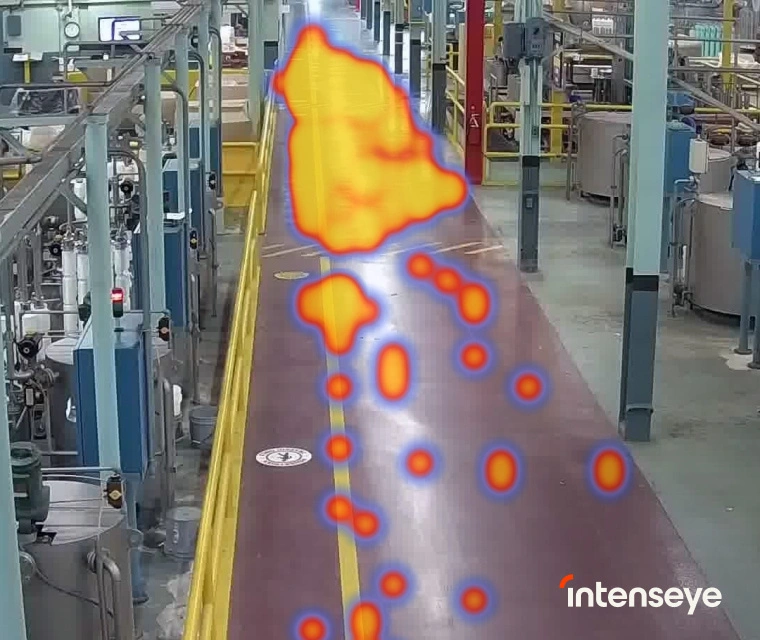

Real-time Monitoring and Alert System

The patented system provides real-time monitoring of critical process parameters. AI algorithms detect anomalies and deviations from established safety norms, immediately triggering alerts to operators. This enables rapid response to potential hazards, minimizing the impact of incidents. This real-time monitoring system is crucial for effective process safety management.

- Immediate notification of safety breaches: Operators are instantly alerted to any deviations from safe operating parameters.

- Faster response times to hazardous situations: Rapid notification allows for swift intervention, minimizing the impact of potential incidents.

- Reduced severity of incidents: Early detection and response significantly reduce the severity of incidents and potential damage.

- Improved operator situational awareness: The system provides operators with a comprehensive overview of the process, enhancing their situational awareness and decision-making capabilities.

The Impact on Process Safety Management (PSM) Systems

This AI-powered system enhances existing process safety management (PSM) systems by providing a more proactive and data-driven approach. It helps companies meet regulatory compliance requirements and build a stronger safety culture. This integration into existing PSM frameworks improves overall AI in process safety.

- Enhanced regulatory compliance: The system helps companies meet and exceed industry regulations and safety standards.

- Improved safety performance indicators: The data-driven approach allows for continuous monitoring and improvement of safety performance.

- Stronger safety culture and workforce engagement: The system empowers workers with better information and tools, fostering a stronger safety culture.

- Cost savings through reduced incidents and downtime: The proactive approach reduces the frequency and severity of incidents, leading to significant cost savings.

Conclusion

This new patent, leveraging AI to minimize process safety hazards, represents a significant leap forward in industrial safety. By combining advanced analytics, machine learning, and real-time monitoring, this technology offers a proactive and comprehensive approach to risk management. The benefits extend from faster and more accurate risk assessments to predictive maintenance and real-time hazard detection, ultimately leading to safer and more efficient industrial operations. Companies seeking to enhance their process safety management systems should explore the potential of this innovative technology and take steps towards adopting AI-powered solutions for a safer future. Learn more about how AI can revolutionize your approach to process safety and improve your overall process safety management.

Featured Posts

-

Former Ftc Commissioners Battle For Their Jobs

Apr 30, 2025

Former Ftc Commissioners Battle For Their Jobs

Apr 30, 2025 -

Outdated Software Hindering Your Ai Strategy

Apr 30, 2025

Outdated Software Hindering Your Ai Strategy

Apr 30, 2025 -

Jay Zs Super Bowl Family Moments Photos Of Blue Ivy And Rumi Carter

Apr 30, 2025

Jay Zs Super Bowl Family Moments Photos Of Blue Ivy And Rumi Carter

Apr 30, 2025 -

Noa Argamani At Time Gala A Call For The Return Of Israeli Hostages

Apr 30, 2025

Noa Argamani At Time Gala A Call For The Return Of Israeli Hostages

Apr 30, 2025 -

Document Amf Valeo 2025 E1027024 Contenu Et Implications 24 Mars 2025

Apr 30, 2025

Document Amf Valeo 2025 E1027024 Contenu Et Implications 24 Mars 2025

Apr 30, 2025